Tobias Nagel

Sample-Efficient Bayesian Transfer Learning for Online Machine Parameter Optimization

Mar 21, 2025

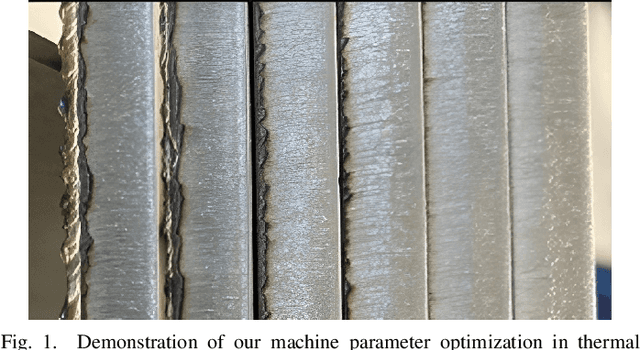

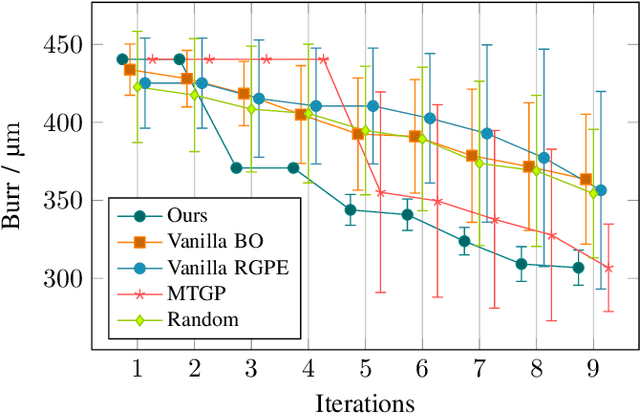

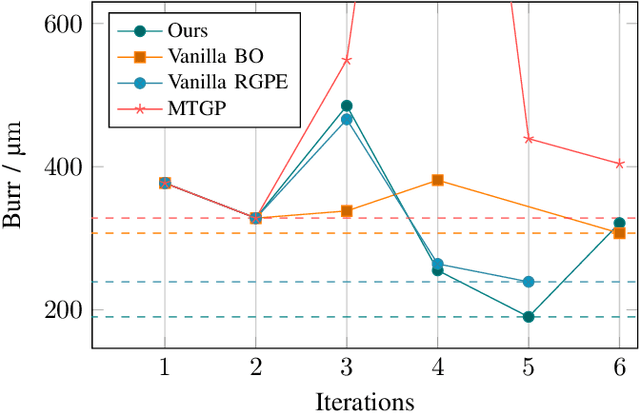

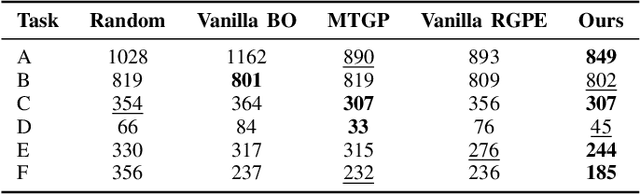

Abstract:Correctly setting the parameters of a production machine is essential to improve product quality, increase efficiency, and reduce production costs while also supporting sustainability goals. Identifying optimal parameters involves an iterative process of producing an object and evaluating its quality. Minimizing the number of iterations is, therefore, desirable to reduce the costs associated with unsuccessful attempts. This work introduces a method to optimize the machine parameters in the system itself using a Bayesian optimization algorithm. By leveraging existing machine data, we use a transfer learning approach in order to identify an optimum with minimal iterations, resulting in a cost-effective transfer learning algorithm. We validate our approach on a laser machine for cutting sheet metal in the real world.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge