Animesh

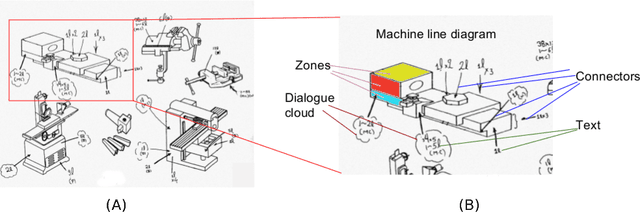

Reading Industrial Inspection Sheets by Inferring Visual Relations

Dec 11, 2018

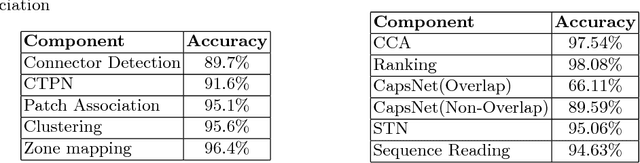

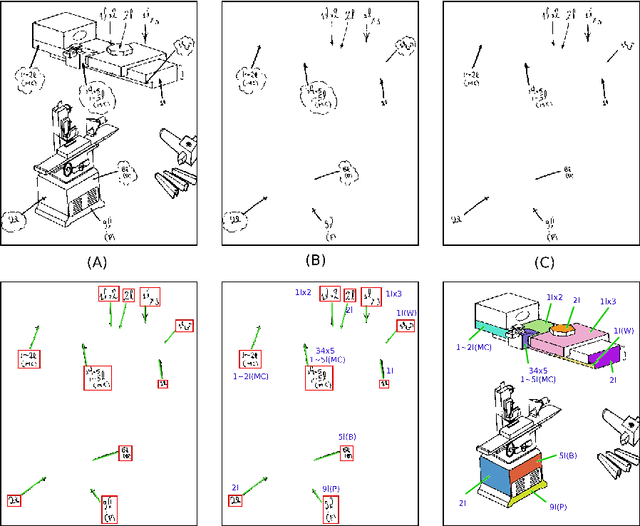

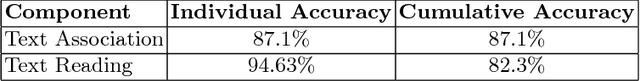

Abstract:The traditional mode of recording faults in heavy factory equipment has been via hand marked inspection sheets, wherein a machine engineer manually marks the faulty machine regions on a paper outline of the machine. Over the years, millions of such inspection sheets have been recorded and the data within these sheets has remained inaccessible. However, with industries going digital and waking up to the potential value of fault data for machine health monitoring, there is an increased impetus towards digitization of these hand marked inspection records. To target this digitization, we propose a novel visual pipeline combining state of the art deep learning models, with domain knowledge and low level vision techniques, followed by inference of visual relationships. Our framework is robust to the presence of both static and non-static background in the document, variability in the machine template diagrams, unstructured shape of graphical objects to be identified and variability in the strokes of handwritten text. The proposed pipeline incorporates a capsule and spatial transformer network based classifier for accurate text reading, and a customized CTPN network for text detection in addition to hybrid techniques for arrow detection and dialogue cloud removal. We have tested our approach on a real world dataset of 50 inspection sheets for large containers and boilers. The results are visually appealing and the pipeline achieved an accuracy of 87.1% for text detection and 94.6% for text reading.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge