Control and Navigation Framework for a Hybrid Steel Bridge Inspection Robot

Paper and Code

Feb 01, 2021

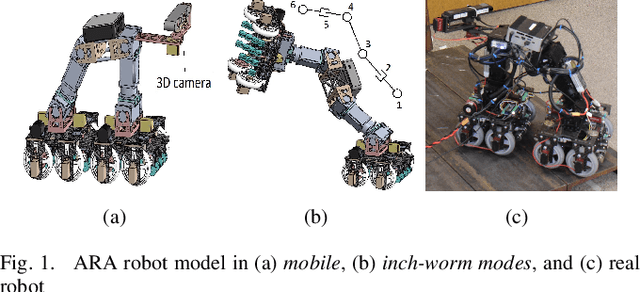

Autonomous navigation of steel bridge inspection robots is essential for proper maintenance. The majority of existing robotic solutions for steel bridge inspection requires human intervention to assist in the control and navigation. In this paper, a control and navigation framework has been proposed for the steel bridge inspection robot developed by the Advanced Robotics and Automation (ARA)to facilitate autonomous real-time navigation and minimize human intervention. The ARA robot is designed to work in two modes: mobile and inch-worm. The robot uses mobile mode when moving on a plane surface and inch-worm mode when jumping from one surface to the other. To allow the ARA robot to switch between mobile and inch-worm modes, a switching controller is developed with 3D point cloud data based. The surface detection algorithm is proposed to allow the robot to check the availability of steel surfaces (plane, area, and height) to determine the transformation from mobile mode to inch-worm one. To have the robot safely navigate and visit all steel members of the bridge, four algorithms are developed to process the data from a depth camera, segment it into clusters, estimate the boundaries, construct a graph representing the structure, generate the shortest inspection path with any starting and ending points, and determine available robot configuration for path planning. Experiments on steel bridge structures setup highlight the effective performance of the algorithms, and the potential to apply to the ARA robot to run on real bridge structures.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge