Customizing Pareto Simulated Annealing for Multi-objective Optimization of Control Cabinet Layout

Paper and Code

Jun 04, 2019

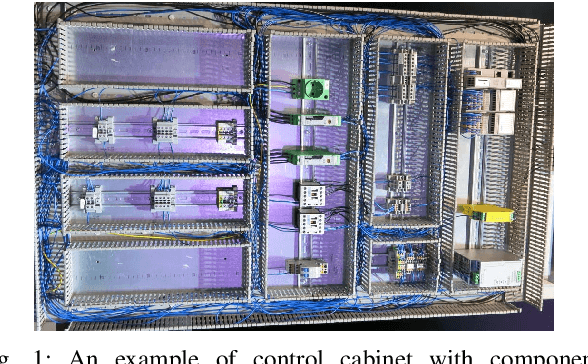

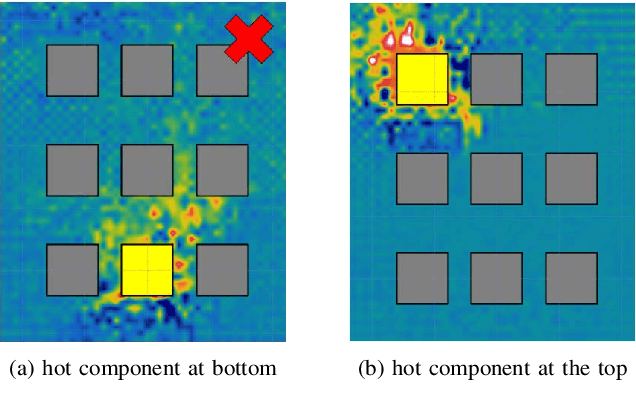

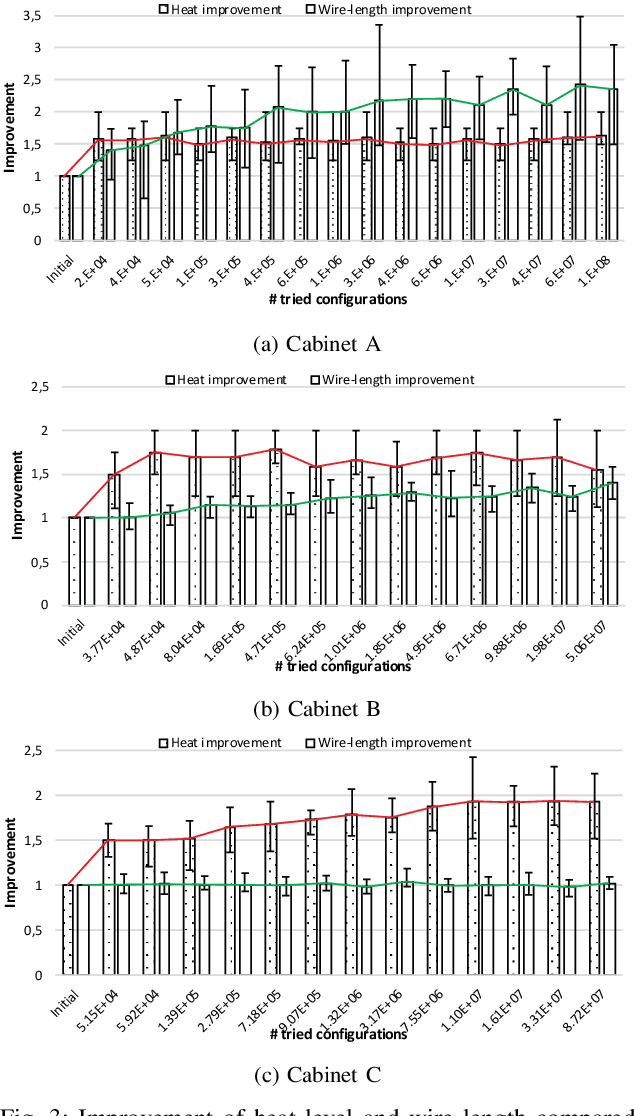

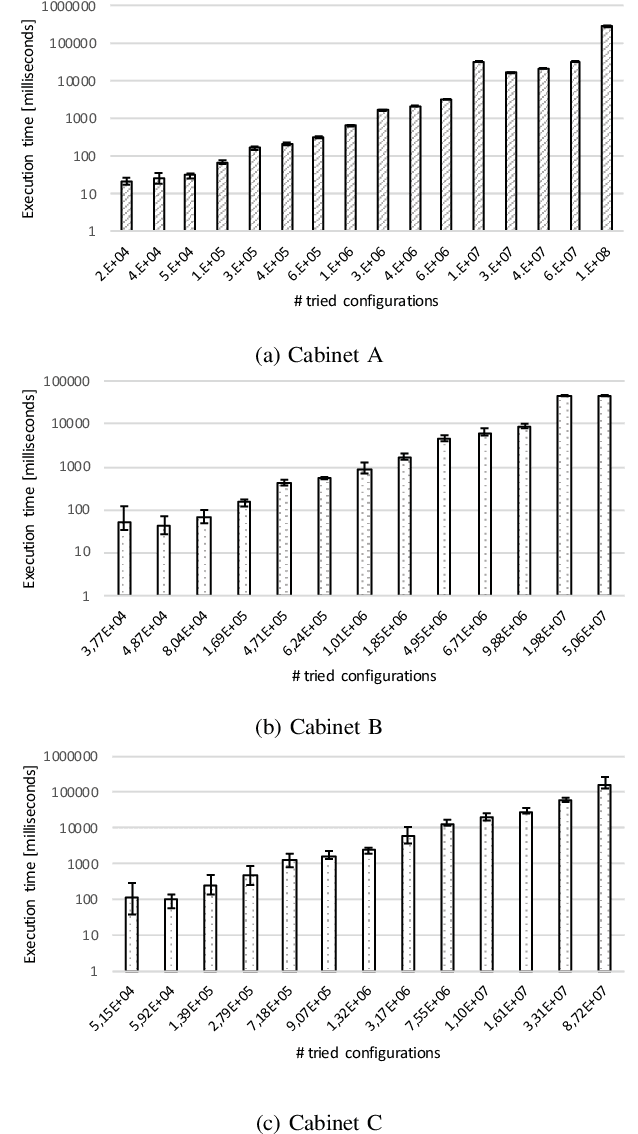

Determining the optimal location of control cabinet components requires the exploration of a large configuration space. For real-world control cabinets it is impractical to evaluate all possible cabinet configurations. Therefore, we need to apply methods for intelligent exploration of cabinet configuration space that enable to find a near-optimal configuration without evaluation of all possible configurations. In this paper, we describe an approach for multi-objective optimization of control cabinet layout that is based on Pareto Simulated Annealing. Optimization aims at minimizing the total wire length used for interconnection of components and the heat convection within the cabinet. We simulate heat convection to study the warm air flow within the control cabinet and determine the optimal position of components that generate heat during the operation. We evaluate and demonstrate the effectiveness of our approach empirically for various control cabinet sizes and usage scenarios.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge