Feature anomaly detection system (FADS) for intelligent manufacturing

Paper and Code

Apr 21, 2022

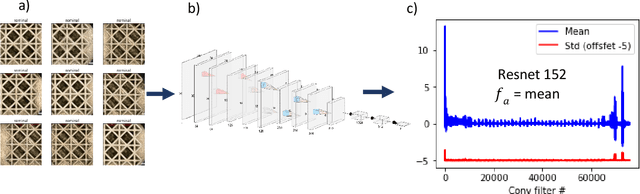

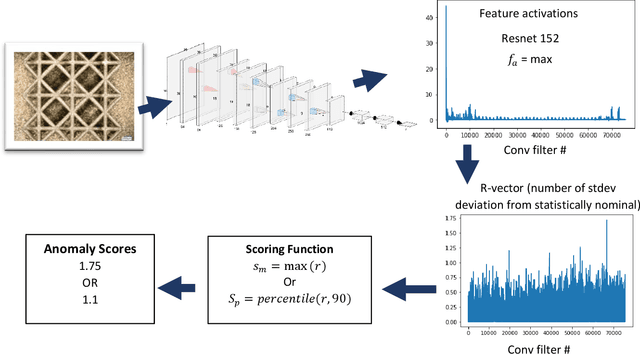

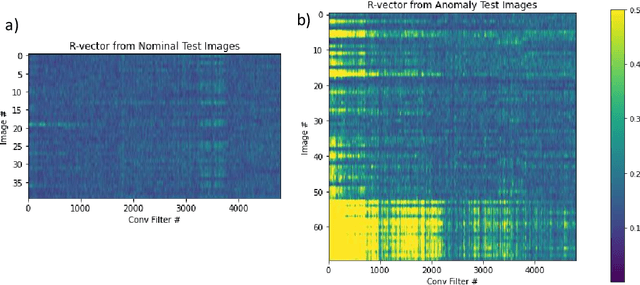

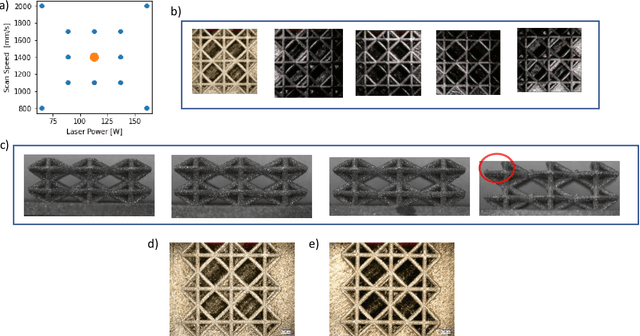

Anomaly detection is important for industrial automation and part quality assurance, and while humans can easily detect anomalies in components given a few examples, designing a generic automated system that can perform at human or above human capabilities remains a challenge. In this work, we present a simple new anomaly detection algorithm called FADS (feature-based anomaly detection system) which leverages pretrained convolutional neural networks (CNN) to generate a statistical model of nominal inputs by observing the activation of the convolutional filters. During inference the system compares the convolutional filter activation of the new input to the statistical model and flags activations that are outside the expected range of values and therefore likely an anomaly. By using a pretrained network, FADS demonstrates excellent performance similar to or better than other machine learning approaches to anomaly detection while at the same time FADS requires no tuning of the CNN weights. We demonstrate FADS ability by detecting process parameter changes on a custom dataset of additively manufactured lattices. The FADS localization algorithm shows that textural differences that are visible on the surface can be used to detect process parameter changes. In addition, we test FADS on benchmark datasets, such as the MVTec Anomaly Detection dataset, and report good results.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge