Fuqiang Cheng

Digital Twin Calibration for Biological System-of-Systems: Cell Culture Manufacturing Process

May 07, 2024

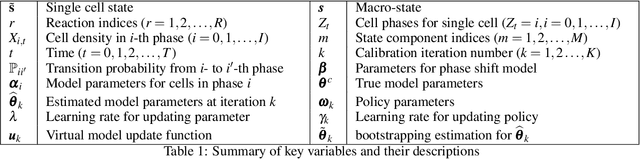

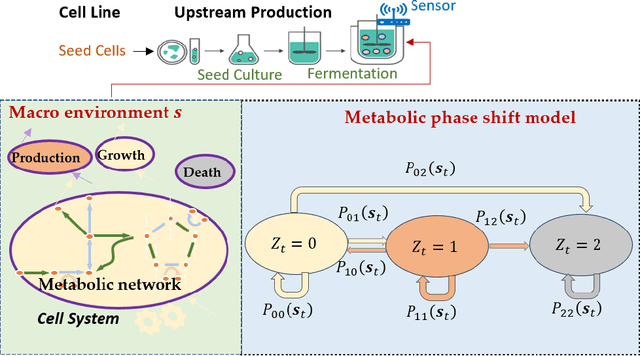

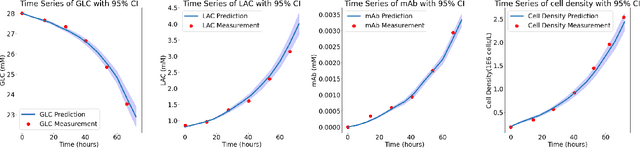

Abstract:Biomanufacturing innovation relies on an efficient design of experiments (DoE) to optimize processes and product quality. Traditional DoE methods, ignoring the underlying bioprocessing mechanisms, often suffer from a lack of interpretability and sample efficiency. This limitation motivates us to create a new optimal learning approach that can guide a sequential DoEs for digital twin model calibration. In this study, we consider a multi-scale mechanistic model for cell culture process, also known as Biological Systems-of-Systems (Bio-SoS), as our digital twin. This model with modular design, composed of sub-models, allows us to integrate data across various production processes. To calibrate the Bio-SoS digital twin, we evaluate the mean squared error of model prediction and develop a computational approach to quantify the impact of parameter estimation error of individual sub-models on the prediction accuracy of digital twin, which can guide sample-efficient and interpretable DoEs.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge