Assembly of randomly placed parts realized by using only one robot arm with a general parallel-jaw gripper

Paper and Code

Sep 19, 2019

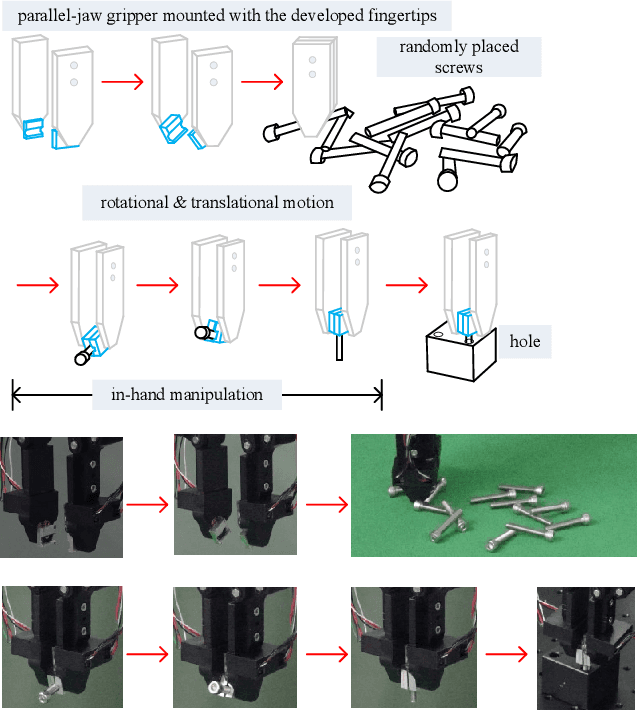

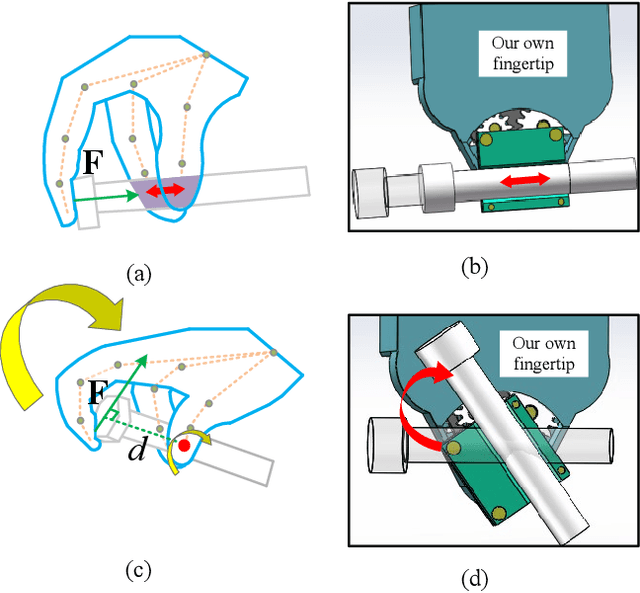

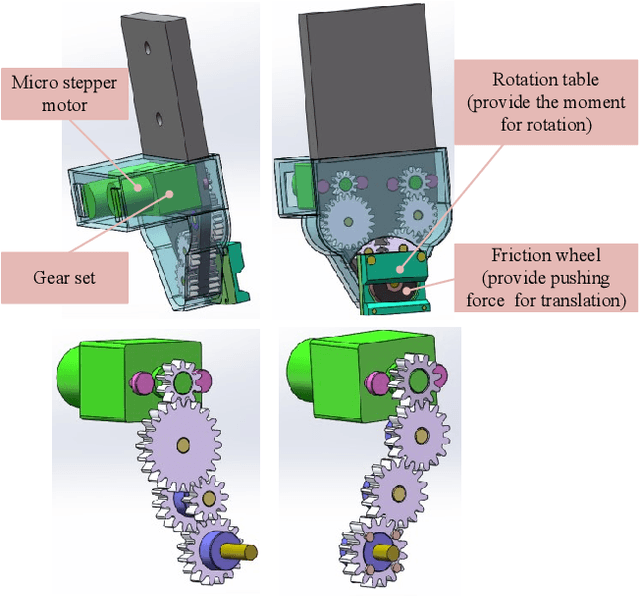

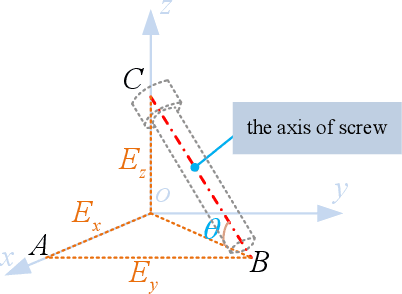

In industry assembly lines, parts feeding machines are widely employed as the prologue of the whole procedure. They play the role of sorting the parts randomly placed in bins to the state with specified pose. With the help of the parts feeding machines, the subsequent assembly processes by robot arm can always start from the same condition. Thus it is expected that function of parting feeding machine and the robotic assembly can be integrated with one robot arm. This scheme can provide great flexibility and can also contribute to reduce the cost. The difficulties involved in this scheme lie in the fact that in the part feeding phase, the pose of the part after grasping may be not proper for the subsequent assembly. Sometimes it can not even guarantee a stable grasp. In this paper, we proposed a method to integrate parts feeding and assembly within one robot arm. This proposal utilizes a specially designed gripper tip mounted on the jaws of a two-fingered gripper. With the modified gripper, in-hand manipulation of the grasped object is realized, which can ensure the control of the orientation and offset position of the grasped object. The proposal in this paper is verified by a simulated assembly in which a robot arm completed the assembly process including parts picking from bin and a subsequent peg-in-hole assembly.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge