Rare Class Prediction Model for Smart Industry in Semiconductor Manufacturing

Paper and Code

Jun 06, 2024

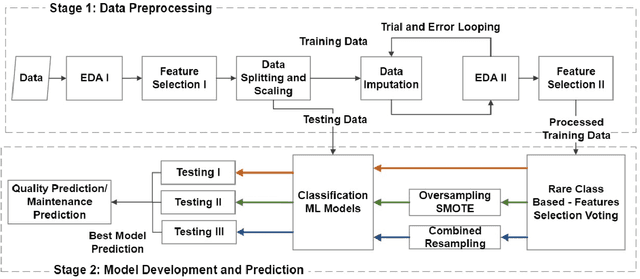

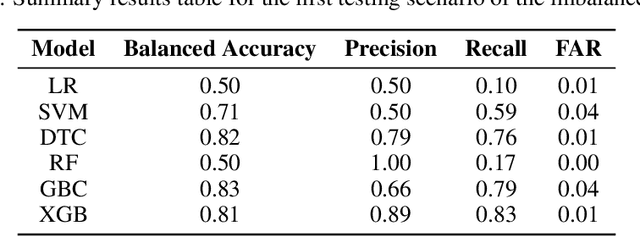

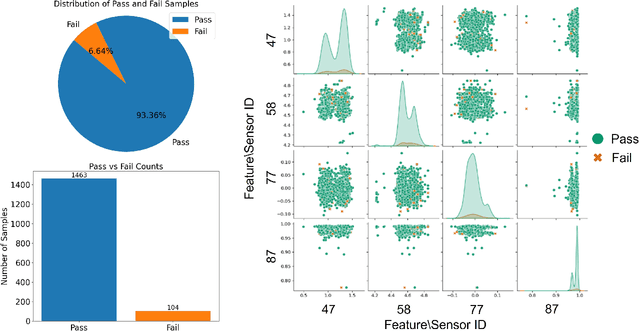

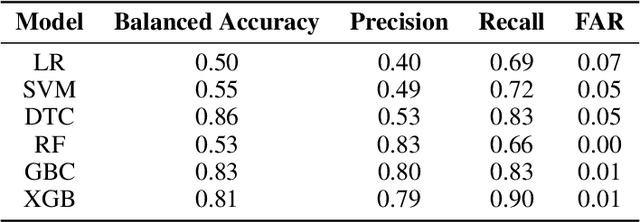

The evolution of industry has enabled the integration of physical and digital systems, facilitating the collection of extensive data on manufacturing processes. This integration provides a reliable solution for improving process quality and managing equipment health. However, data collected from real manufacturing processes often exhibit challenging properties, such as severe class imbalance, high rates of missing values, and noisy features, which hinder effective machine learning implementation. In this study, a rare class prediction approach is developed for in situ data collected from a smart semiconductor manufacturing process. The primary objective is to build a model that addresses issues of noise and class imbalance, enhancing class separation. The developed approach demonstrated promising results compared to existing literature, which would allow the prediction of new observations that could give insights into future maintenance plans and production quality. The model was evaluated using various performance metrics, with ROC curves showing an AUC of 0.95, a precision of 0.66, and a recall of 0.96

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge