Abbas Rashidi

Gaby

Using Unmanned Aerial Systems (UAS) for Assessing and Monitoring Fall Hazard Prevention Systems in High-rise Building Projects

Sep 27, 2022

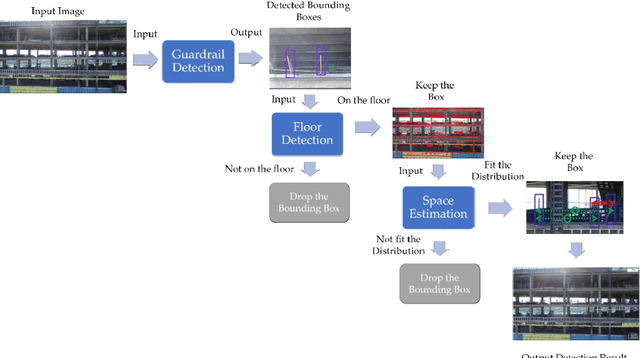

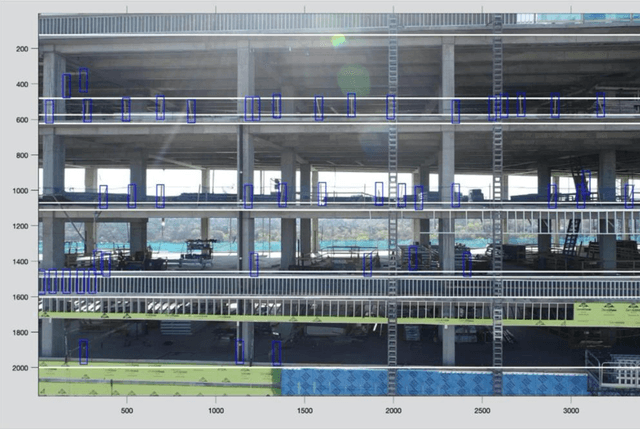

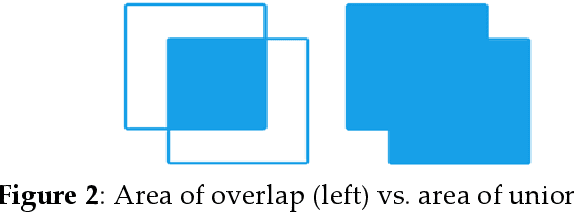

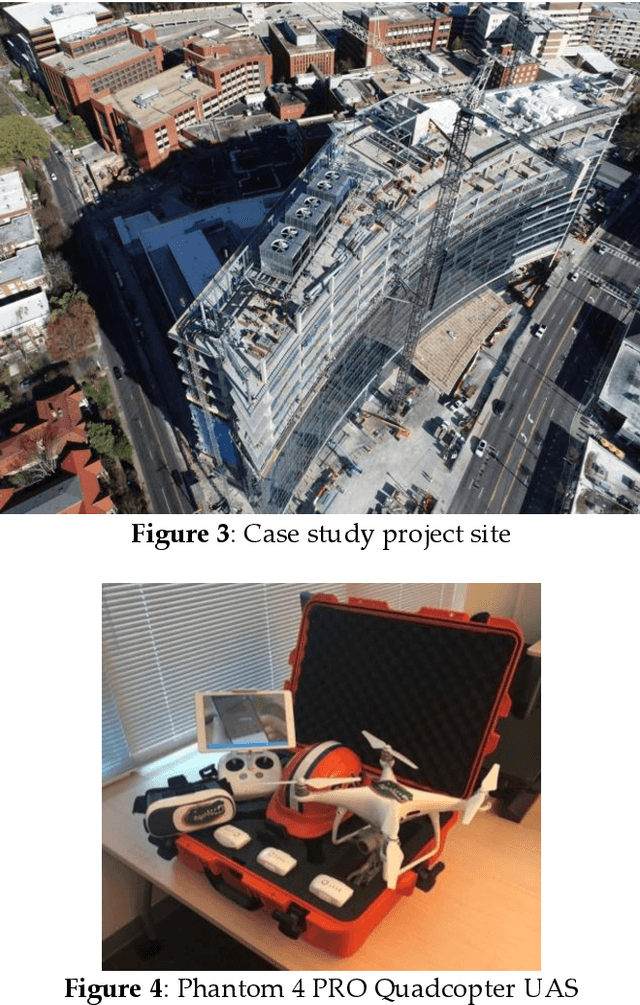

Abstract:This study develops a framework for unmanned aerial systems (UASs) to monitor fall hazard prevention systems near unprotected edges and openings in high-rise building projects. A three-step machine-learning-based framework was developed and tested to detect guardrail posts from the images captured by UAS. First, a guardrail detector was trained to localize the candidate locations of posts supporting the guardrail. Since images were used in this process collected from an actual job site, several false detections were identified. Therefore, additional constraints were introduced in the following steps to filter out false detections. Second, the research team applied a horizontal line detector to the image to properly detect floors and remove the detections that were not close to the floors. Finally, since the guardrail posts are installed with approximately normal distribution between each post, the space between them was estimated and used to find the most likely distance between the two posts. The research team used various combinations of the developed approaches to monitor guardrail systems in the captured images from a high-rise building project. Comparing the precision and recall metrics indicated that the cascade classifier achieves better performance with floor detection and guardrail spacing estimation. The research outcomes illustrate that the proposed guardrail recognition system can improve the assessment of guardrails and facilitate the safety engineer's task of identifying fall hazards in high-rise building projects.

Automated Translation of Rebar Information from GPR Data into As-Built BIM: A Deep Learning-based Approach

Oct 28, 2021

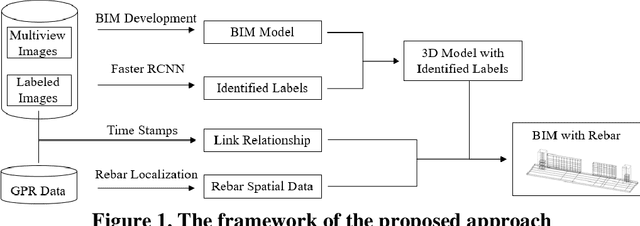

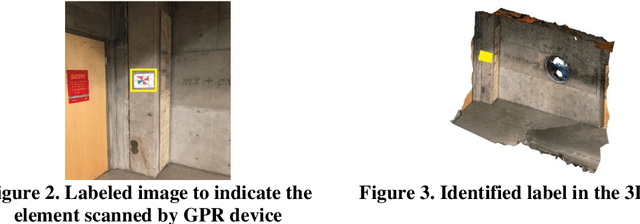

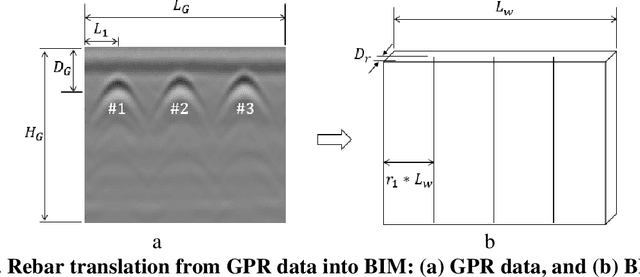

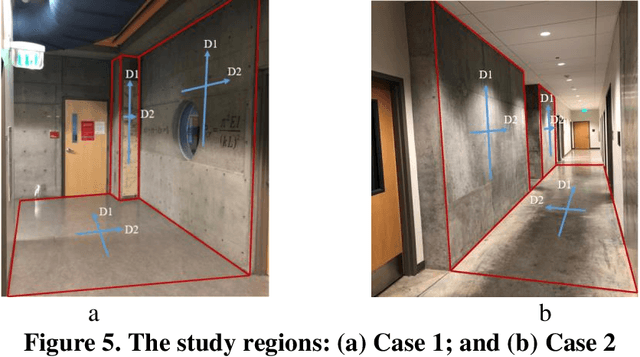

Abstract:Building Information Modeling (BIM) is increasingly used in the construction industry, but existing studies often ignore embedded rebars. Ground Penetrating Radar (GPR) provides a potential solution to develop as-built BIM with surface elements and rebars. However, automatically translating rebars from GPR into BIM is challenging since GPR cannot provide any information about the scanned element. Thus, we propose an approach to link GPR data and BIM according to Faster R-CNN. A label is attached to each element scanned by GPR for capturing the labeled images, which are used with other images to build a 3D model. Meanwhile, Faster R-CNN is introduced to identify the labels, and the projection relationship between images and the model is used to localize the scanned elements in the 3D model. Two concrete buildings is selected to evaluate the proposed approach, and the results reveal that our method could accurately translate the rebars from GPR data into corresponding elements in BIM with correct distributions.

An Innovative Approach to Determine Rebar Depth and Size by Comparing GPR Data with a Theoretical Database

May 19, 2020

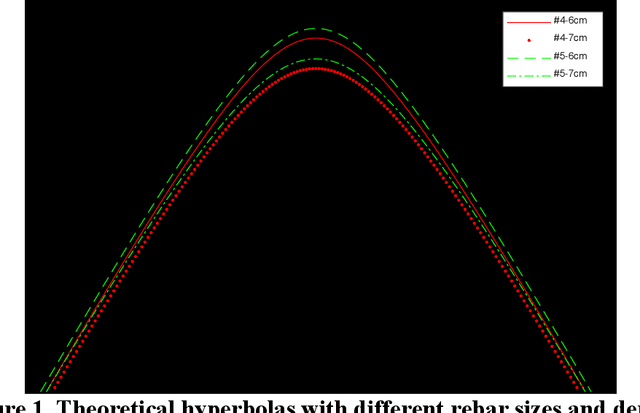

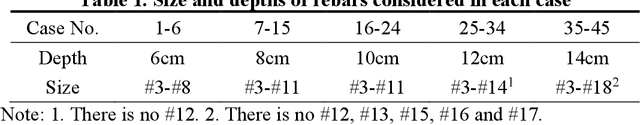

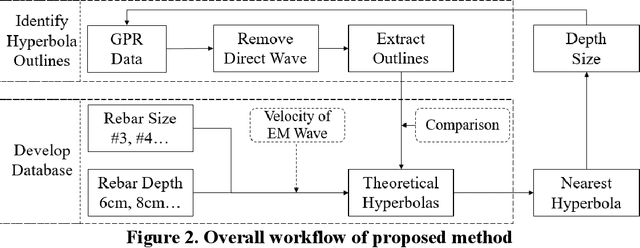

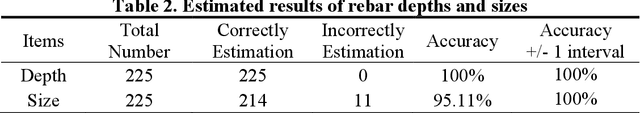

Abstract:Ground penetrating radar (GPR) is an efficient technique used for rapidly recognizing embedded rebar in concrete structures. However, due to the difficulty in extracting signals from GPR data and the intrinsic coupling between the rebar depth and size showing in the data, simultaneously determining rebar depth and size is challenging. This paper proposes an innovative algorithm to address this issue. First, the hyperbola signal from the GPR data is identified by direct wave removal, signal reconstruction and separation. Subsequently, a database is developed from a series of theoretical hyperbolas and then compared with the extracted hyperbola outlines. Finally, the rebar depth and size are determined by searching for the closest counterpart in the database. The obtained results are very promising and indicate that: (1) implementing the method presented in this paper can completely remove the direct wave noise from the GPR data, and can successfully extract the outlines from the interlaced hyperbolas; and (2) the proposed method can simultaneously determine the rebar depth and size with the accuracy of 100% and 95.11%, respectively.

An Improved Convolutional Neural Network System for Automatically Detecting Rebar in GPR Data

Jul 23, 2019

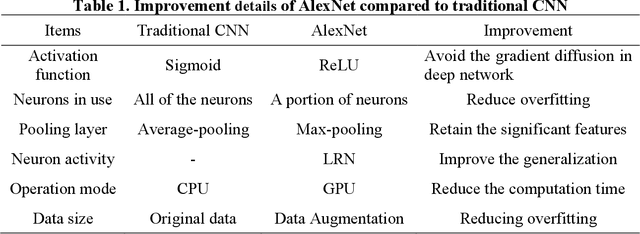

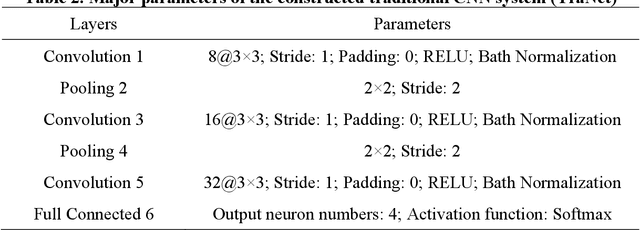

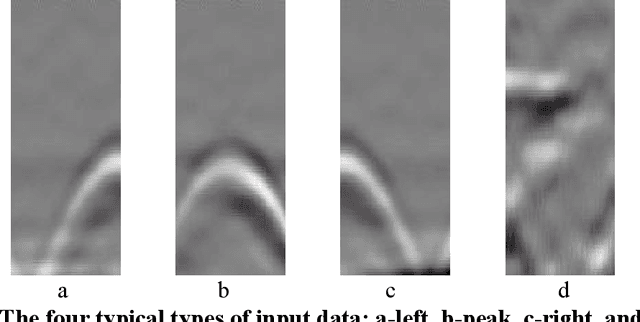

Abstract:As a mature technology, Ground Penetration Radar (GPR) is now widely employed in detecting rebar and other embedded elements in concrete structures. Manually recognizing rebar from GPR data is a time-consuming and error-prone procedure. Although there are several approaches to automatically detect rebar, it is still challenging to find a high resolution and efficient method for different rebar arrangements, especially for closely spaced rebar meshes. As an improved Convolution Neural Network (CNN), AlexNet shows superiority over traditional methods in image recognition domain. Thus, this paper introduces AlexNet as an alternative solution for automatically detecting rebar within GPR data. In order to show the efficiency of the proposed approach, a traditional CNN is built as the comparative option. Moreover, this research evaluates the impacts of different rebar arrangements and different window sizes on the accuracy of results. The results revealed that: (1) AlexNet outperforms the traditional CNN approach, and its superiority is more notable when the rebar meshes are densely distributed; (2) the detection accuracy significantly varies with changing the size of splitting window, and a proper window should contain enough information about rebar; (3) uniformly and sparsely distributed rebar meshes are more recognizable than densely or unevenly distributed items, due to lower chances of signal interferences.

Automated Activity Recognition of Construction Equipment Using a Data Fusion Approach

Jun 05, 2019

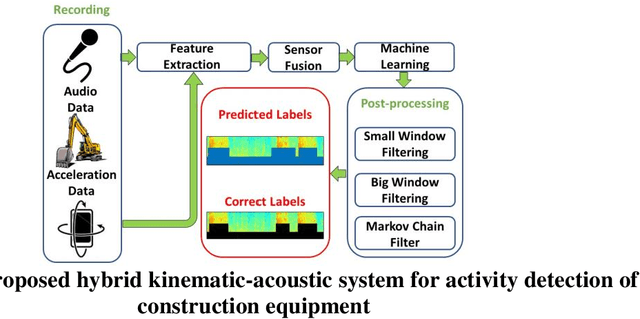

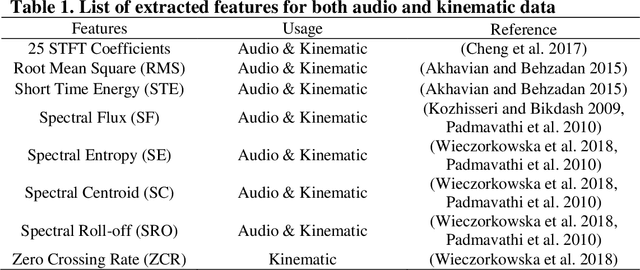

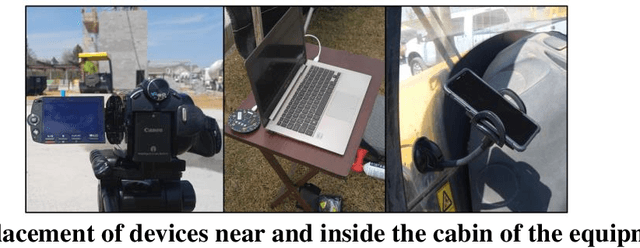

Abstract:Automated monitoring of construction operations, especially operations of equipment and machines, is an essential step toward cost-estimating, and planning of construction projects. In recent years, a number of methods were suggested for recognizing activities of construction equipment. These methods are based on processing single types of data (audio, visual, or kinematic data). Considering the complexity of construction jobsites, using one source of data is not reliable enough to cover all conditions and scenarios. To address the issue, we utilized a data fusion approach: This approach is based on collecting audio and kinematic data, and includes the following steps: 1) recording audio and kinematic data generated by machines, 2) preprocessing data, 3) extracting time- and frequency-domain-features, 4) feature-fusion, and 5) categorizing activities using a machine-learning algorithm. The proposed approach was implemented on multiple machines and the experiments show that it is possible to get up to 25% more-accurate results compared to cases of using single-data-sources.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge