A general anomaly detection framework for fleet-based condition monitoring of machines

Paper and Code

Jan 07, 2020

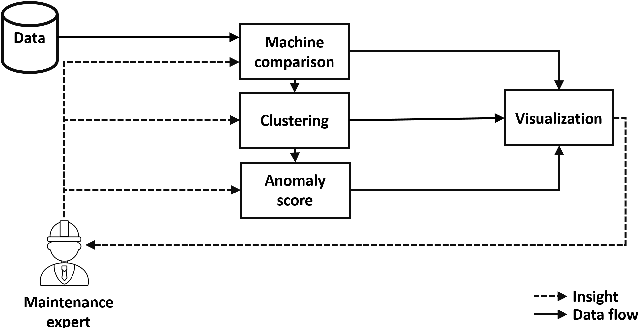

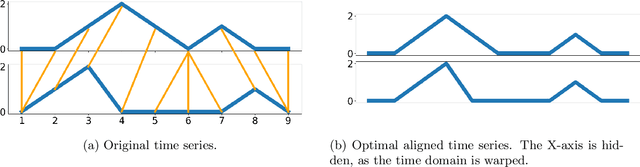

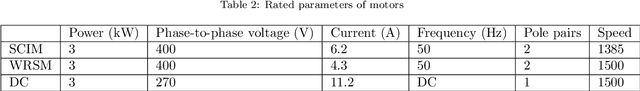

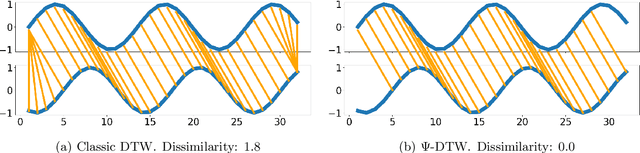

Machine failures decrease up-time and can lead to extra repair costs or even to human casualties and environmental pollution. Recent condition monitoring techniques use artificial intelligence in an effort to avoid time-consuming manual analysis and handcrafted feature extraction. Many of these only analyze a single machine and require a large historical data set. In practice, this can be difficult and expensive to collect. However, some industrial condition monitoring applications involve a fleet of similar operating machines. In most of these applications, it is safe to assume healthy conditions for the majority of machines. Deviating machine behavior is then an indicator for a machine fault. This work proposes an unsupervised, generic, anomaly detection framework for fleet-based condition monitoring. It uses generic building blocks and offers three key advantages. First, a historical data set is not required due to online fleet-based comparisons. Second, it allows incorporating domain expertise by user-defined comparison measures. Finally, contrary to most black-box artificial intelligence techniques, easy interpretability allows a domain expert to validate the predictions made by the framework. Two use-cases on an electrical machine fleet demonstrate the applicability of the framework to detect a voltage unbalance by means of electrical and vibration signatures.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge