Artem Vasilyev

Anomaly segmentation model for defects detection in electroluminescence images of heterojunction solar cells

Aug 11, 2022

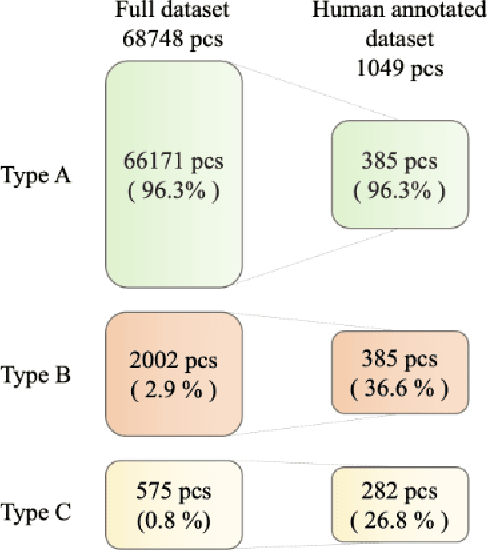

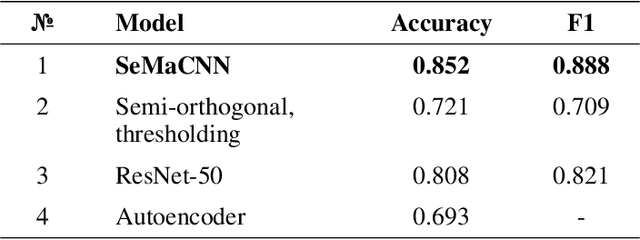

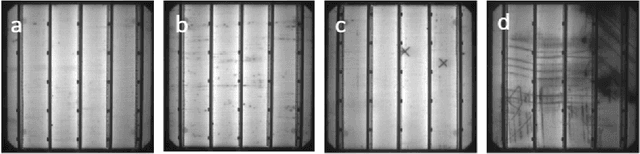

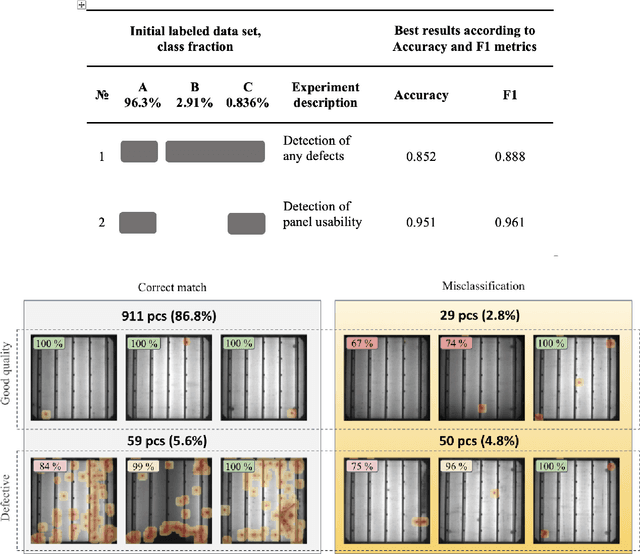

Abstract:Efficient defect detection in solar cell manufacturing is crucial for stable green energy technology manufacturing. This paper presents a deep-learning-based automatic detection model SeMaCNN for classification and semantic segmentation of electroluminescent images for solar cell quality evaluation and anomalies detection. The core of the model is an anomaly detection algorithm based on Mahalanobis distance that can be trained in a semi-supervised manner on imbalanced data with small number of digital electroluminescence images with relevant defects. This is particularly valuable for prompt model integration into the industrial landscape. The model has been trained with the on-plant collected dataset consisting of 68 748 electroluminescent images of heterojunction solar cells with a busbar grid. Our model achieves the accuracy of 92.5%, F1 score 95.8%, recall 94.8%, and precision 96.9% within the validation subset consisting of 1049 manually annotated images. The model was also tested on the open ELPV dataset and demonstrates stable performance with accuracy 94.6% and F1 score 91.1%. The SeMaCNN model demonstrates a good balance between its performance and computational costs, which make it applicable for integrating into quality control systems of solar cell manufacturing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge