Development and Testing of a Smart Bin toward Automated Rearing of Black Soldier Fly Larvae

Paper and Code

Jul 09, 2022

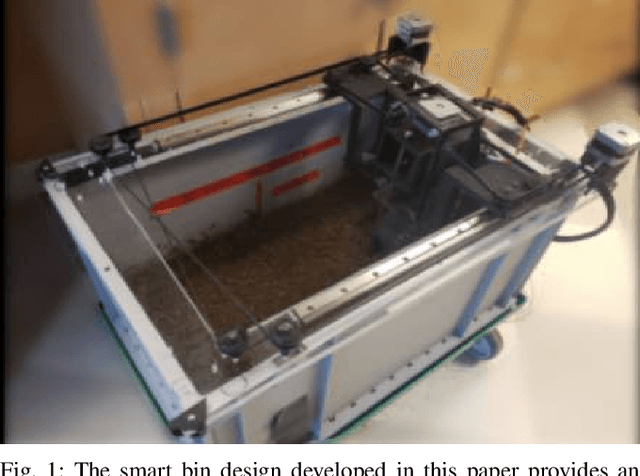

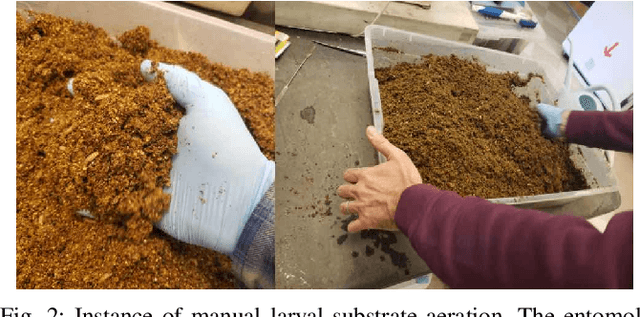

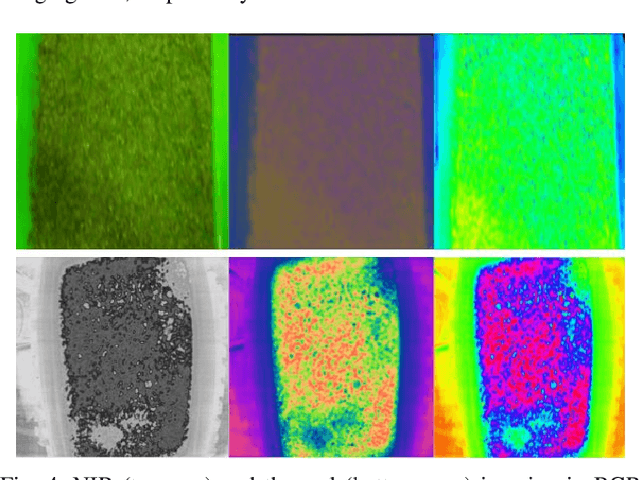

The Black Soldier Fly (BSF), can be an effective alternative to traditional disposal of food and agricultural waste (biowaste) such as landfills because its larvae are able to quickly transform biowaste into ready-to-use biomass. However, several challenges remain to ensure that BSF farming is economically viable at different scales and can be widely implemented. Manual labor is required to ensure optimal conditions to rear the larvae, from aerating the feeding substrate to monitoring abiotic conditions during the growth cycle. This paper introduces a proof-of-concept automated method of rearing BSF larvae to ensure optimal growing conditions while at the same time reducing manual labor. We retrofit existing BSF rearing bins with a "smart lid," named as such due to the hot-swappable nature of the lid with multiple bins. The system automatically aerates the larvae-diet substrate and provides bio-information of the larvae to users in real time. The proposed solution uses a custom aeration method and an array of sensors to create a soft real time system. Growth of larvae is monitored using thermal imaging and classical computer vision techniques. Experimental testing reveals that our automated approach produces BSF larvae on par with manual techniques.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge