In-Hand Pose Estimation and Pin Inspection for Insertion of Through-Hole Components

Paper and Code

Aug 02, 2022

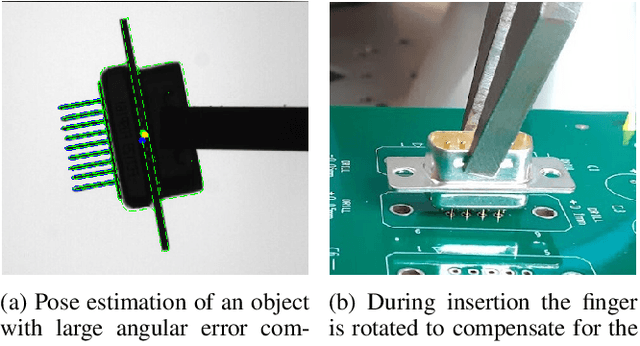

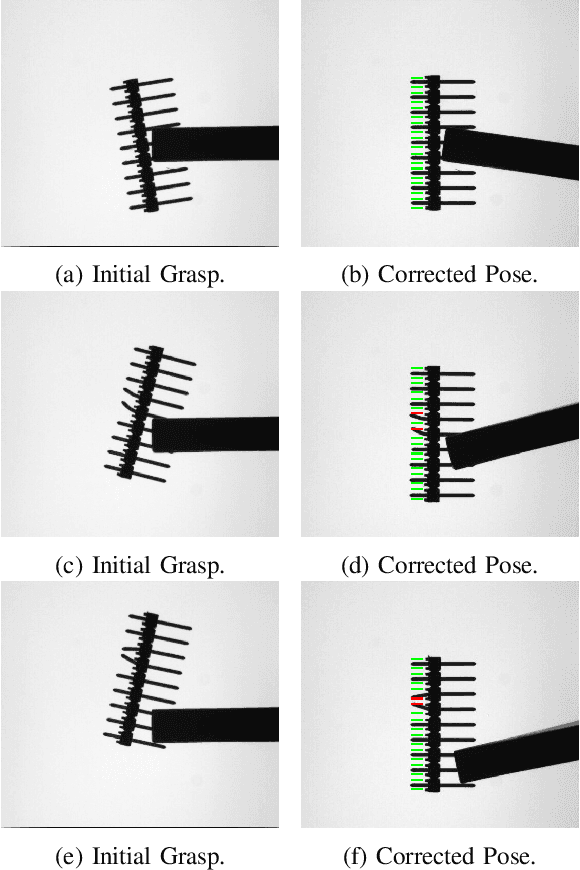

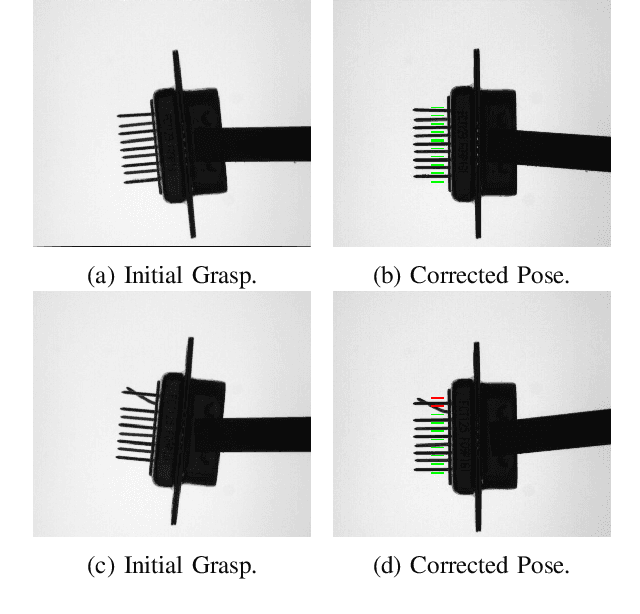

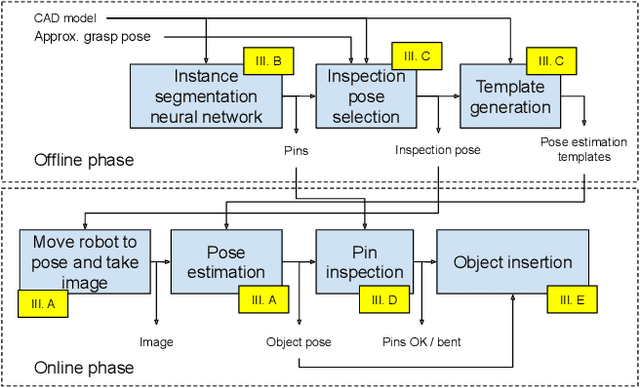

The insertion of through-hole components is a difficult task. As the tolerances of the holes are very small, minor errors in the insertion will result in failures. These failures can damage components and will require manual intervention for recovery. Errors can occur both from imprecise object grasps and bent pins. Therefore, it is important that a system can accurately determine the object's position and reject components with bent pins. By utilizing the constraints inherent in the object grasp a method using template matching is able to obtain very precise pose estimates. Methods for pin-checking are also implemented, compared, and a successful method is shown. The set-up is performed automatically, with two novel contributions. A deep learning segmentation of the pins is performed and the inspection pose is found by simulation. From the inspection pose and the segmented pins, the templates for pose estimation and pin check are then generated. To train the deep learning method a dataset of segmented through-hole components is created. The network shows a 97.3 % accuracy on the test set. The pin-segmentation network is also tested on the insertion CAD models and successfully segment the pins. The complete system is tested on three different objects, and experiments show that the system is able to insert all objects successfully. Both by correcting in-hand grasp errors and rejecting objects with bent pins.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge