Spatial-Temporal Bearing Fault Detection Using Graph Attention Networks and LSTM

Paper and Code

Oct 15, 2024

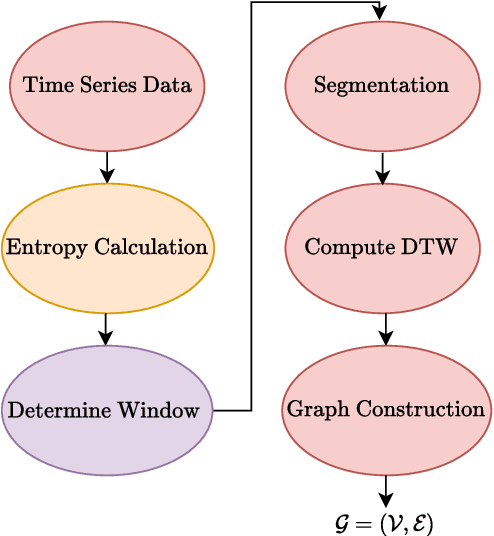

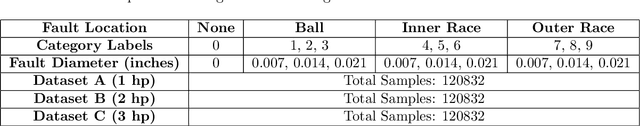

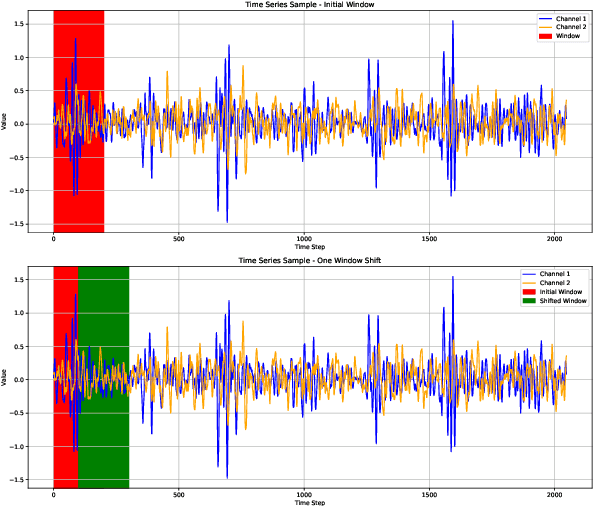

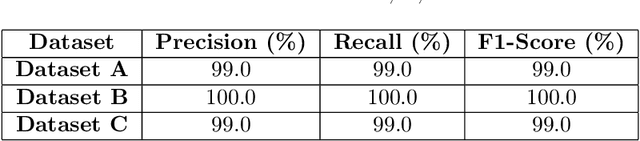

Purpose: This paper aims to enhance bearing fault diagnosis in industrial machinery by introducing a novel method that combines Graph Attention Network (GAT) and Long Short-Term Memory (LSTM) networks. This approach captures both spatial and temporal dependencies within sensor data, improving the accuracy of bearing fault detection under various conditions. Methodology: The proposed method converts time series sensor data into graph representations. GAT captures spatial relationships between components, while LSTM models temporal patterns. The model is validated using the Case Western Reserve University (CWRU) Bearing Dataset, which includes data under different horsepower levels and both normal and faulty conditions. Its performance is compared with methods such as K-Nearest Neighbors (KNN), Local Outlier Factor (LOF), Isolation Forest (IForest) and GNN-based method for bearing fault detection (GNNBFD). Findings: The model achieved outstanding results, with precision, recall, and F1-scores reaching 100\% across various testing conditions. It not only identifies faults accurately but also generalizes effectively across different operational scenarios, outperforming traditional methods. Originality: This research presents a unique combination of GAT and LSTM for fault detection, overcoming the limitations of traditional time series methods by capturing complex spatial-temporal dependencies. Its superior performance demonstrates significant potential for predictive maintenance in industrial applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge