Explainable Artificial Intelligence for Manufacturing Cost Estimation and Machining Feature Visualization

Paper and Code

Oct 28, 2020

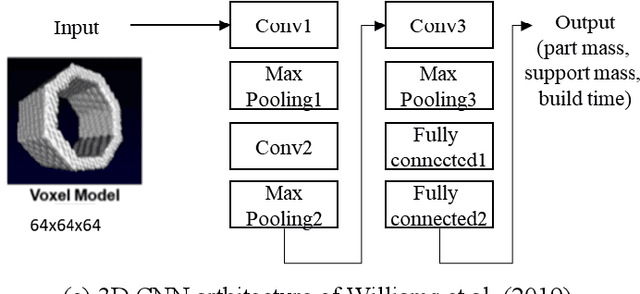

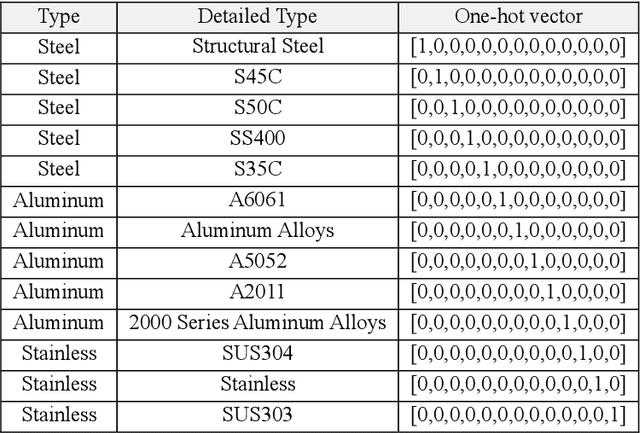

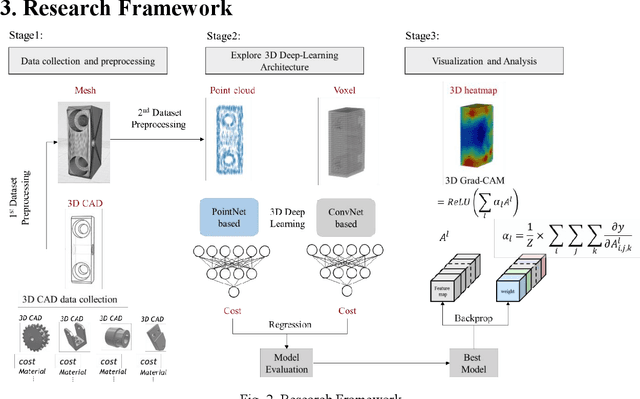

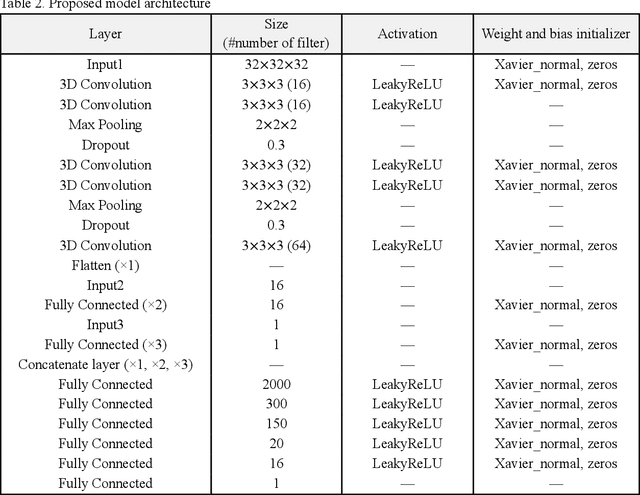

Studies on manufacturing cost prediction based on deep learning have begun in recent years, but the cost prediction rationale cannot be explained because the models are still used as a black box. This study aims to propose a manufacturing cost prediction process for 3D computer-aided design (CAD) models using explainable artificial intelligence. The proposed process can visualize the machining features of the 3D CAD model that are influencing the increase in manufacturing costs. The proposed process consists of (1) data collection and pre-processing, (2) 3D deep learning architecture exploration, and (3) visualization to explain the prediction results. The proposed deep learning model shows high predictability of manufacturing cost for the computer numerical control (CNC) machined parts. In particular, using 3D gradient-weighted class activation mapping proves that the proposed model not only can detect the CNC machining features but also can differentiate the machining difficulty for the same feature. Using the proposed process, we can provide a design guidance to engineering designers in reducing manufacturing costs during the conceptual design phase. We can also provide real-time quotations and redesign proposals to online manufacturing platform customers.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge