Yuancan Huang

Design and Control of an Ultra-Slender Push-Pull Multisection Continuum Manipulator for In-Situ Inspection of Aeroengine

Dec 04, 2024

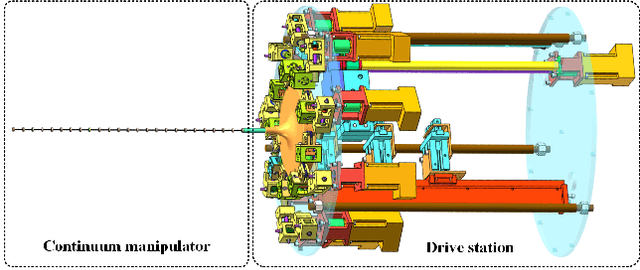

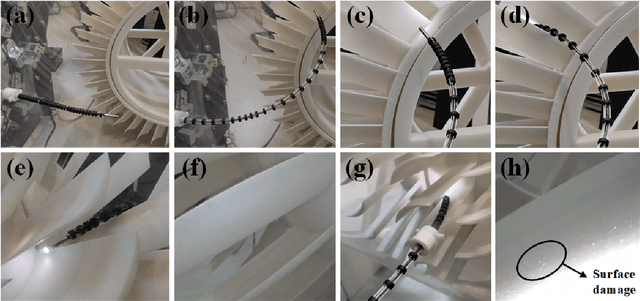

Abstract:Since the shape of industrial endoscopes is passively altered according to the contact around it, manual inspection approaches of aeroengines through the inspection ports have unreachable areas, and it's difficult to traverse multistage blades and inspect them simultaneously, which requires engine disassembly or the cooperation of multiple operators, resulting in efficiency decline and increased costs. To this end, this paper proposes a novel continuum manipulator with push-pull multisection structure which provides a potential solution for the disadvantages mentioned above due to its higher flexibility, passability, and controllability in confined spaces. The ultra-slender design combined with a tendon-driven mechanism makes the manipulator acquire enough workspace and more flexible postures while maintaining a light weight. Considering the coupling between the tendons in multisection, a innovative kinematics decoupling control method is implemented, which can realize real-time control in the case of limited computational resources. A prototype is built to validate the capabilities of mechatronic design and the performance of the control algorithm. The experimental results demonstrate the advantages of our continuum manipulator in the in-situ inspection of aeroengines' multistage blades, which has the potential to be a replacement solution for industrial endoscopes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge