A Method towards the Systematic Architecting of Functionally Safe Automated Driving -- Leveraging Diagnostic Specifications for FSC design

Paper and Code

Dec 06, 2019

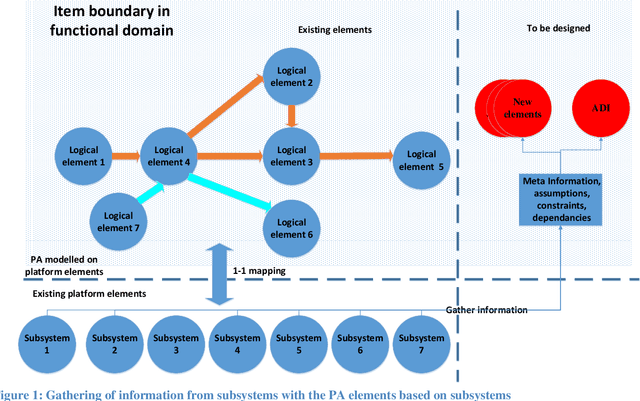

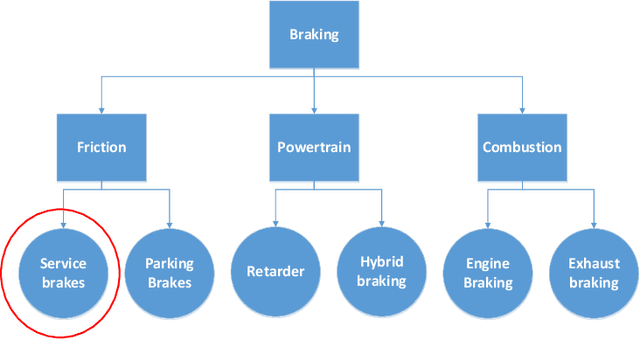

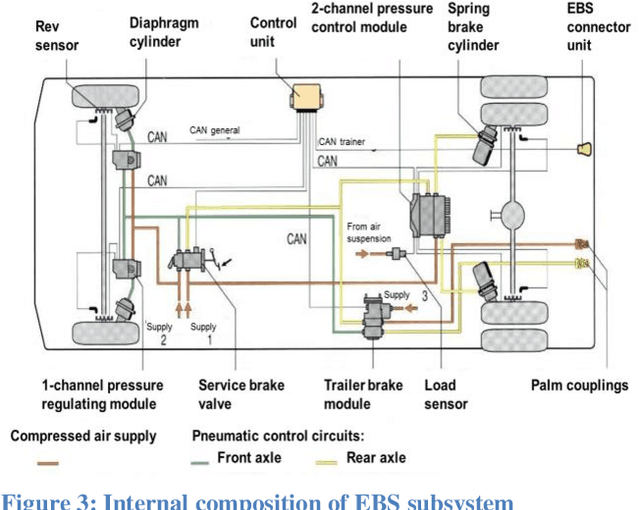

With the advent of ISO 26262 there is an increased emphasis on top-down design in the automotive industry. ISO 26262 lacks detailed requirements for its various constituent phases. The lack of guidance becomes evident for the reuse of legacy components and subsystems, leaving vehicle architects and safety engineers to rely on experience without methodological support for their decisions. This poses challenges in the industry which is undergoing many significant changes due to new features like connectivity, electrification and automation. Here we focus on automated driving where multiple subsystems, both new and legacy, need to coordinate to realize a safety-critical function. This paper introduces a method to support consistent design of an ISO 26262 work product, the Functional Safety Concept (FSC). The method addresses a need within the industry for architectural analysis, rationale management and reuse of legacy subsystems. The method makes use of an existing work product, the diagnostic specifications of a subsystem, to assist in performing a systematic assessment of the influence a human driver, in the design of the subsystem. The output of the method is a report with an abstraction level suitable for a vehicle architect, used as a basis for decisions related to the FSC such as generating a Preliminary Architecture (PA) and building up argumentation for verification of the FSC. The proposed method is tested in a safety-critical braking subsystem at one of the largest heavy vehicle manufacturers in Sweden, Scania C.V. AB. The results demonstrate the benefits of the method including (i) reuse of pre-existing work products, (ii) gathering requirements for automated driving functions while designing the PA and FSC, (iii) the parallelization of work across the organization on the basis of expertise, and (iv) the applicability of the method across all types of subsystems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge