Valentin Stegmaier

Illustrating the benefits of efficient creation and adaption of behavior models in intelligent Digital Twins over the machine life cycle

Jun 12, 2024

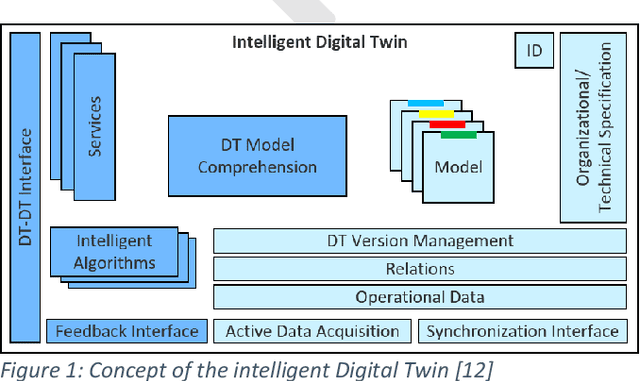

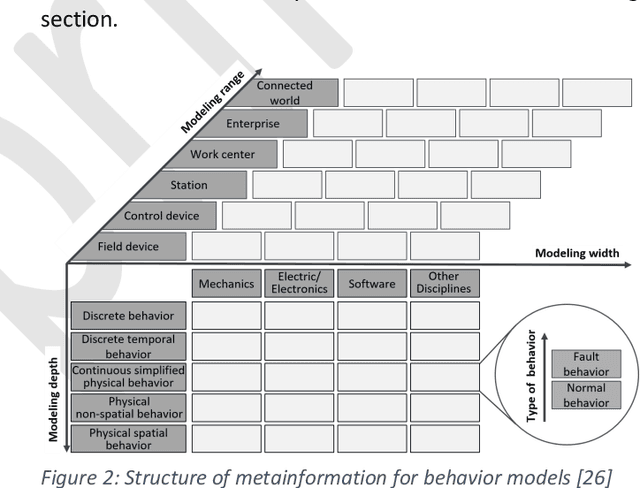

Abstract:The concept of the Digital Twin, which in the context of this paper is the virtual representation of a production system or its components, can be used as a "digital playground" to master the increasing complexity of these assets. Central subcomponents of the Digital Twin are behavior models that can provide benefits over the entire machine life cycle. However, the creation, adaption and use of behavior models throughout the machine life cycle is very time-consuming, which is why approaches to improve the cost-benefit ratio are needed. Furthermore, there is a lack of specific use cases that illustrate the application and added benefit of behavior models over the machine life cycle, which is why the universal application of behavior models in industry is still lacking compared to research. This paper first presents the fundamentals, challenges and related work on Digital Twins and behavior models in the context of the machine life cycle. Then, concepts for low-effort creation and automatic adaption of Digital Twins are presented, with a focus on behavior models. Finally, the aforementioned gap between research and industry is addressed by demonstrating various realized use cases over the machine life cycle, in which the advantages as well as the application of behavior models in the different life phases are shown.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge