False Data Injection Attacks in Internet of Things and Deep Learning enabled Predictive Analytics

Paper and Code

Oct 03, 2019

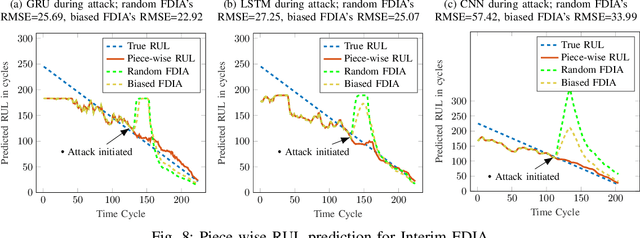

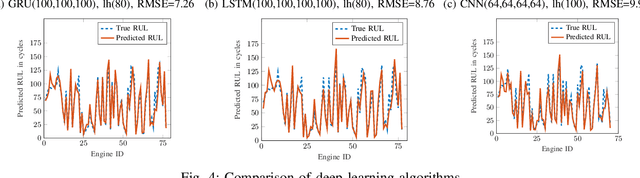

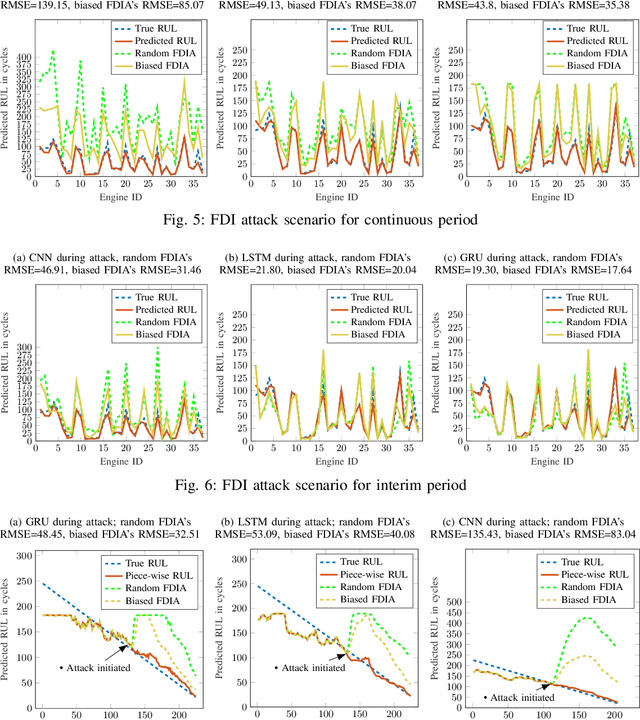

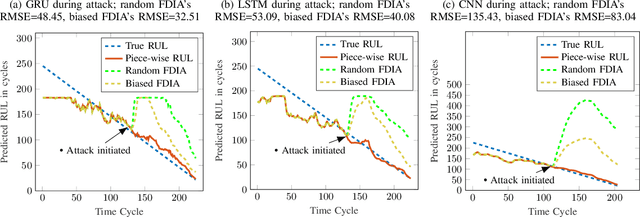

Industry 4.0 is the latest industrial revolution primarily merging automation with advanced manufacturing to reduce human effort and resources. Predictive maintenance (PdM) is an industry 4.0 solution, which facilitates predicting faults in a component or a system powered by state-of-the-art machine learning (ML) algorithms (especially deep learning) and the Internet-of-Things (IoT) sensors. However, IoT sensors and deep learning (DL) algorithms, both are known for their vulnerabilities to cyber-attacks. In the context of PdM systems, such attacks can have catastrophic consequences as they are hard to detect. To date, the majority of the published literature focuses on the accuracy of the IoT and DL enabled PdM systems and often ignores the effect of such attacks. In this paper, we demonstrate the effect of IoT sensor attacks (in the form of false data injection attack) on a PdM system. At first, we use three state-of-the-art DL algorithms, specifically, Long Short-Term Memory (LSTM), Gated Recurrent Unit (GRU), and Convolutional Neural Network (CNN) for predicting the Remaining Useful Life (RUL) of a turbofan engine using NASA's C-MAPSS dataset. Our obtained results show that the GRU-based PdM model outperforms some of the recent literature on RUL prediction using the C-MAPSS dataset. Afterward, we model and apply two different types of false data injection attacks (FDIA) on turbofan engine sensor data and evaluate their impact on CNN, LSTM, and GRU-based PdM systems. Our results demonstrate that attacks on even a small number of IoT sensors can strongly defect the RUL prediction. However, the GRU-based PdM model performs better in terms of accuracy and resiliency. Lastly, we perform a study on the GRU-based PdM model using four different GRU networks. Our experiments reveal an interesting relationship between the accuracy, resiliency and sequence length for the GRU-based PdM models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge