Using Deep Reinforcement Learning for Zero Defect Smart Forging

Paper and Code

Jan 25, 2022

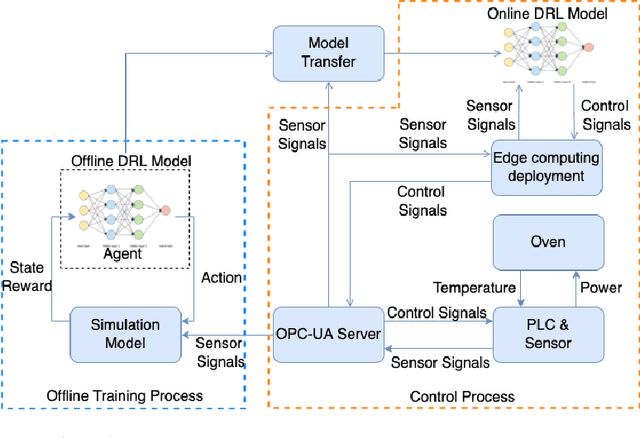

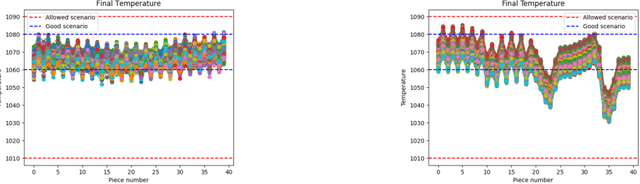

Defects during production may lead to material waste, which is a significant challenge for many companies as it reduces revenue and negatively impacts sustainability and the environment. An essential reason for material waste is a low degree of automation, especially in industries that currently have a low degree of digitalization, such as steel forging. Those industries typically rely on heavy and old machinery such as large induction ovens that are mostly controlled manually or using well-known recipes created by experts. However, standard recipes may fail when unforeseen events happen, such as an unplanned stop in production, which may lead to overheating and thus material degradation during the forging process. In this paper, we develop a digital twin-based optimization strategy for the heating process for a forging line to automate the development of an optimal control policy that adjusts the power for the heating coils in an induction oven based on temperature data observed from pyrometers. We design a digital twin-based deep reinforcement learning (DTRL) framework and train two different deep reinforcement learning (DRL) models for the heating phase using a digital twin of the forging line. The twin is based on a simulator that contains a heating transfer and movement model, which is used as an environment for the DRL training. Our evaluation shows that both models significantly reduce the temperature unevenness and can help to automate the traditional heating process.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge