Angelie Vincent

Bracketing brackets with bras and kets

Jul 31, 2020

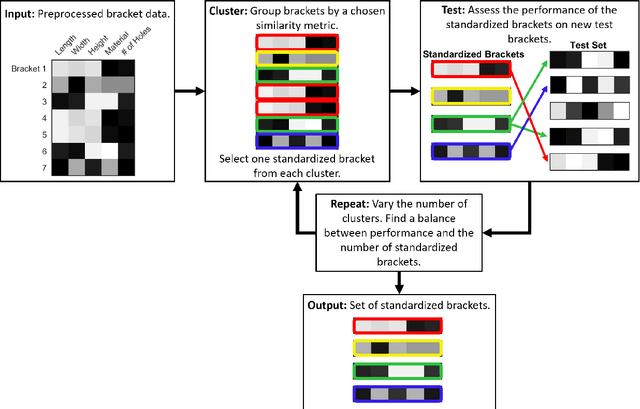

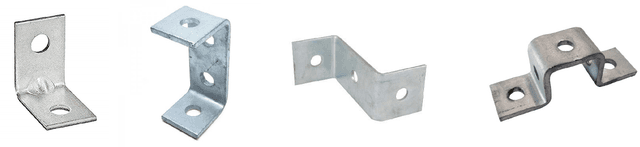

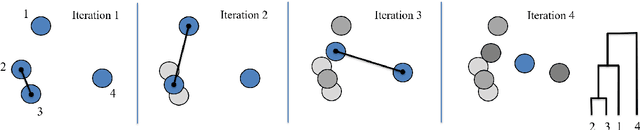

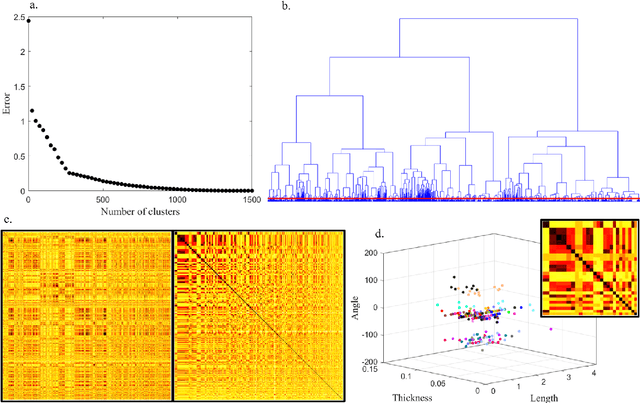

Abstract:Brackets are an essential component in aircraft manufacture and design, joining parts together, supporting weight, holding wires, and strengthening joints. Hundreds or thousands of unique brackets are used in every aircraft, but manufacturing a large number of distinct brackets is inefficient and expensive. Fortunately, many so-called "different" brackets are in fact very similar or even identical to each other. In this manuscript, we present a data-driven framework for constructing a comparatively small group of representative brackets from a large catalog of current brackets, based on hierarchical clustering of bracket data. We find that for a modern commercial aircraft, the full set of brackets can be reduced by 30\% while still describing half of the test set sufficiently accurately. This approach is based on designing an inner product that quantifies a multi-objective similarity between two brackets, which are the "bra" and the "ket" of the inner product. Although we demonstrate this algorithm to reduce the number of brackets in aerospace manufacturing, it may be generally applied to any large-scale component standardization effort.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge