Optimization-Driven Design of Monolithic Soft-Rigid Grippers

Paper and Code

Dec 10, 2024

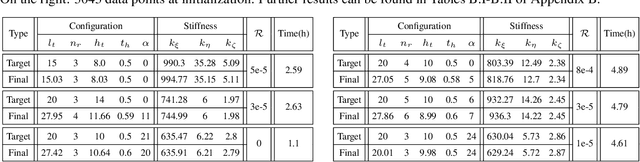

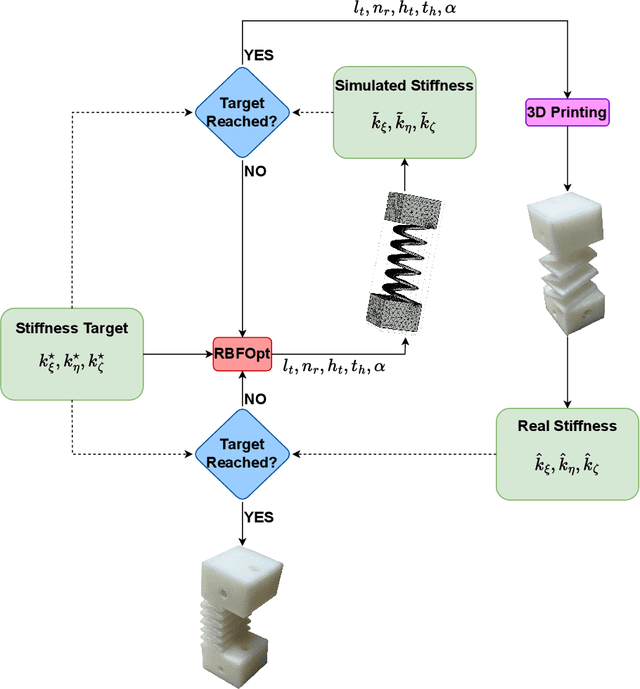

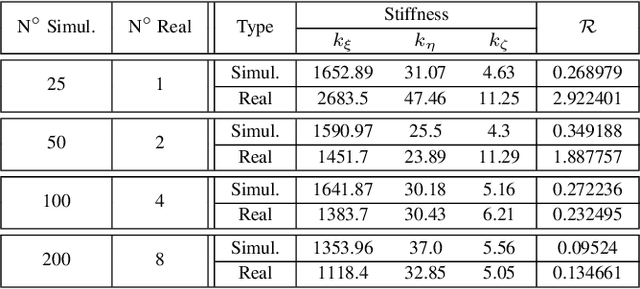

Sim-to-real transfer remains a significant challenge in soft robotics due to the unpredictability introduced by common manufacturing processes such as 3D printing and molding. These processes often result in deviations from simulated designs, requiring multiple prototypes before achieving a functional system. In this study, we propose a novel methodology to address these limitations by combining advanced rapid prototyping techniques and an efficient optimization strategy. Firstly, we employ rapid prototyping methods typically used for rigid structures, leveraging their precision to fabricate compliant components with reduced manufacturing errors. Secondly, our optimization framework minimizes the need for extensive prototyping, significantly reducing the iterative design process. The methodology enables the identification of stiffness parameters that are more practical and achievable within current manufacturing capabilities. The proposed approach demonstrates a substantial improvement in the efficiency of prototype development while maintaining the desired performance characteristics. This work represents a step forward in bridging the sim-to-real gap in soft robotics, paving the way towards a faster and more reliable deployment of soft robotic systems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge