Hybrid full-field thermal characterization of additive manufacturing processes using physics-informed neural networks with data

Paper and Code

Jun 15, 2022

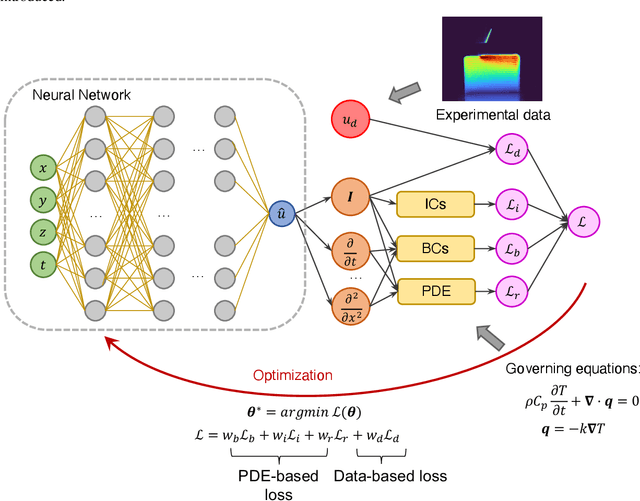

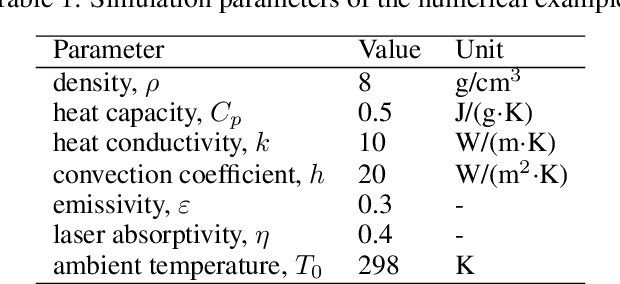

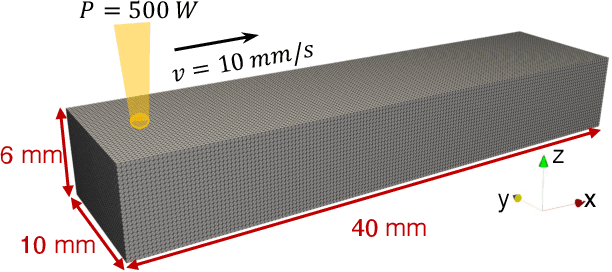

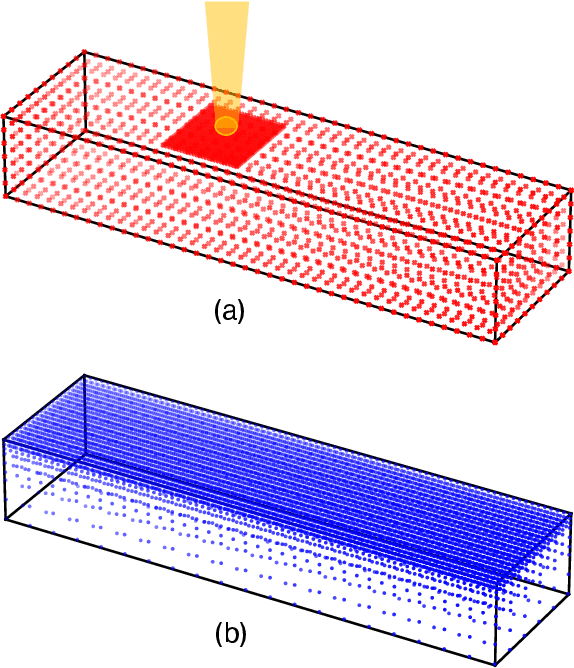

Understanding the thermal behavior of additive manufacturing (AM) processes is crucial for enhancing the quality control and enabling customized process design. Most purely physics-based computational models suffer from intensive computational costs, thus not suitable for online control and iterative design application. Data-driven models taking advantage of the latest developed computational tools can serve as a more efficient surrogate, but they are usually trained over a large amount of simulation data and often fail to effectively use small but high-quality experimental data. In this work, we developed a hybrid physics-based data-driven thermal modeling approach of AM processes using physics-informed neural networks. Specifically, partially observed temperature data measured from an infrared camera is combined with the physics laws to predict full-field temperature history and to discover unknown material and process parameters. In the numerical and experimental examples, the effectiveness of adding auxiliary training data and using the technique of transfer learning on training efficiency and prediction accuracy, as well as the ability to identify unknown parameters with partially observed data, are demonstrated. The results show that the hybrid thermal model can effectively identify unknown parameters and capture the full-field temperature accurately, and thus it has the potential to be used in iterative process design and real-time process control of AM.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge