Ahmad Rafsanjani

Tailoring materials into kirigami robots

Oct 08, 2025Abstract:Kirigami, the traditional paper-cutting craft, holds immense potential for revolutionizing robotics by providing multifunctional, lightweight, and adaptable solutions. Kirigami structures, characterized by their bending-dominated deformation, offer resilience to tensile forces and facilitate shape morphing under small actuation forces. Kirigami components such as actuators, sensors, batteries, controllers, and body structures can be tailored to specific robotic applications by optimizing cut patterns. Actuators based on kirigami principles exhibit complex motions programmable through various energy sources, while kirigami sensors bridge the gap between electrical conductivity and compliance. Kirigami-integrated batteries enable energy storage directly within robot structures, enhancing flexibility and compactness. Kirigami-controlled mechanisms mimic mechanical computations, enabling advanced functionalities such as shape morphing and memory functions. Applications of kirigami-enabled robots include grasping, locomotion, and wearables, showcasing their adaptability to diverse environments and tasks. Despite promising opportunities, challenges remain in the design of cut patterns for a given function and streamlining fabrication techniques.

Multimodal Limbless Crawling Soft Robot with a Kirigami Skin

Jun 05, 2025Abstract:Limbless creatures can crawl on flat surfaces by deforming their bodies and interacting with asperities on the ground, offering a biological blueprint for designing efficient limbless robots. Inspired by this natural locomotion, we present a soft robot capable of navigating complex terrains using a combination of rectilinear motion and asymmetric steering gaits. The robot is made of a pair of antagonistic inflatable soft actuators covered with a flexible kirigami skin with asymmetric frictional properties. The robot's rectilinear locomotion is achieved through cyclic inflation of internal chambers with precise phase shifts, enabling forward progression. Steering is accomplished using an asymmetric gait, allowing for both in-place rotation and wide turns. To validate its mobility in obstacle-rich environments, we tested the robot in an arena with coarse substrates and multiple obstacles. Real-time feedback from onboard proximity sensors, integrated with a human-machine interface (HMI), allowed adaptive control to avoid collisions. This study highlights the potential of bioinspired soft robots for applications in confined or unstructured environments, such as search-and-rescue operations, environmental monitoring, and industrial inspections.

Proprioceptive Origami Manipulator

Feb 10, 2025

Abstract:Origami offers a versatile framework for designing morphable structures and soft robots by exploiting the geometry of folds. Tubular origami structures can act as continuum manipulators that balance flexibility and strength. However, precise control of such manipulators often requires reliance on vision-based systems that limit their application in complex and cluttered environments. Here, we propose a proprioceptive tendon-driven origami manipulator without compromising its flexibility. Using conductive threads as actuating tendons, we multiplex them with proprioceptive sensing capabilities. The change in the active length of the tendons is reflected in their effective resistance, which can be measured with a simple circuit. We correlated the change in the resistance to the lengths of the tendons. We input this information into a forward kinematic model to reconstruct the manipulator configuration and end-effector position. This platform provides a foundation for the closed-loop control of continuum origami manipulators while preserving their inherent flexibility.

Inflatable Kirigami Crawlers

Feb 10, 2025

Abstract:Kirigami offers unique opportunities for guided morphing by leveraging the geometry of the cuts. This work presents inflatable kirigami crawlers created by introducing cut patterns into heat-sealable textiles to achieve locomotion upon cyclic pneumatic actuation. Inflating traditional air pouches results in symmetric bulging and contraction. In inflated kirigami actuators, the accumulated compressive forces uniformly break the symmetry, enhance contraction compared to simple air pouches by two folds, and trigger local rotation of the sealed edges that overlap and self-assemble into an architected surface with emerging scale-like features. As a result, the inflatable kirigami actuators exhibit a uniform, controlled contraction with asymmetric localized out-of-plane deformations. This process allows us to harness the geometric and material nonlinearities to imbue inflatable textile-based kirigami actuators with predictable locomotive functionalities. We thoroughly characterized the programmed deformations of these actuators and their impact on friction. We found that the kirigami actuators exhibit directional anisotropic friction properties when inflated, having higher friction coefficients against the direction of the movement, enabling them to move across surfaces with varying roughness. We further enhanced the functionality of inflatable kirigami actuators by introducing multiple channels and segments to create functional soft robotic prototypes with versatile locomotion capabilities.

Weld n'Cut: Automated fabrication of inflatable fabric actuators

Feb 10, 2025

Abstract:Lightweight, durable textile-based inflatable soft actuators are widely used in soft robotics, particularly for wearable robots in rehabilitation and in enhancing human performance in demanding jobs. Fabricating these actuators typically involves multiple steps: heat-sealable fabrics are fused with a heat press, and non-stick masking layers define internal chambers. These layers must be carefully removed post-fabrication, often making the process labor-intensive and prone to errors. To address these challenges and improve the accuracy and performance of inflatable actuators, we introduce the Weld n'Cut platform-an open-source, automated manufacturing process that combines ultrasonic welding for fusing textile layers with an oscillating knife for precise cuts, enabling the creation of complex inflatable structures. We demonstrate the machine's performance across various materials and designs with arbitrarily complex geometries.

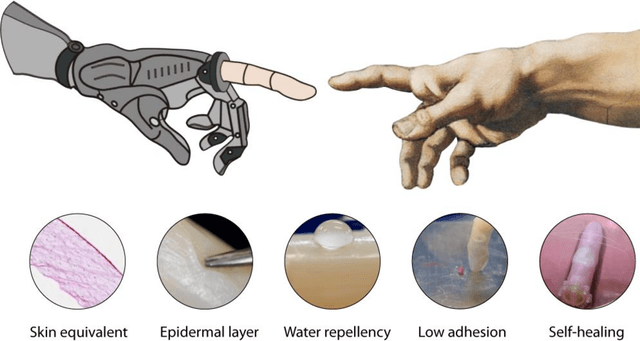

Giving life to robotic skins

Jan 05, 2023

Abstract:The skin of humanoid robots often lacks human tactility and the inherent self-repair capability of biological tissues. Recently, researchers have grown a living, self-healing skin on a robot finger by subsequent culturing of human dermal and epidermal cells. Here, we highlight the significance of this study alongside challenges toward developing biohybrid robots equipped with sensate and adaptive living robotic skins.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge