An Experimentally Driven Automated Machine Learned lnter-Atomic Potential for a Refractory Oxide

Paper and Code

Sep 09, 2020

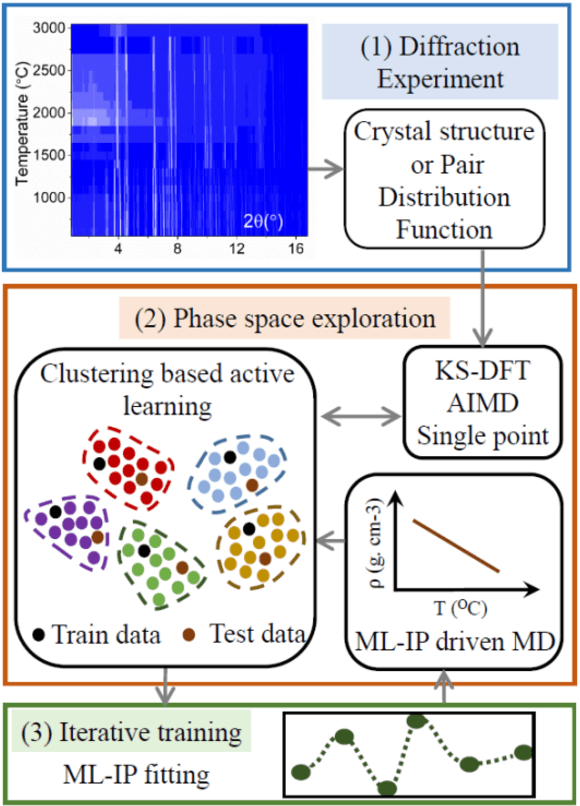

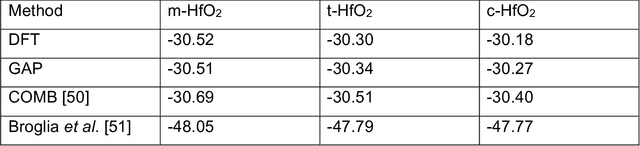

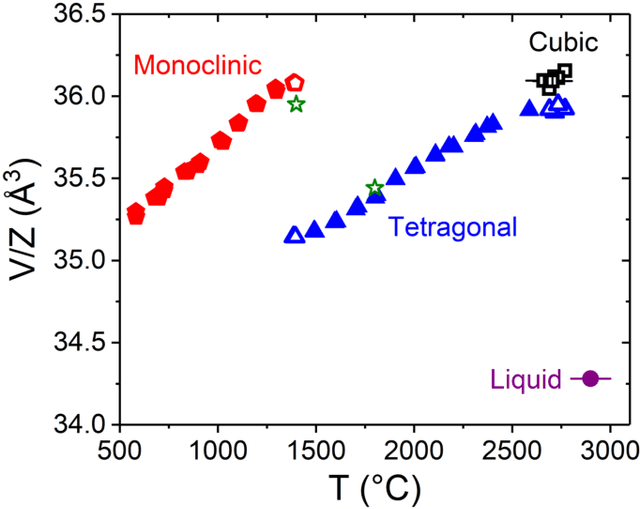

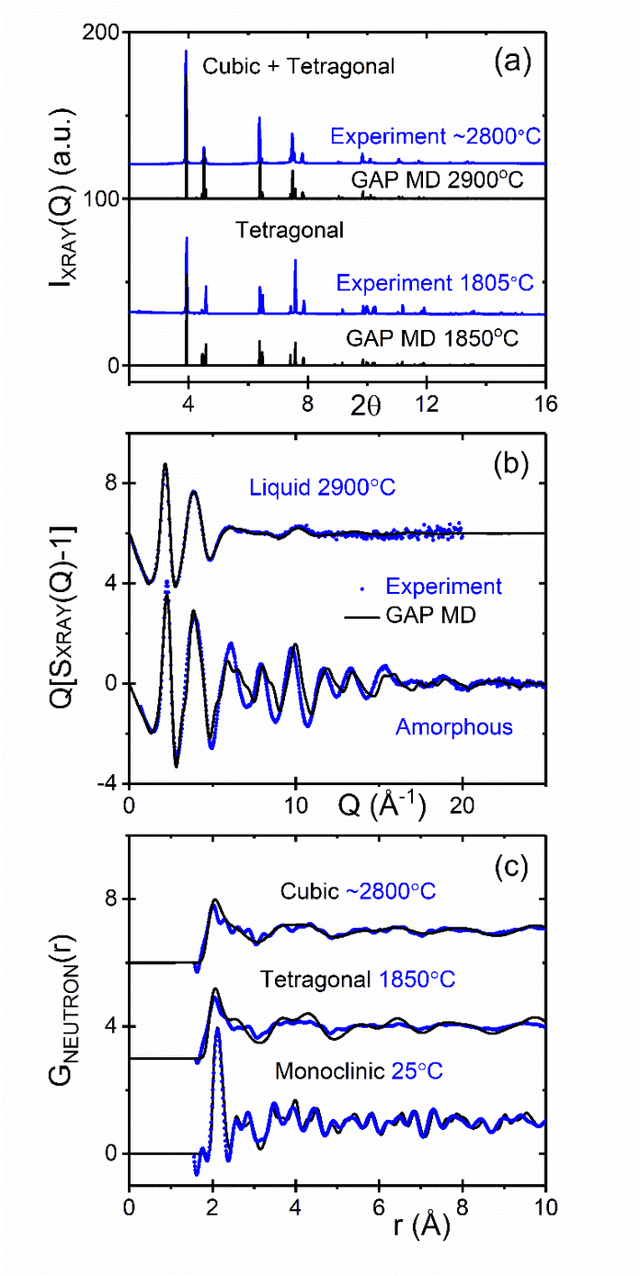

Understanding the structure and properties of refractory oxides are critical for high temperature applications. In this work, a combined experimental and simulation approach uses an automated closed loop via an active-learner, which is initialized by X-ray and neutron diffraction measurements, and sequentially improves a machine-learning model until the experimentally predetermined phase space is covered. A multi-phase potential is generated for a canonical example of the archetypal refractory oxide, HfO2, by drawing a minimum number of training configurations from room temperature to the liquid state at ~2900oC. The method significantly reduces model development time and human effort.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge