DETECTA 2.0: Research into non-intrusive methodologies supported by Industry 4.0 enabling technologies for predictive and cyber-secure maintenance in SMEs

Paper and Code

May 24, 2024

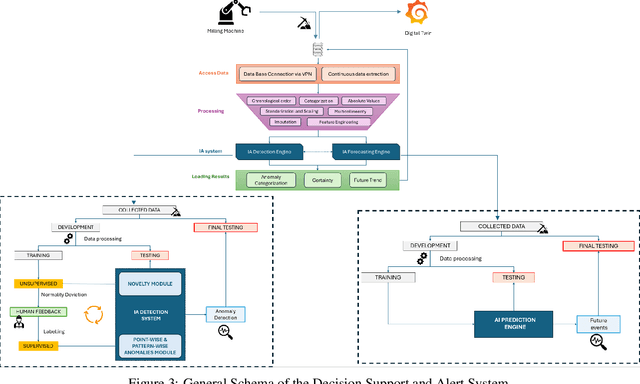

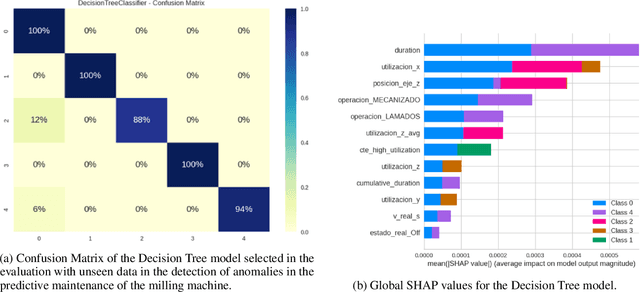

The integration of predictive maintenance and cybersecurity represents a transformative advancement for small and medium-sized enterprises (SMEs) operating within the Industry 4.0 paradigm. Despite their economic importance, SMEs often face significant challenges in adopting advanced technologies due to resource constraints and knowledge gaps. The DETECTA 2.0 project addresses these hurdles by developing an innovative system that harmonizes real-time anomaly detection, sophisticated analytics, and predictive forecasting capabilities. The system employs a semi-supervised methodology, combining unsupervised anomaly detection with supervised learning techniques. This approach enables more agile and cost-effective development of AI detection systems, significantly reducing the time required for manual case review. At the core lies a Digital Twin interface, providing intuitive real-time visualizations of machine states and detected anomalies. Leveraging cutting-edge AI engines, the system intelligently categorizes anomalies based on observed patterns, differentiating between technical errors and potential cybersecurity incidents. This discernment is fortified by detailed analytics, including certainty levels that enhance alert reliability and minimize false positives. The predictive engine uses advanced time series algorithms like N-HiTS to forecast future machine utilization trends. This proactive approach optimizes maintenance planning, enhances cybersecurity measures, and minimizes unplanned downtimes despite variable production processes. With its modular architecture enabling seamless integration across industrial setups and low implementation costs, DETECTA 2.0 presents an attractive solution for SMEs to strengthen their predictive maintenance and cybersecurity strategies.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge