Statistical Method to Model the Quality Inconsistencies of the Welding Process

Paper and Code

Feb 24, 2019

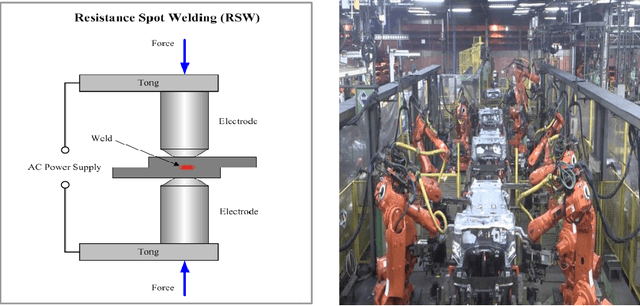

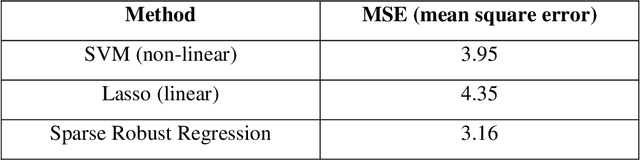

Resistance Spot Welding (RSW) is an important manufacturing process that attracts increasing attention in automotive industry. However, due to the complexity of the manufacturing process, the corresponding product quality shows significant inconsistencies even under the same process setup. This paper develops a statistical method to capture the inconsistence of welding quality measurements (e.g., nugget width) based on process parameters to efficiently monitor product quality. The proposed method provides engineering efficiency and cost saving benefit through reduction of physical testing required for weldability and verification. The developed method is applied to the real-world welding process.

* IISE Conference 2017

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge