Inspector Gadget: A Data Programming-based Labeling System for Industrial Images

Paper and Code

Apr 07, 2020

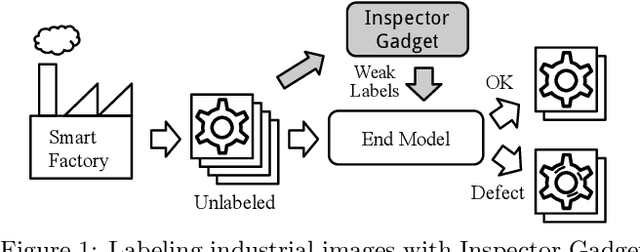

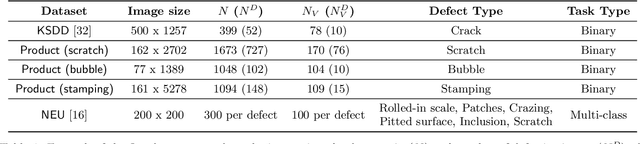

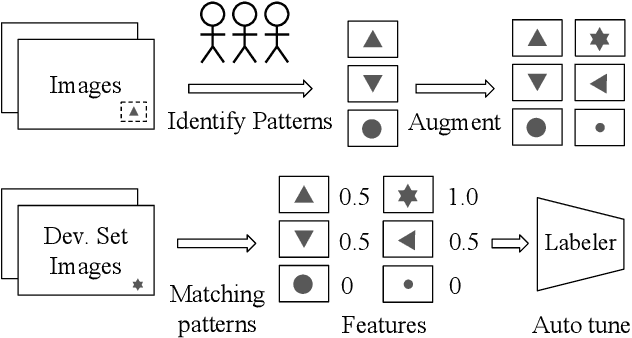

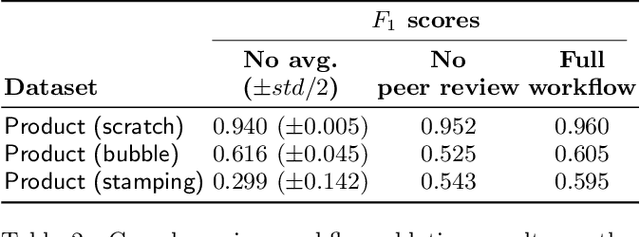

As machine learning for images becomes democratized in the Software 2.0 era, one of the serious bottlenecks is securing enough labeled data for training. This problem is especially critical in a manufacturing setting where smart factories rely on machine learning for product quality control by analyzing industrial images. Such images are typically large and may only need to be partially analyzed where only a small portion is problematic (e.g., identifying defects on a surface). Since manual labeling these images is expensive, weak supervision is an attractive alternative where the idea is to generate weak labels that are not perfect, but can be produced at scale. Data programming is a recent paradigm in this category where it uses human knowledge in the form of labeling functions and combines them into a generative model. Data programming has been successful in applications based on text or structured data and can also be applied to images usually if one can find a way to convert them into structured data. In this work, we expand the horizon of data programming by directly applying it to images without this conversion, which is a common scenario for industrial applications. We propose Inspector Gadget, an image labeling system that combines crowdsourcing, data augmentation, and data programming to produce weak labels at scale for image classification. We perform experiments on real industrial image datasets and show that Inspector Gadget obtains better accuracy than state-of-the-art techniques: Snuba, GOGGLES, and self-learning baselines using convolutional neural networks (CNNs) without pre-training.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge