Sparse neural networks with skip-connections for nonlinear system identification

Paper and Code

Jan 02, 2023

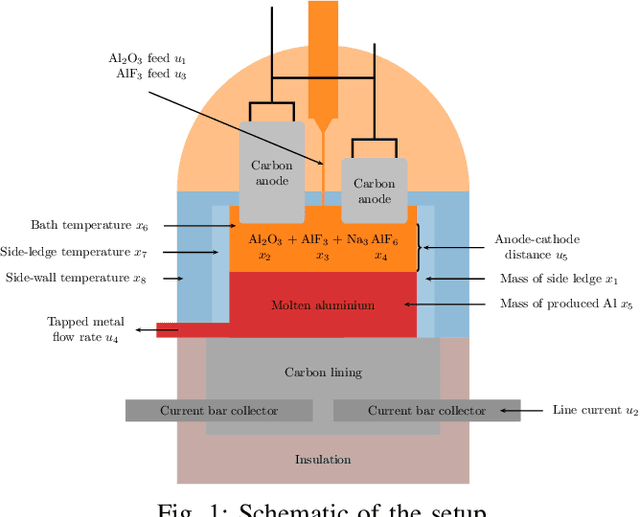

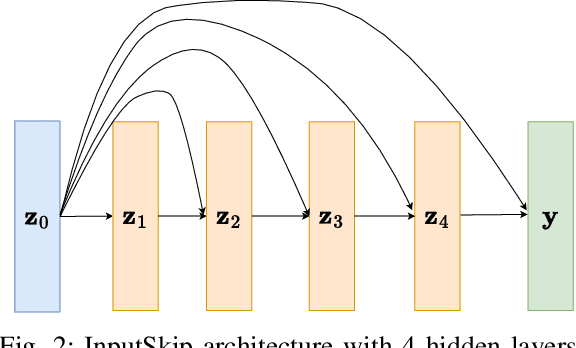

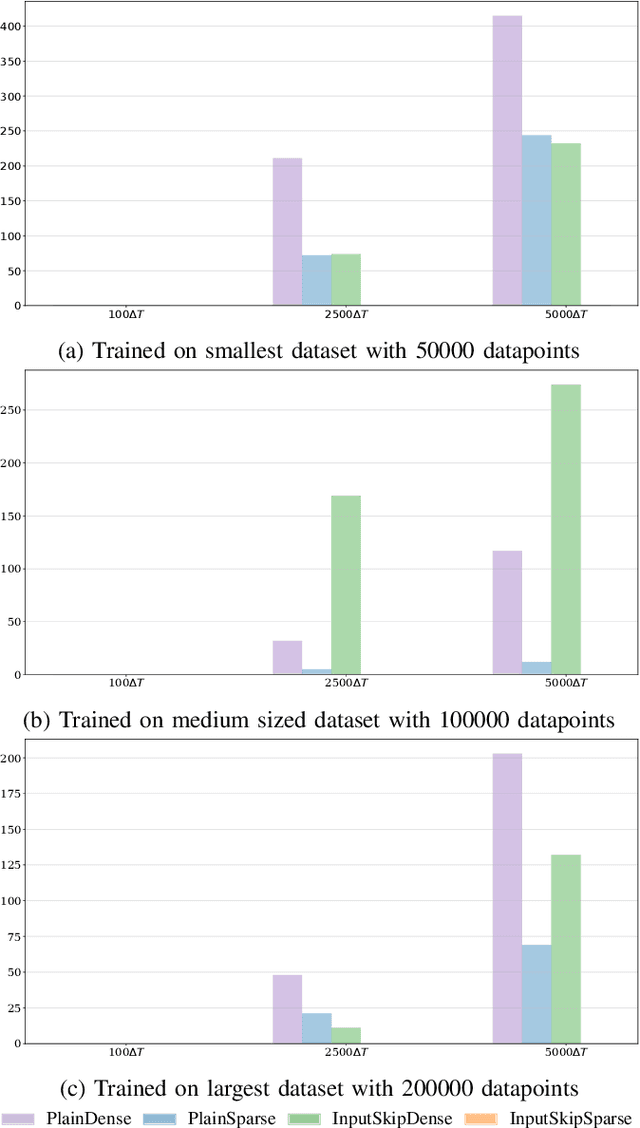

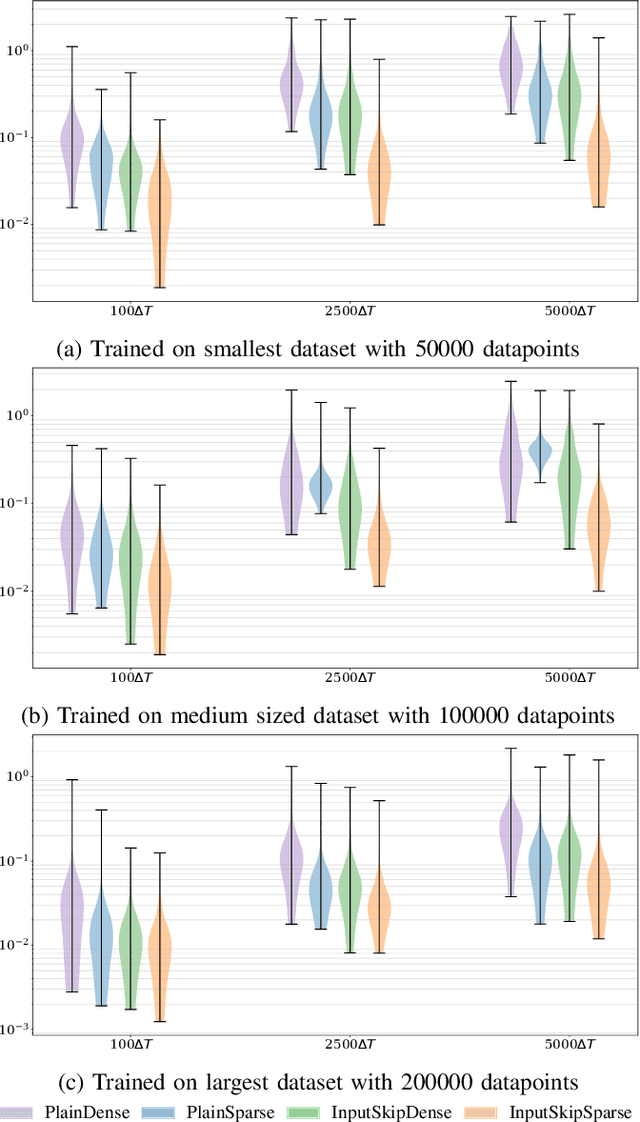

Data-driven models such as neural networks are being applied more and more to safety-critical applications, such as the modeling and control of cyber-physical systems. Despite the flexibility of the approach, there are still concerns about the safety of these models in this context, as well as the need for large amounts of potentially expensive data. In particular, when long-term predictions are needed or frequent measurements are not available, the open-loop stability of the model becomes important. However, it is difficult to make such guarantees for complex black-box models such as neural networks, and prior work has shown that model stability is indeed an issue. In this work, we consider an aluminum extraction process where measurements of the internal state of the reactor are time-consuming and expensive. We model the process using neural networks and investigate the role of including skip connections in the network architecture as well as using l1 regularization to induce sparse connection weights. We demonstrate that these measures can greatly improve both the accuracy and the stability of the models for datasets of varying sizes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge