Stanislav Jaso

Physics-informed neural networks need a physicist to be accurate: the case of mass and heat transport in Fischer-Tropsch catalyst particles

Nov 15, 2024

Abstract:Physics-Informed Neural Networks (PINNs) have emerged as an influential technology, merging the swift and automated capabilities of machine learning with the precision and dependability of simulations grounded in theoretical physics. PINNs are often employed to solve algebraic or differential equations to replace some or even all steps of multi-stage computational workflows, leading to their significant speed-up. However, wide adoption of PINNs is still hindered by reliability issues, particularly at extreme ends of the input parameter ranges. In this study, we demonstrate this in the context of a system of coupled non-linear differential reaction-diffusion and heat transfer equations related to Fischer-Tropsch synthesis, which are solved by a finite-difference method with a PINN used in evaluating their source terms. It is shown that the testing strategies traditionally used to assess the accuracy of neural networks as function approximators can overlook the peculiarities which ultimately cause instabilities of the finite-difference solver. We propose a domain knowledge-based modifications to the PINN architecture ensuring its correct asymptotic behavior. When combined with an improved numerical scheme employed as an initial guess generator, the proposed modifications are shown to recover the overall stability of the simulations, while preserving the speed-up brought by PINN as the workflow component. We discuss the possible applications of the proposed hybrid transport equation solver in context of chemical reactors simulations.

Accurate and Fast Fischer-Tropsch Reaction Microkinetics using PINNs

Nov 17, 2023

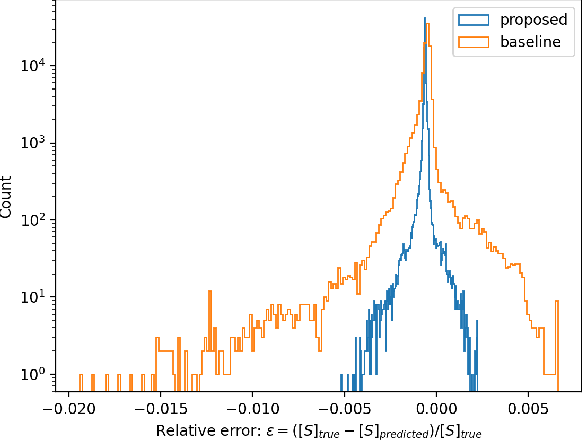

Abstract:Microkinetics allows detailed modelling of chemical transformations occurring in many industrially relevant reactions. Traditional way of solving the microkinetics model for Fischer-Tropsch synthesis (FTS) becomes inefficient when it comes to more advanced real-time applications. In this work, we address these challenges by using physics-informed neural networks(PINNs) for modelling FTS microkinetics. We propose a computationally efficient and accurate method, enabling the ultra-fast solution of the existing microkinetics models in realistic process conditions. The proposed PINN model computes the fraction of vacant catalytic sites, a key quantity in FTS microkinetics, with median relative error (MRE) of 0.03%, and the FTS product formation rates with MRE of 0.1%. Compared to conventional equation solvers, the model achieves up to 1E+06 times speed-up when running on GPUs, thus being fast enough for multi-scale and multi-physics reactor modelling and enabling its applications in real-time process control and optimization.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge