Multi-purpose robot for rehabilitation of small diameter water pipes

Paper and Code

May 23, 2024

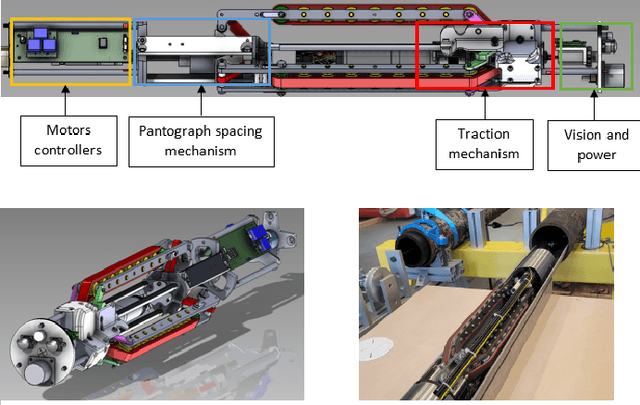

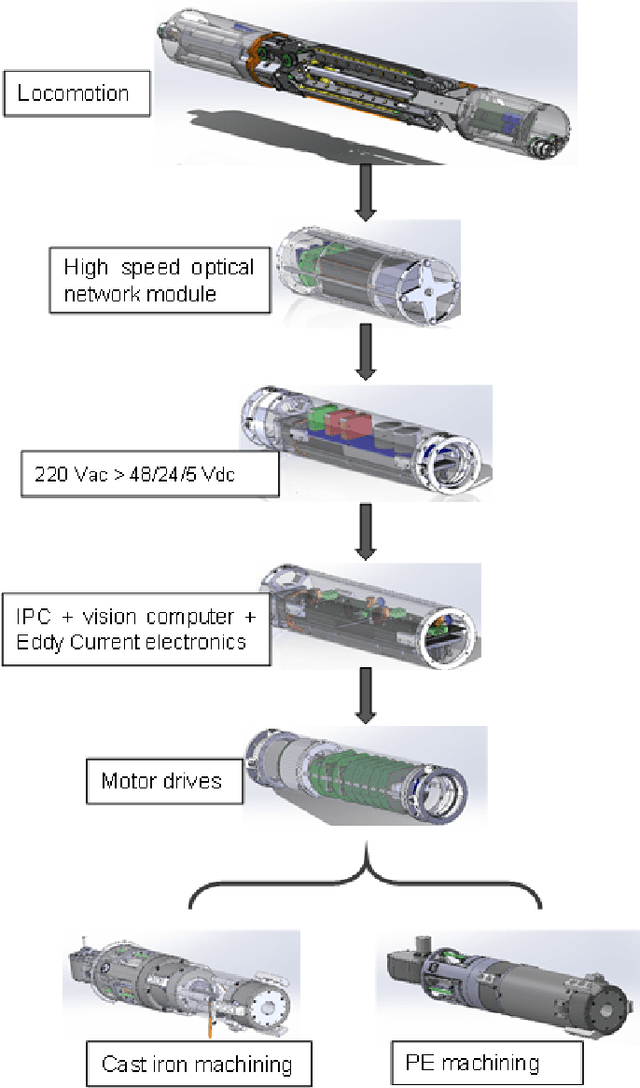

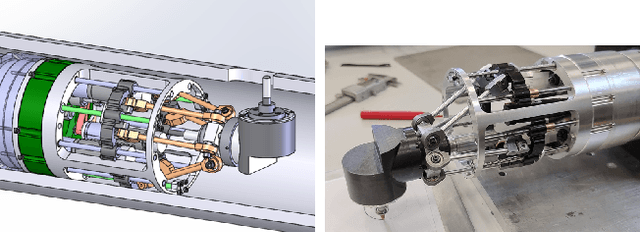

Rehabilitating cast iron pipes through lining offers several advantages, including increased durability, reduced water leaks, and minimal disruption.This approach presents a cost effective and environmentally friendly solution by sealing cracks and joints, extending the pipeline's lifespan, and reducing water wastage, all while avoiding the need for trench excavation. However, due to the relining process, branch connections are sealed and need to be reestablished. To address the issue of rehabilitating small-diameter water pipes, we have designed a modular robot capable of traversing and working within 200 meter long, 100 mm diameter cast iron pipes. This robot is equipped with perception functions to detect, locate, and characterize the branch connections in cast iron pipes and relocate them after lining, as well as machining functions. A first prototype of this system has been developed and validated on an 8 meter long section, in a laboratory environment.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge