Barry Trimmer

Design and locomotion control of soft robot using friction manipulation and motor-tendon actuation

May 12, 2016

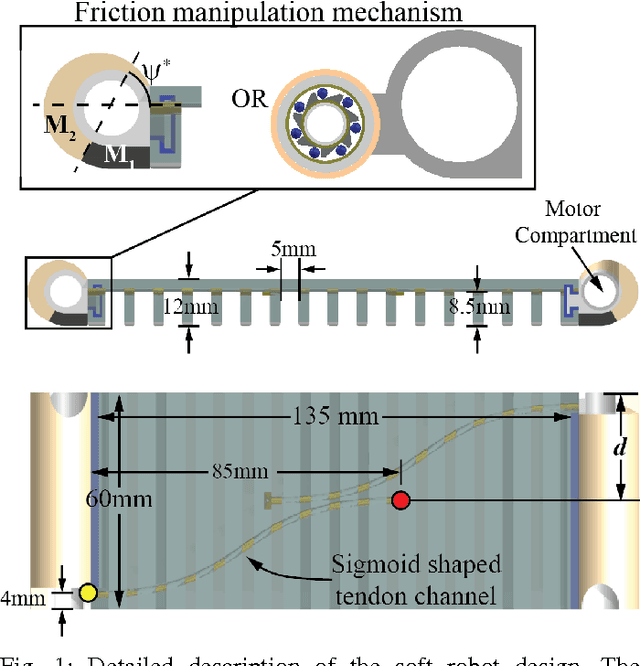

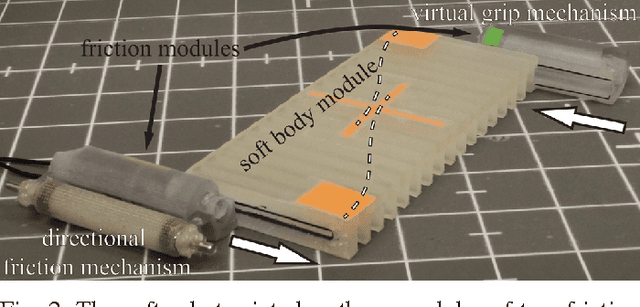

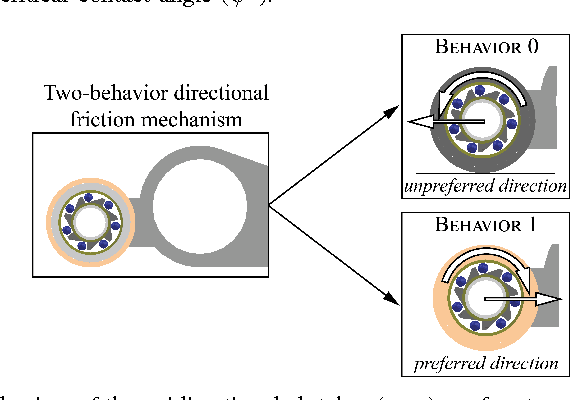

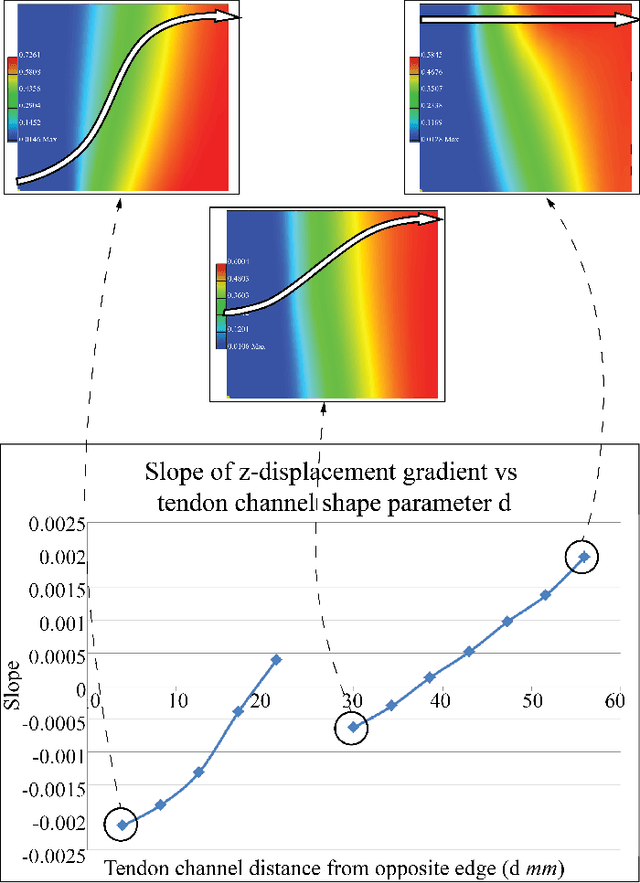

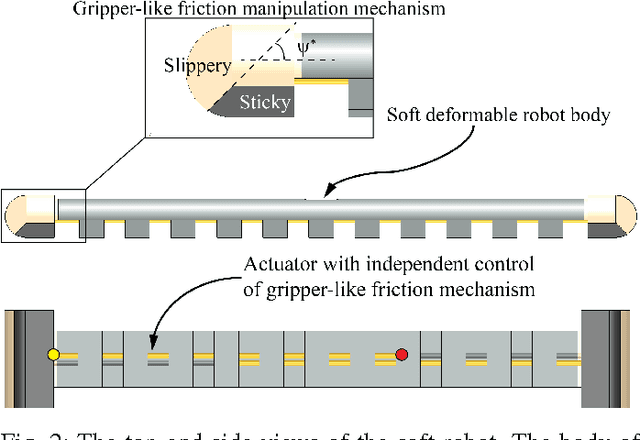

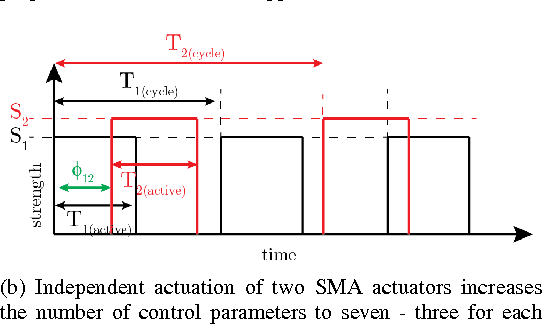

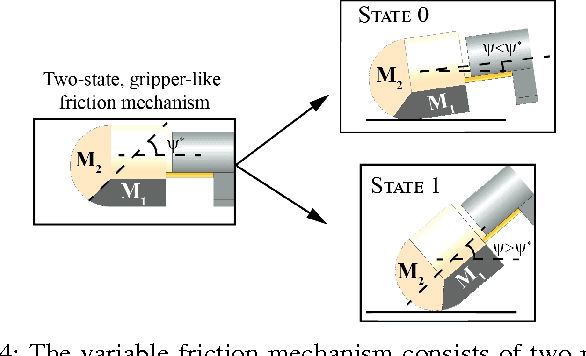

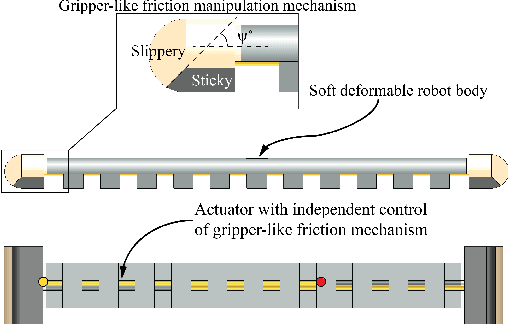

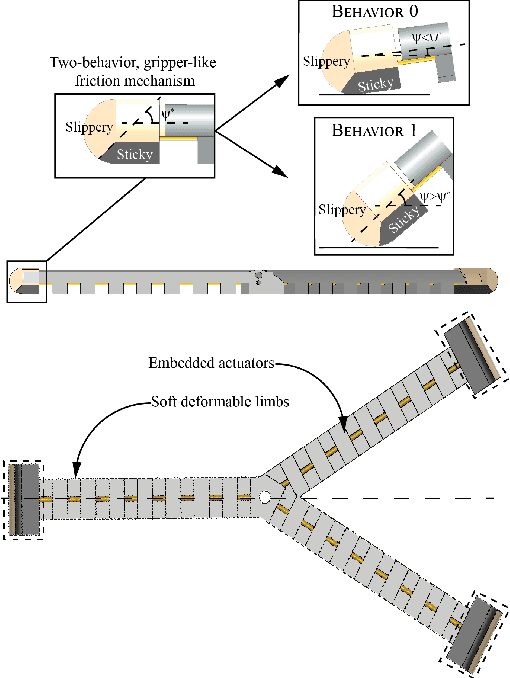

Abstract:Robots built from soft materials can alter their shape and size in a particular profile. This shape-changing ability could be extremely helpful for rescue robots and those operating in unknown terrains and environments. In changing shape, soft materials also store and release elastic energy, a feature that can be exploited for effective robot movement. However, design and control of these moving soft robots are non-trivial. The research presents design methodology for a 3D-printed, motor-tendon actuated soft robot capable of locomotion. In addition to shape change, the robot uses friction manipulation mechanisms to effect locomotion. The motor-tendon actuators comprise of nylon tendons embedded inside the soft body structure along a given path with one end fixed on the body and the other attached to a motor. These actuators directly control the deformation of the soft body which influences the robot locomotion behavior. Static stress analysis is used as a tool for designing the shape of the paths of these tendons embedded inside the body. The research also presents a novel model-free learning-based control approach for soft robots which interact with the environment at discrete contact points. This approach involves discretization of factors dominating robot-environment interactions as states, learning of the results as robot transitions between these robot states and evaluation of desired periodic state control sequences optimizing a cost function corresponding to a locomotion task (rotation or translation). The clever discretization allows the framework to exist in robot's task space, hence, facilitating calculation of control sequences without modeling the actuator, body material or details of the friction mechanisms. The flexibility of the framework is experimentally explored by applying it to robots with different friction mechanisms and different shapes of tendon paths.

Design and control of a soft, shape-changing, crawling robot

Sep 24, 2015

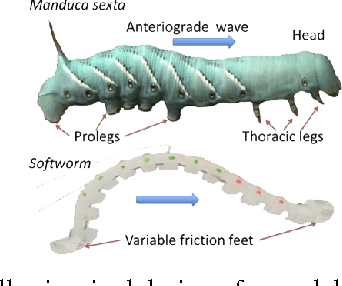

Abstract:Soft materials have many important roles in animal locomotion and object manipulation. In robotic applications soft materials can store and release energy, absorb impacts, increase compliance and increase the range of possible shape profiles using minimal actuators. The shape changing ability is also a potential tool to manipulate friction forces caused by contact with the environment. These advantages are accompanied by challenges of soft material actuation and the need to exploit frictional interactions to generate locomotion. Accordingly, the design of soft robots involves exploitation of continuum properties of soft materials for manipulating frictional interactions that result in robot locomotion. The research presents design and control of a soft body robot that uses its shape change capability for locomotion. The bioinspired (caterpillar) modular robot design is a soft monolithic body which interacts with the environment at discrete contact points (caterpillar prolegs). The deformable body is actuated by muscle-like shape memory alloy coils and the discrete contact points manipulate friction in a binary manner. This novel virtual grip mechanism combines two materials with different coefficients of frictions (sticky-slippery) to control the robot-environment friction interactions. The research also introduces a novel control concept that discretizes the robot-environment-friction interaction into binary states. This facilitates formulation of a control framework that is independent of the specific actuator or soft material properties and can be applied to multi-limbed soft robots. The transitions between individual robot states are assigned a reward that allow optimized state transition control sequences to be calculated. This conceptual framework is extremely versatile and we show how it can be applied to situations in which the robot loses limb function.

Model-free control framework for multi-limb soft robots

Sep 19, 2015

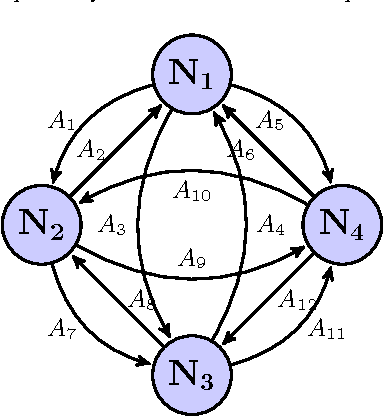

Abstract:The deformable and continuum nature of soft robots promises versatility and adaptability. However, control of modular, multi-limbed soft robots for terrestrial locomotion is challenging due to the complex robot structure, actuator mechanics and robot-environment interaction. Traditionally, soft robot control is performed by modeling kinematics using exact geometric equations and finite element analysis. The research presents an alternative, model-free, data-driven, reinforcement learning inspired approach, for controlling multi-limbed soft material robots. This control approach can be summarized as a four-step process of discretization, visualization, learning and optimization. The first step involves identification and subsequent discretization of key factors that dominate robot-environment, in turn, the robot control. Graph theory is used to visualize relationships and transitions between the discretized states. The graph representation facilitates mathematical definition of periodic control patterns (simple cycles) and locomotion gaits. Rewards corresponding to individual arcs of the graph are weighted displacement and orientation change for robot state-to-state transitions. These rewards are specific to surface of locomotion and are learned. Finally, the control patterns result from optimization of reward dependent locomotion task (e.g. translation) cost function. The optimization problem is an Integer Linear Programming problem which can be quickly solved using standard solvers. The framework is generic and independent of type of actuator, soft material properties or the type of friction mechanism, as the control exists in the robot's task space. Furthermore, the data-driven nature of the framework imparts adaptability to the framework toward different locomotion surfaces by re-learning rewards.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge