Ange Wen

Experimental investigation of trans-scale displacement responses of wrinkle defects in fiber reinforced composite laminates

May 21, 2024

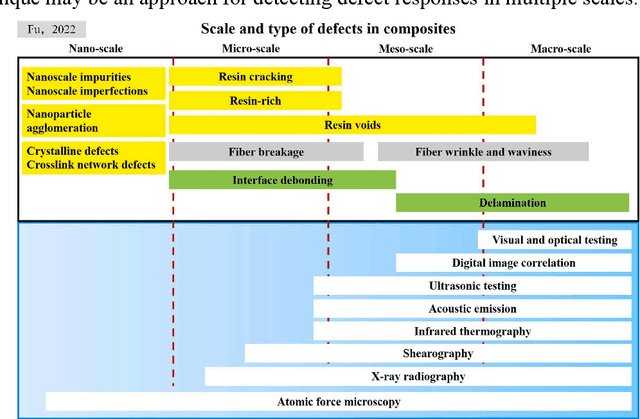

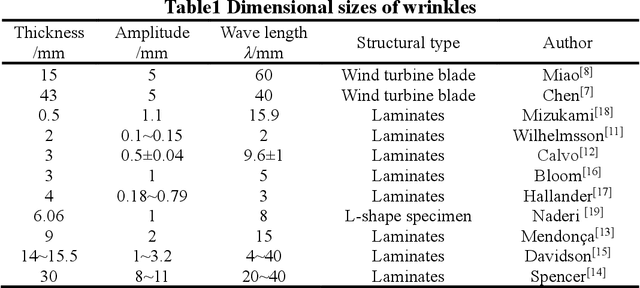

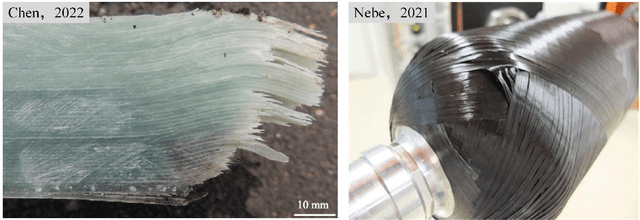

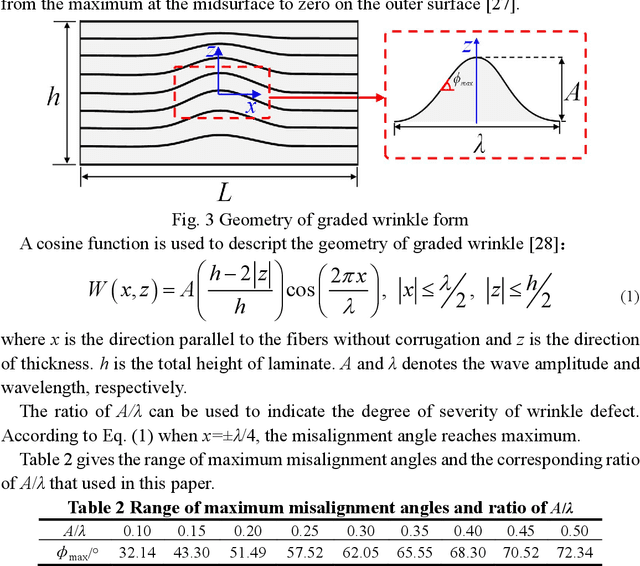

Abstract:Wrinkle defects were found widely exist in the field of industrial products, i.e. wind turbine blades and filament-wound composite pressure vessels. The magnitude of wrinkle wavelength varies from several millimeters to over one hundred millimeters. Locating the wrinkle defects and measuring their responses are very important to the assessment of the structures that containing wrinkle defects. A meso-mechanical modeling is presented based on the homogenization method to obtain the effective stiffness of a graded wrinkle. The finite element simulation predicts the trans-scale response of out-of-plane displacement of wrinkled laminates, where the maximum displacement ranges from nanoscale to millimeter scale. Such trans-scale effect requires different measurement approaches to observe the displacement responses. Here we employed Shearography (Speckle Pattern Shearing Interferometry) and fringe projection profilometry (FPP) method respectively according to the different magnitude of displacement. In FPP method, a displacement extraction algorithm was presented to obtain the out-of-plane displacement. The measurement sensitivity and accuracy of Shearography and FPP are compared, which provides a quantitative reference for industrial non-destructive test.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge