Inverse Kinematics and Sensitivity Minimization of an n-Stack Stewart Platform

Paper and Code

Nov 13, 2018

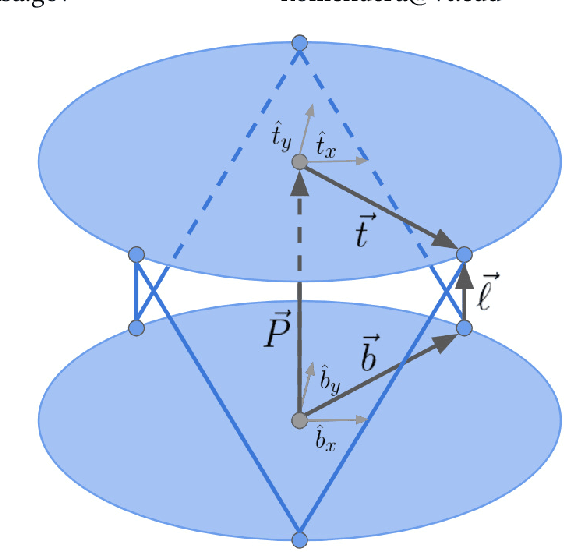

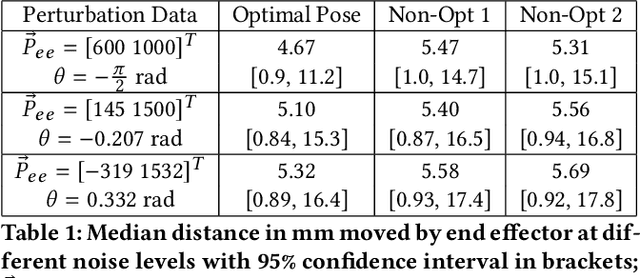

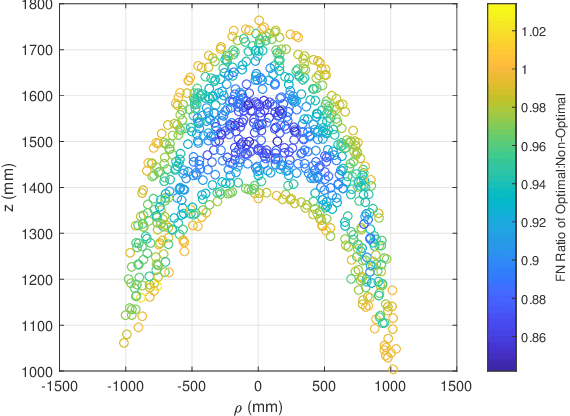

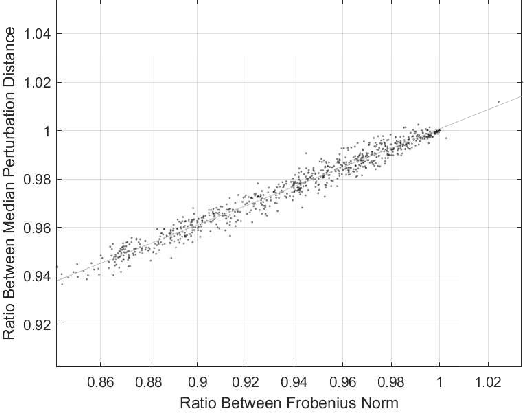

An autonomous system is presented to solve the problem of in space assembly, which can be used to further the NASA goal of deep space exploration. Of particular interest is the assembly of large truss structures, which requires precise and dexterous movement in a changing environment. A prototype of an autonomous manipulator called "Assemblers" was fabricated from an aggregation of Stewart Platform robots for the purpose of researching autonomous in space assembly capabilities. The forward kinematics for an Assembler is described by the set of translations and rotation angles for each component Stewart Platform, from which the position and orientation of the end effector are simple to calculate. However, selecting inverse kinematic poses, defined by the translations and rotation angles, for the Assembler requires coordination between each Stewart Platform and is an underconstrained non-linear optimization problem. For assembly tasks, it is ideal that the pose selected has the least sensitivity to disturbances possible. A method of sensitivity reduction is proposed by minimizing the Frobenius Norm (FN) of the Jacobian for the forward kinematics. The effectiveness of the FN method will be demonstrated through a Monte Carlo simulation method to model random motion internal to the structure.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge