Scalable AI Framework for Defect Detection in Metal Additive Manufacturing

Paper and Code

Nov 01, 2024

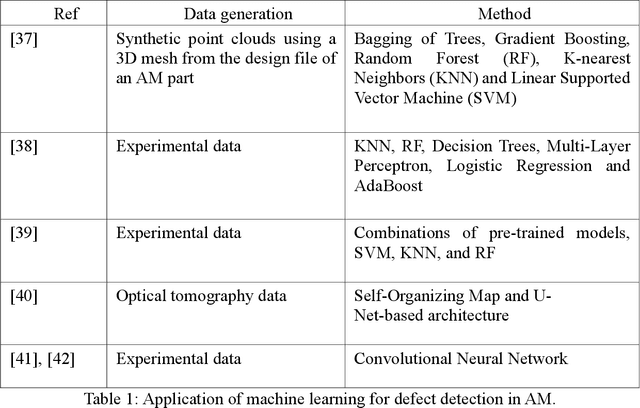

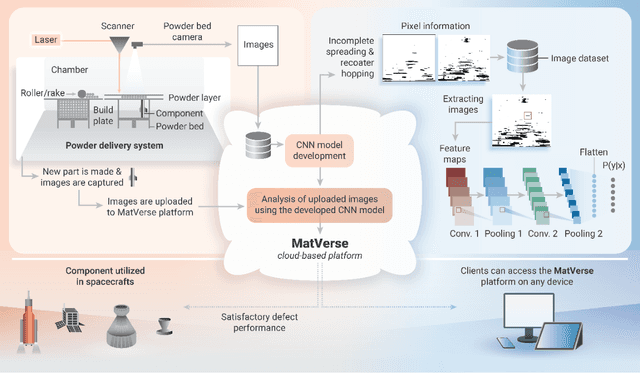

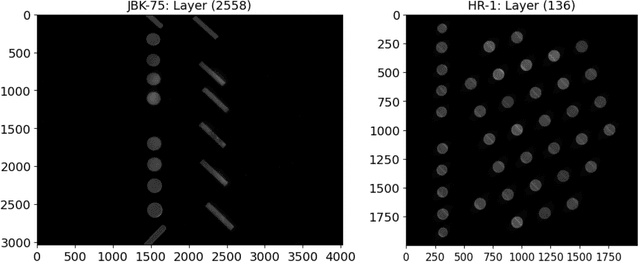

Additive Manufacturing (AM) is transforming the manufacturing sector by enabling efficient production of intricately designed products and small-batch components. However, metal parts produced via AM can include flaws that cause inferior mechanical properties, including reduced fatigue response, yield strength, and fracture toughness. To address this issue, we leverage convolutional neural networks (CNN) to analyze thermal images of printed layers, automatically identifying anomalies that impact these properties. We also investigate various synthetic data generation techniques to address limited and imbalanced AM training data. Our models' defect detection capabilities were assessed using images of Nickel alloy 718 layers produced on a laser powder bed fusion AM machine and synthetic datasets with and without added noise. Our results show significant accuracy improvements with synthetic data, emphasizing the importance of expanding training sets for reliable defect detection. Specifically, Generative Adversarial Networks (GAN)-generated datasets streamlined data preparation by eliminating human intervention while maintaining high performance, thereby enhancing defect detection capabilities. Additionally, our denoising approach effectively improves image quality, ensuring reliable defect detection. Finally, our work integrates these models in the CLoud ADditive MAnufacturing (CLADMA) module, a user-friendly interface, to enhance their accessibility and practicality for AM applications. This integration supports broader adoption and practical implementation of advanced defect detection in AM processes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge