Robust Optimal Design of Energy Efficient Series Elastic Actuators: Application to a Powered Prosthetic Ankle

Paper and Code

Feb 06, 2019

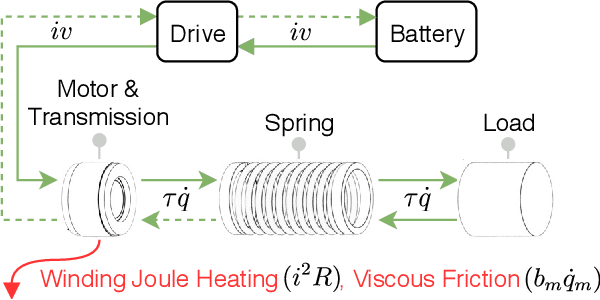

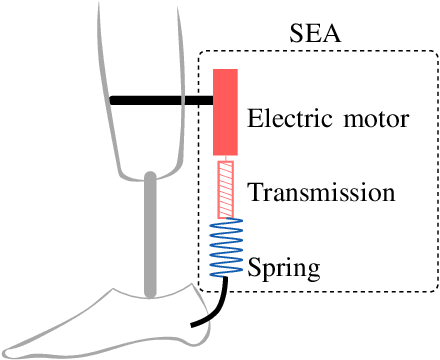

Design of robotic systems that safely and efficiently operate in uncertain operational conditions, such as rehabilitation and physical assistance robots, remains an important challenge in the field. Current methods for the design of energy efficient series elastic actuators use an optimization formulation that typically assumes known operational conditions. This approach could lead to actuators that cannot perform in uncertain environments because elongation, speed, or torque requirements may be beyond actuator specifications when the operation deviates from its nominal conditions. Addressing this gap, we propose a convex optimization formulation to design the stiffness of series elastic actuators to minimize energy consumption and satisfy actuator constraints despite uncertainty due to manufacturing of the spring, unmodeled dynamics, efficiency of the transmission, and the kinematics and kinetics of the load. In our formulation, we express energy consumption as a scalar convex-quadratic function of compliance. In the unconstrained case, this quadratic equation provides an analytical solution to the optimal value of stiffness that minimizes energy consumption for arbitrary periodic reference trajectories. As actuator constraints, we consider peak motor torque, peak motor velocity, limitations due to the speed-torque relationship of DC motors, and peak elongation of the spring. As a simulation case study, we apply our formulation to the robust design of a series elastic actuator for a powered prosthetic ankle. Our simulation results indicate that a small trade-off between energy efficiency and robustness is justified to design actuators that can operate with uncertainty.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge