A Priori Calibration of Transient Kinetics Data via Machine Learning

Paper and Code

Sep 27, 2021

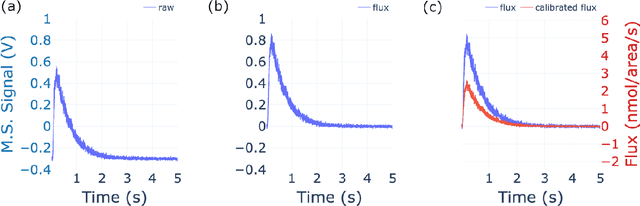

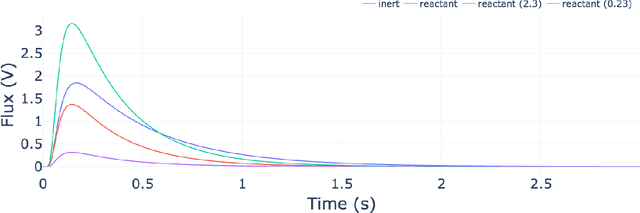

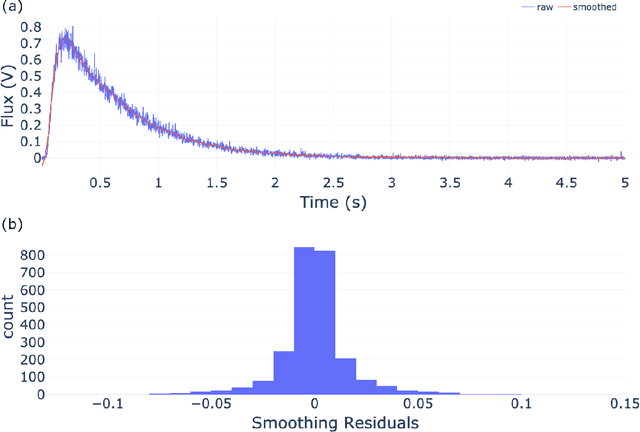

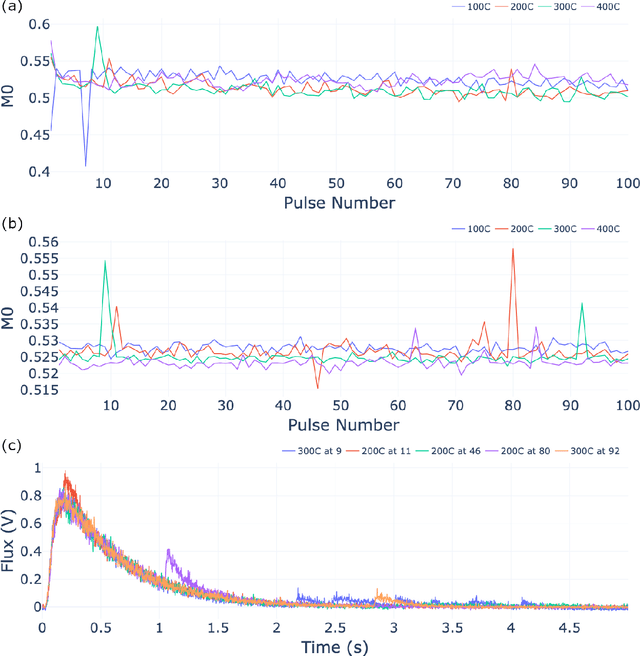

The temporal analysis of products reactor provides a vast amount of transient kinetic information that may be used to describe a variety of chemical features including the residence time distribution, kinetic coefficients, number of active sites, and the reaction mechanism. However, as with any measurement device, the TAP reactor signal is convoluted with noise. To reduce the uncertainty of the kinetic measurement and any derived parameters or mechanisms, proper preprocessing must be performed prior to any advanced analysis. This preprocessing consists of baseline correction, i.e., a shift in the voltage response, and calibration, i.e., a scaling of the flux response based on prior experiments. The current methodology of preprocessing requires significant user discretion and reliance on previous experiments that may drift over time. Herein we use machine learning techniques combined with physical constraints to convert the raw instrument signal to chemical information. As such, the proposed methodology demonstrates clear benefits over the traditional preprocessing in the calibration of the inert and feed mixture products without need of prior calibration experiments or heuristic input from the user.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge