Sina Ardabili

Integration of neural network and fuzzy logic decision making compared with bilayered neural network in the simulation of daily dew point temperature

Feb 23, 2022

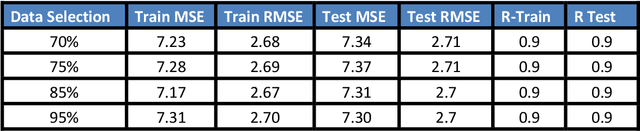

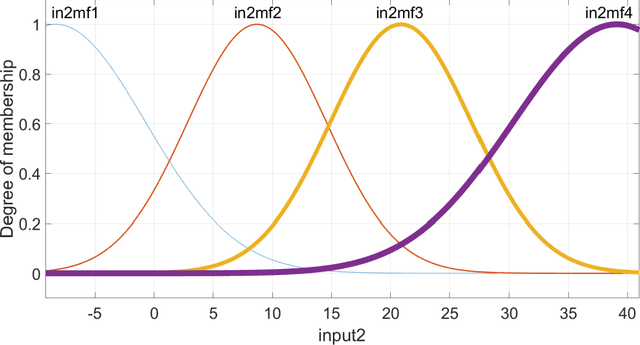

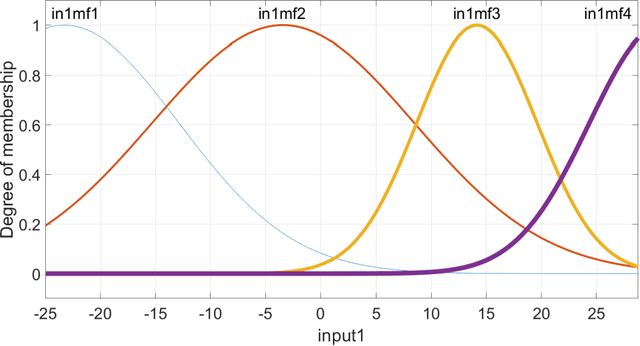

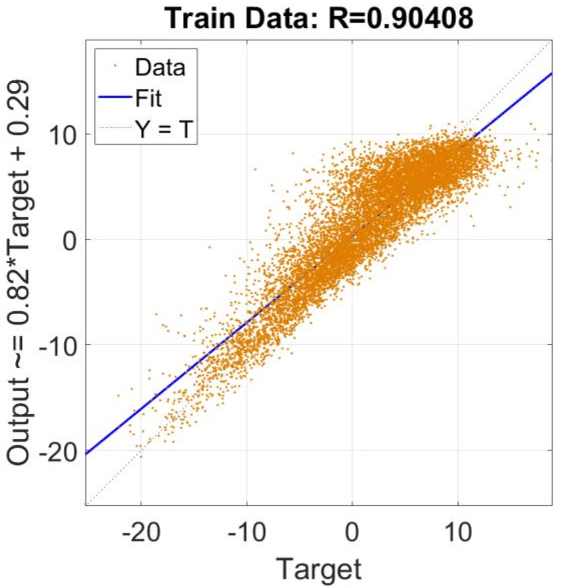

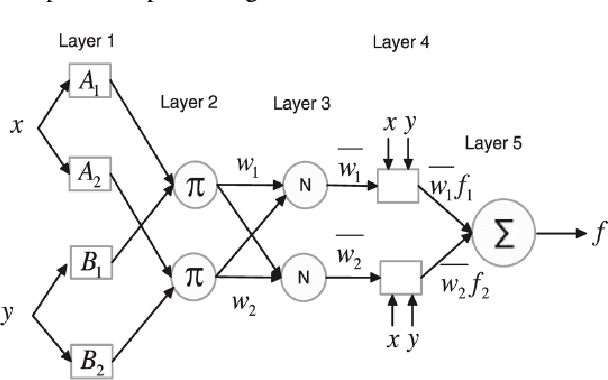

Abstract:In this research, dew point temperature (DPT) is simulated using the data-driven approach. Adaptive Neuro-Fuzzy Inference System (ANFIS) is utilized as a data-driven technique to forecast this parameter at Tabriz in East Azerbaijan. Various input patterns, namely T min, T max, and T mean, are utilized for training the architecture whilst DPT is the model's output. The findings indicate that, in general, ANFIS method is capable of identifying data patterns with a high degree of accuracy. However, the approach demonstrates that processing time and computer resources may substantially increase by adding additional functions. Based on the results, the number of iterations and computing resources might change dramatically if new functionalities are included. As a result, tuning parameters have to be optimized inside the method framework. The findings demonstrate a high agreement between results by the data-driven technique (machine learning method) and the observed data. Using this prediction toolkit, DPT can be adequately forecasted solely based on the temperature distribution of Tabriz. This kind of modeling is extremely promising for predicting DPT at various sites. Besides, this study thoroughly compares the Bilayered Neural Network (BNN) and ANFIS models on various scales. Whilst the ANFIS model is extremely stable for almost all numbers of membership functions, the BNN model is highly sensitive to this scale factor to predict DPT.

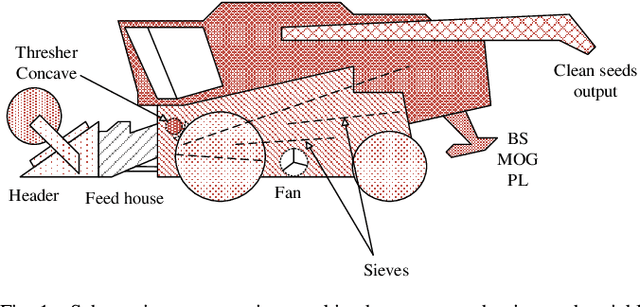

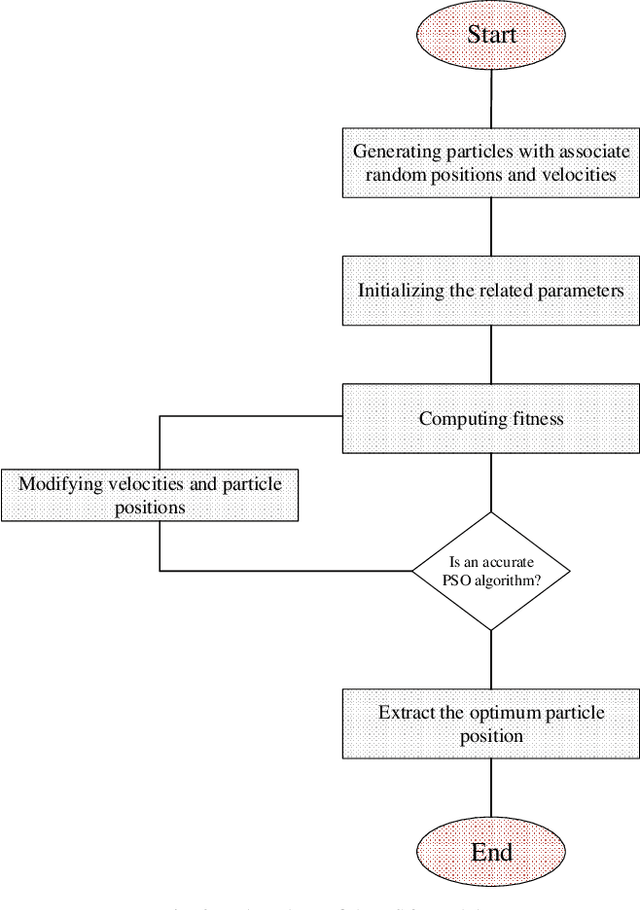

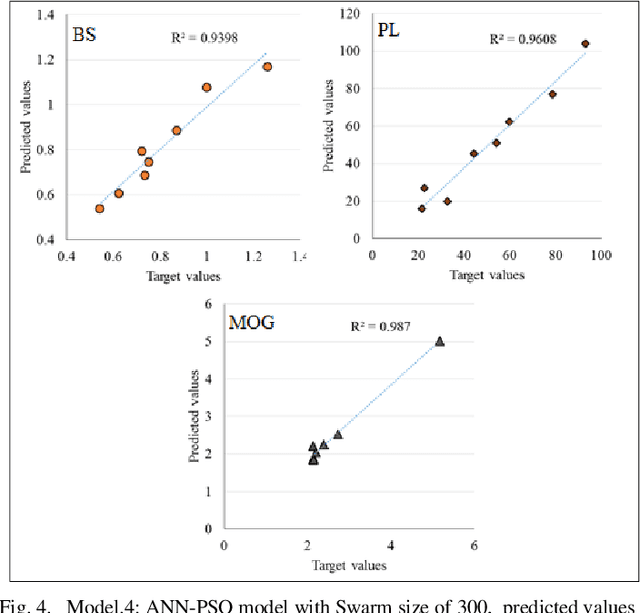

Performance Analysis of Combine Harvester using Hybrid Model of Artificial Neural Networks Particle Swarm Optimization

Feb 22, 2020

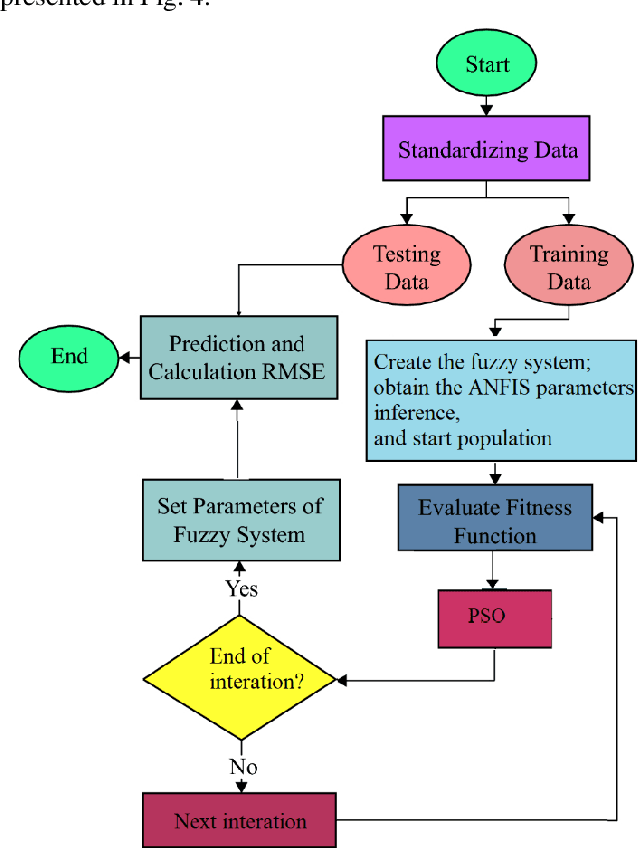

Abstract:Novel applications of artificial intelligence for tuning the parameters of industrial machines for optimal performance are emerging at a fast pace. Tuning the combine harvesters and improving the machine performance can dramatically minimize the wastes during harvesting, and it is also beneficial to machine maintenance. Literature includes several soft computing, machine learning and optimization methods that had been used to model the function of harvesters of various crops. Due to the complexity of the problem, machine learning methods had been recently proposed to predict the optimal performance with promising results. In this paper, through proposing a novel hybrid machine learning model based on artificial neural networks integrated with particle swarm optimization (ANN-PSO), the performance analysis of a common combine harvester is presented. The hybridization of machine learning methods with soft computing techniques has recently shown promising results to improve the performance of the combine harvesters. This research aims at improving the results further by providing more stable models with higher accuracy.

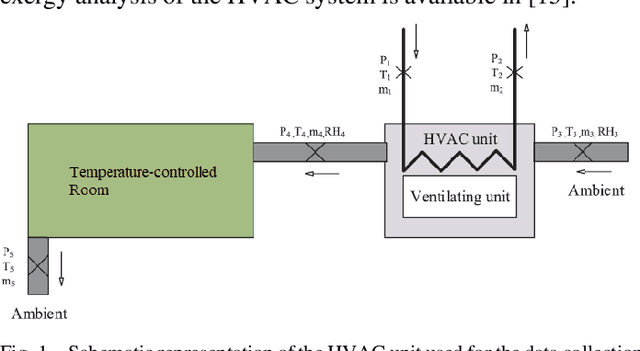

Comparative Analysis of Single and Hybrid Neuro-Fuzzy-Based Models for an Industrial Heating Ventilation and Air Conditioning Control System

Feb 22, 2020

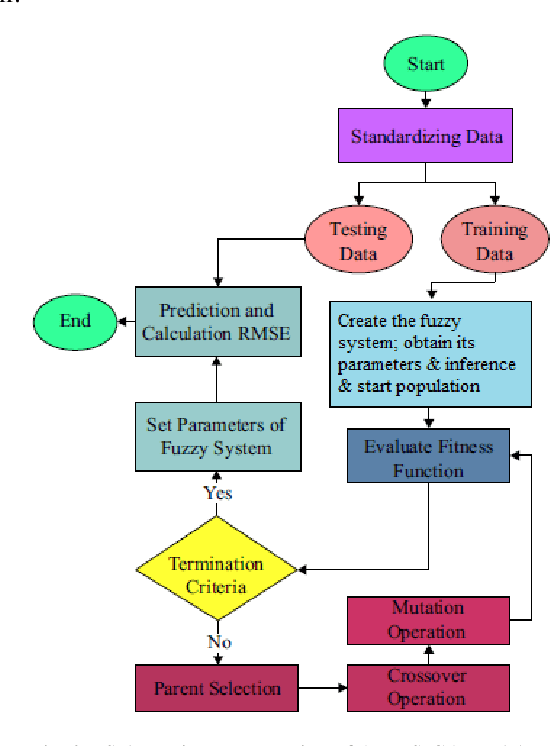

Abstract:Hybridization of machine learning methods with soft computing techniques is an essential approach to improve the performance of the prediction models. Hybrid machine learning models, particularly, have gained popularity in the advancement of the high-performance control systems. Higher accuracy and better performance for prediction models of exergy destruction and energy consumption used in the control circuit of heating, ventilation, and air conditioning (HVAC) systems can be highly economical in the industrial scale to save energy. This research proposes two hybrid models of adaptive neuro-fuzzy inference system-particle swarm optimization (ANFIS-PSO), and adaptive neuro-fuzzy inference system-genetic algorithm (ANFIS-GA) for HVAC. The results are further compared with the single ANFIS model. The ANFIS-PSO model with the RMSE of 0.0065, MAE of 0.0028, and R2 equal to 0.9999, with a minimum deviation of 0.0691 (KJ/s), outperforms the ANFIS-GA and single ANFIS models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge