A Probabilistic Model For Sensor Validation

Paper and Code

Feb 13, 2013

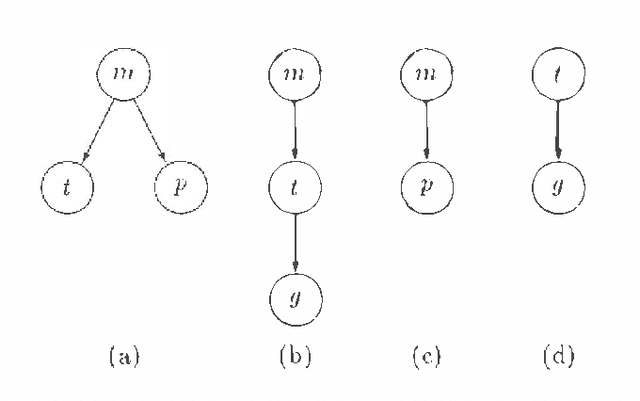

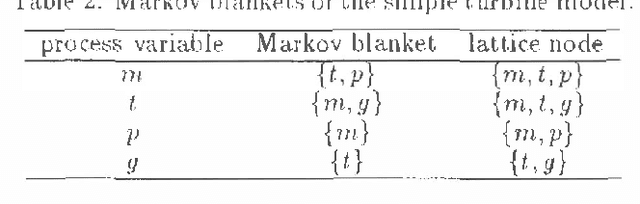

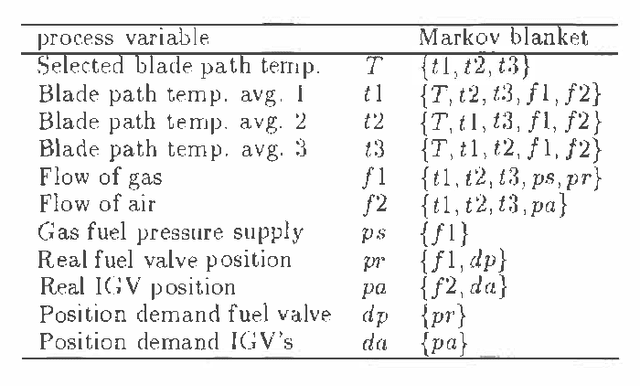

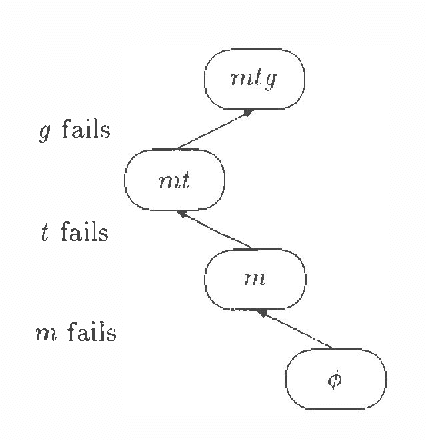

The validation of data from sensors has become an important issue in the operation and control of modern industrial plants. One approach is to use knowledge based techniques to detect inconsistencies in measured data. This article presents a probabilistic model for the detection of such inconsistencies. Based on probability propagation, this method is able to find the existence of a possible fault among the set of sensors. That is, if an error exists, many sensors present an apparent fault due to the propagation from the sensor(s) with a real fault. So the fault detection mechanism can only tell if a sensor has a potential fault, but it can not tell if the fault is real or apparent. So the central problem is to develop a theory, and then an algorithm, for distinguishing real and apparent faults, given that one or more sensors can fail at the same time. This article then, presents an approach based on two levels: (i) probabilistic reasoning, to detect a potential fault, and (ii) constraint management, to distinguish the real fault from the apparent ones. The proposed approach is exemplified by applying it to a power plant model.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge