Angus B. Clark

Malleable Robots

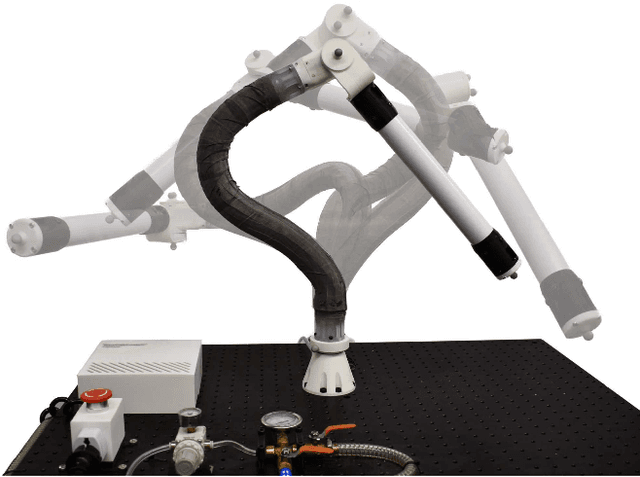

Feb 06, 2025Abstract:This chapter is about the fundamentals of fabrication, control, and human-robot interaction of a new type of collaborative robotic manipulators, called malleable robots, which are based on adjustable architectures of varying stiffness for achieving high dexterity with lower mobility arms. Collaborative robots, or cobots, commonly integrate six or more degrees of freedom (DOF) in a serial arm in order to allow positioning in constrained spaces and adaptability across tasks. Increasing the dexterity of robotic arms has been indeed traditionally accomplished by increasing the number of degrees of freedom of the system; however, once a robotic task has been established (e.g., a pick-and-place operation), the motion of the end-effector can be normally achieved using less than 6-DOF (i.e., lower mobility). The aim of malleable robots is to close the technological gap that separates current cobots from achieving flexible, accessible manufacturing automation with a reduced number of actuators.

* 37 pages, 22 figures, chapter 7 of "Handbook on Soft Robotics"

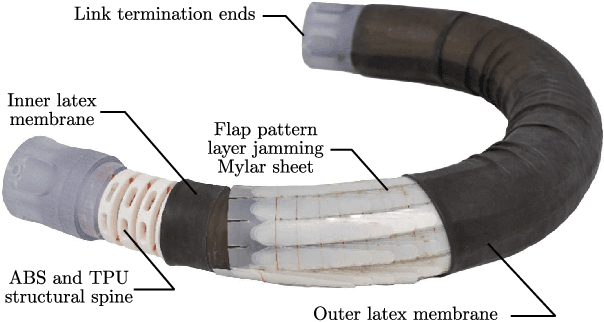

Stiffness-Tuneable Limb Segment with Flexible Spine for Malleable Robots

Apr 15, 2024Abstract:Robotic arms built from stiffness-adjustable, continuously bending segments serially connected with revolute joints have the ability to change their mechanical architecture and workspace, thus allowing high flexibility and adaptation to different tasks with less than six degrees of freedom, a concept that we call malleable robots. Known stiffening mechanisms may be used to implement suitable links for these novel robotic manipulators; however, these solutions usually show a reduced performance when bending due to structural deformation. By including an inner support structure this deformation can be minimised, resulting in an increased stiffening performance. This paper presents a new multi-material spine-inspired flexible structure for providing support in stiffness-controllable layer-jamming-based robotic links of large diameter. The proposed spine mechanism is highly movable with type and range of motions that match those of a robotic link using solely layer jamming, whilst maintaining a hollow and light structure. The mechanics and design of the flexible spine are explored, and a prototype of a link utilising it is developed and compared with limb segments based on granular jamming and layer jamming without support structure. Results of experiments verify the advantages of the proposed design, demonstrating that it maintains a constant central diameter across bending angles and presents an improvement of more than 203% of resisting force at 180 degrees.

* 7 pages, 11 figures

An Origami-Inspired Variable Friction Surface for Increasing the Dexterity of Robotic Grippers

Apr 15, 2024Abstract:While the grasping capability of robotic grippers has shown significant development, the ability to manipulate objects within the hand is still limited. One explanation for this limitation is the lack of controlled contact variation between the grasped object and the gripper. For instance, human hands have the ability to firmly grip object surfaces, as well as slide over object faces, an aspect that aids the enhanced manipulation of objects within the hand without losing contact. In this letter, we present a parametric, origami-inspired thin surface capable of transitioning between a high friction and a low friction state, suitable for implementation as an epidermis in robotic fingers. A numerical analysis of the proposed surface based on its design parameters, force analysis, and performance in in-hand manipulation tasks is presented. Through the development of a simple two-fingered two-degree-of-freedom gripper utilizing the proposed variable-friction surfaces with different parameters, we experimentally demonstrate the improved manipulation capabilities of the hand when compared to the same gripper without changeable friction. Results show that the pattern density and valley gap are the main parameters that effect the in-hand manipulation performance. The origami-inspired thin surface with a higher pattern density generated a smaller valley gap and smaller height change, producing a more stable improvement of the manipulation capabilities of the hand.

* 8 pages, 11 figures

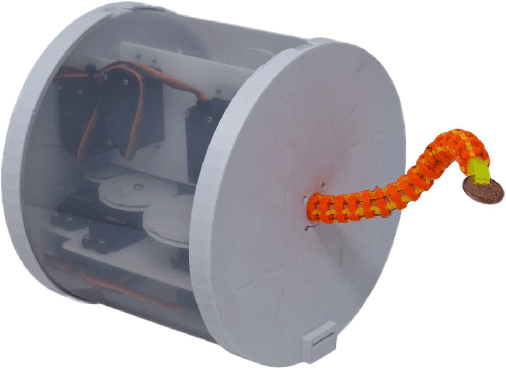

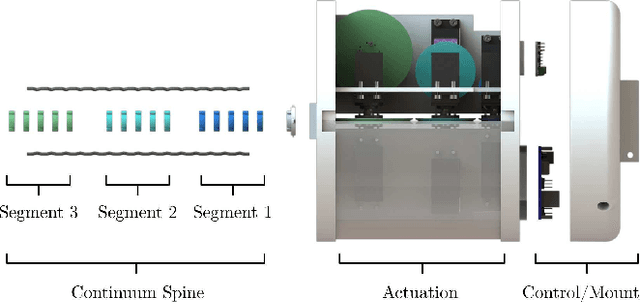

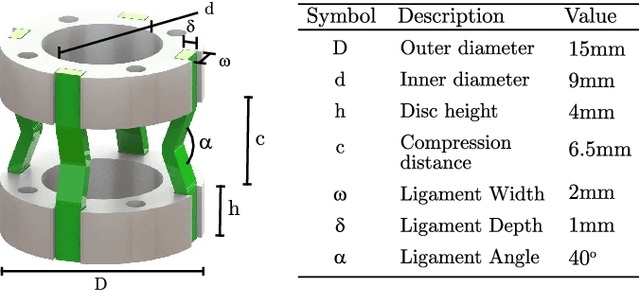

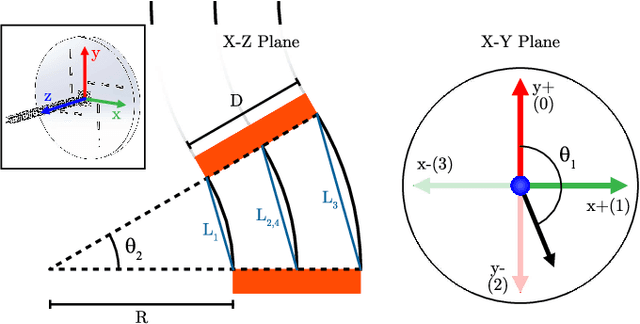

A Continuum Manipulator for Open-Source Surgical Robotics Research and Shared Development

Jan 04, 2021

Abstract:Many have explored the application of continuum robot manipulators for minimally invasive surgery, and have successfully demonstrated the advantages their flexible design provides -- with some solutions having reached commercialisation and clinical practice. However, the usual high complexity and closed-nature of such designs has traditionally restricted the shared development of continuum robots across the research area, thus impacting further progress and the solution of open challenges. In order to close this gap, this paper introduces ENDO, an open-source 3-segment continuum robot manipulator with control and actuation mechanism, whose focus is on simplicity, affordability, and accessibility. This robotic system is fabricated from low cost off-the-shelf components and rapid prototyping methods, and its information for implementation (and that of future iterations), including CAD files and source code, is available to the public on the Open Source Medical Robots initiative's repository on GitHub (https://github.com/OpenSourceMedicalRobots), with the control library also available directly from Arduino. Herein, we present details of the robot design and control, validate functionality by experimentally evaluating its workspace, and discuss possible paths for future development.

Design and Workspace Characterisation of Malleable Robots

Sep 14, 2020

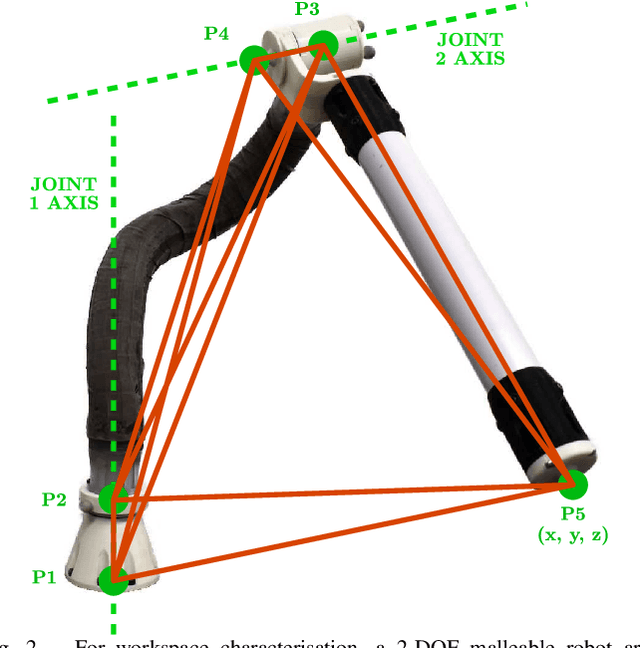

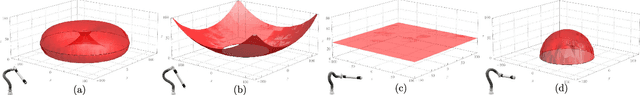

Abstract:For the majority of tasks performed by traditional serial robot arms, such as bin picking or pick and place, only two or three degrees of freedom (DOF) are required for motion; however, by augmenting the number of degrees of freedom, further dexterity of robot arms for multiple tasks can be achieved. Instead of increasing the number of joints of a robot to improve flexibility and adaptation, which increases control complexity, weight, and cost of the overall system, malleable robots utilise a variable stiffness link between joints allowing the relative positioning of the revolute pairs at each end of the link to vary, thus enabling a low DOF serial robot to adapt across tasks by varying its workspace. In this paper, we present the design and prototyping of a 2-DOF malleable robot, calculate the general equation of its workspace using a parameterisation based on distance geometry---suitable for robot arms of variable topology, and characterise the workspace categories that the end effector of the robot can trace via reconfiguration. Through the design and construction of the malleable robot we explore design considerations, and demonstrate the viability of the overall concept. By using motion tracking on the physical robot, we show examples of the infinite number of workspaces that the introduced 2-DOF malleable robot can achieve.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge