Active learning using weakly supervised signals for quality inspection

Paper and Code

Apr 07, 2021

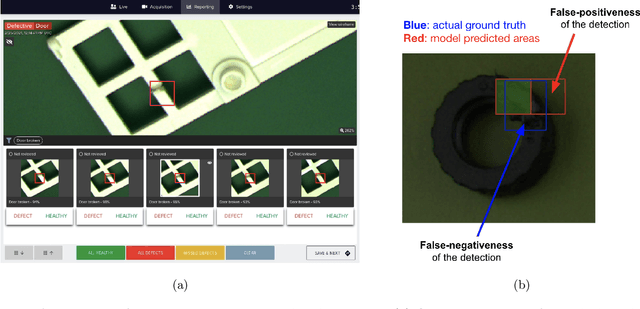

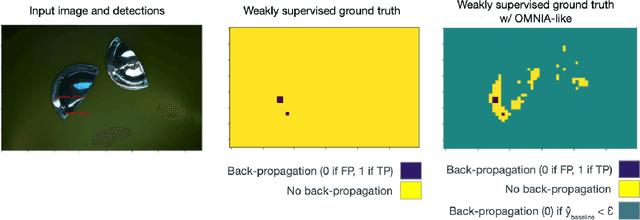

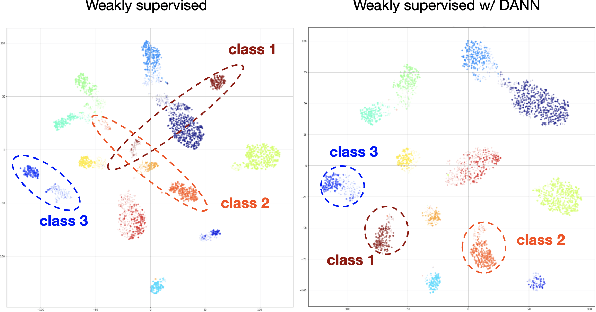

Because manufacturing processes evolve fast, and since production visual aspect can vary significantly on a daily basis, the ability to rapidly update machine vision based inspection systems is paramount. Unfortunately, supervised learning of convolutional neural networks requires a significant amount of annotated images for being able to learn effectively from new data. Acknowledging the abundance of continuously generated images coming from the production line and the cost of their annotation, we demonstrate it is possible to prioritize and accelerate the annotation process. In this work, we develop a methodology for learning actively, from rapidly mined, weakly (i.e. partially) annotated data, enabling a fast, direct feedback from the operators on the production line and tackling a big machine vision weakness: false positives. We also consider the problem of covariate shift, which arises inevitably due to changing conditions during data acquisition. In that regard, we show domain-adversarial training to be an efficient way to address this issue.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge