Siddharth Tallur

Smart structural health monitoring (SHM) system for on-board localization of defects in pipes using torsional ultrasonic guided waves

Mar 17, 2024Abstract:Most reported research for monitoring health of pipelines using ultrasonic guided waves (GW) typically utilize bulky piezoelectric transducer rings and laboratory-grade ultrasonic non-destructive testing (NDT) equipment. Consequently, the translation of these approaches from laboratory settings to field-deployable systems for real-time structural health monitoring (SHM) becomes challenging. In this work, we present an innovative algorithm for damage identification and localization in pipes, implemented on a compact FPGA-based smart GW-SHM system. The custom-designed board, featuring a Xilinx Artix-7 FPGA and front-end electronics, is capable of actuating the PZT thickness shear mode transducers, data acquisition and recording from PZT sensors and generating a damage index (DI) map for localizing the damage on the structure. The algorithm is a variation of the common source method adapted for cylindrical geometry. The utility of the algorithm is demonstrated for detection and localization of defects such as notch and mass loading on a steel pipe, through extensive finite element (FE) method simulations. Experimental results obtained using a C-clamp for applying mass loading on the pipe show good agreement with the FE simulations. The localization error values for experimental data analyzed using C code on a processor implemented on the FPGA are consistent with algorithm results generated on a computer running MATLAB code. The system presented in this study is suitable for a wide range of GW-SHM applications, especially in cost-sensitive scenarios that benefit from on-node signal processing over cloud-based solutions.

Classification of Various Types of Damages in Honeycomb Composite Sandwich Structures using Guided Wave Structural Health Monitoring

Nov 07, 2023

Abstract:Classification of damages in honeycomb composite sandwich structure (HCSS) is important to decide remedial actions. However, previous studies have only detected damages using deviations of monitoring signal from healthy (baseline) using a guided wave (GW) based structural health monitoring system. Classification between various types of damages has not been reported for challenging cases. We show that using careful feature engineering and machine learning it is possible to classify between various types of damages such as core crush (CC), high density core (HDC), lost film adhesive (LFA) and teflon release film (TRF). We believe that we are the first to report numerical models for four types of damages in HCSS, which is followed up with experimental validation. We found that two out of four damages affect the GW signal in a particularly similar manner. We extracted and evaluated multiple features from time as well as frequency domains, and also experimented with features relative to as baseline as well as those that were baseline-free. Using Pearson's correlation coefficient based filtering, redundant features were eliminated. Finally, using an optimal feature set determined using feature elimination, high accuracy was achieved with a random forest classifier on held-out signals. For evaluating performance of the proposed method for different damage sizes, we used simulated data obtained from extensive parametric studies and got an accuracy of 77.89%. Interpretability studies to determine importance of various features showed that features computed using the baseline signal prove more effective as compared to baseline-free features.

Unsupervised deep learning framework for temperature-compensated damage assessment using ultrasonic guided waves on edge device

Oct 08, 2023Abstract:Fueled by the rapid development of machine learning (ML) and greater access to cloud computing and graphics processing units (GPUs), various deep learning based models have been proposed for improving performance of ultrasonic guided wave structural health monitoring (GW-SHM) systems, especially to counter complexity and heterogeneity in data due to varying environmental factors (e.g., temperature) and types of damages. Such models typically comprise of millions of trainable parameters, and therefore add to cost of deployment due to requirements of cloud connectivity and processing, thus limiting the scale of deployment of GW-SHM. In this work, we propose an alternative solution that leverages TinyML framework for development of light-weight ML models that could be directly deployed on embedded edge devices. The utility of our solution is illustrated by presenting an unsupervised learning framework for damage detection in honeycomb composite sandwich structure (HCSS) with disbond and delamination type of damages, validated using data generated by finite element (FE) simulations and experiments performed at various temperatures in the range 0{\deg}C to 90{\deg}C. We demonstrate a fully-integrated solution using a Xilinx Artix-7 FPGA for data acquisition and control, and edge-inference of damage.

Environmental variation compensated damage classification and localization in ultrasonic guided wave SHM using self-learnt features and Gaussian mixture models

Nov 11, 2021

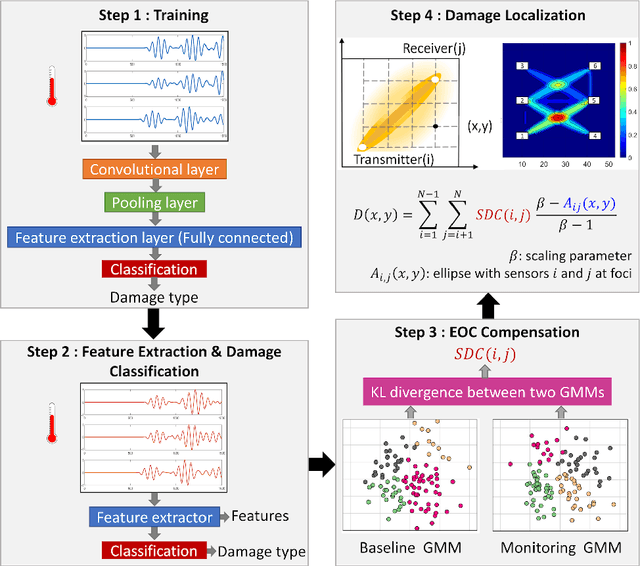

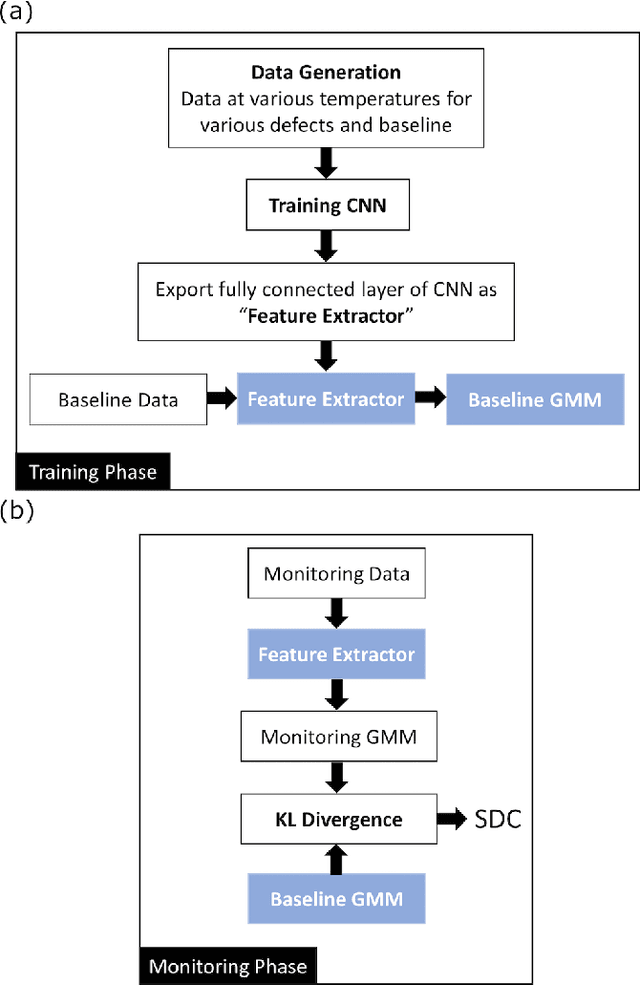

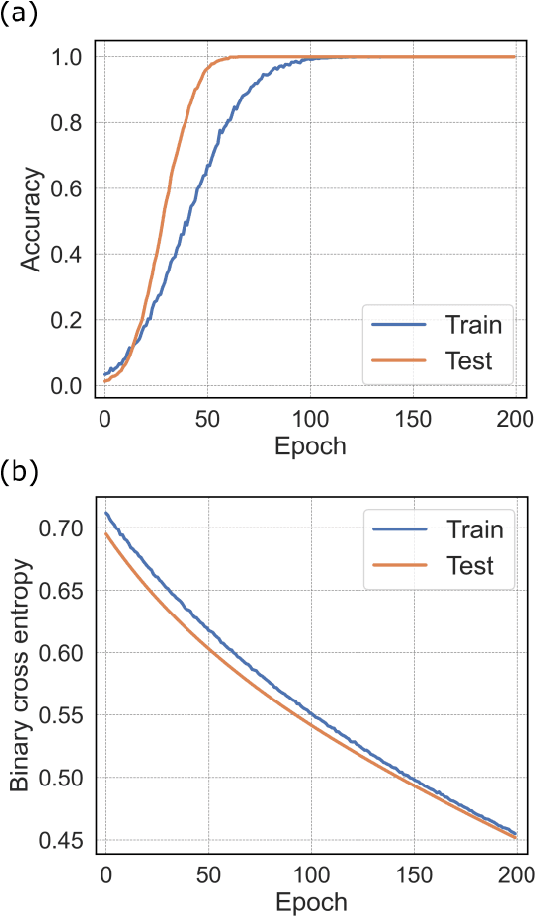

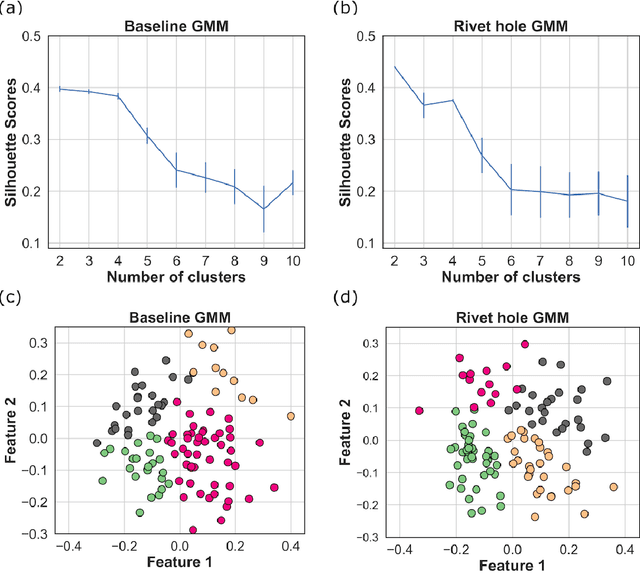

Abstract:Conventional damage localization algorithms used in ultrasonic guided wave-based structural health monitoring (GW-SHM) rely on physics-defined features of GW signals. In addition to requiring domain knowledge of the interaction of various GW modes with various types of damages, they also suffer from errors due to variations in environmental and operating conditions (EOCs) in practical use cases. While several machine learning tools have been reported for EOC compensation, they need to be custom-designed for each combination of damage and structure due to their dependence on physics-defined feature extraction. In this work, we propose a CNN-based automated feature extraction framework coupled with Gaussian mixture model (GMM) based EOC compensation and damage classification and localization method. Features learnt by the CNNs are used for damage classification and localization of damage by modeling the probability distribution of the features using GMMs. The Kullback-Leibler (KL) divergence of these GMMs with respect to corresponding baseline GMMs are used as signal difference coefficients (SDCs) to compute damage indices (DIs) along various GW sensor paths, and thus for damage localization. The efficacy of the proposed method is demonstrated using FE generated GW-data for an aluminum plate with a network of six lead zirconate titanate (PZT) sensors, for three different types of damages (rivet hole, added mass, notch) at various temperatures, with added white noise and pink noise to incorporate errors due to EOCs. We also present experimental validation of the method through characterization of notch damage in an aluminum panel under varying and non-uniform temperature profiles, using a portable custom-designed field programmable gate array (FPGA) based signal transduction and data acquisition system.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge