Selim Arikan

Surface Defect Classification in Real-Time Using Convolutional Neural Networks

Apr 07, 2019

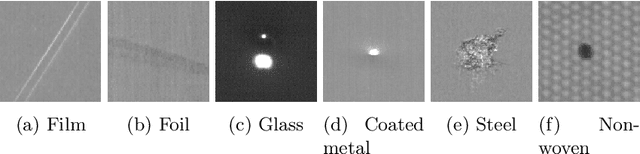

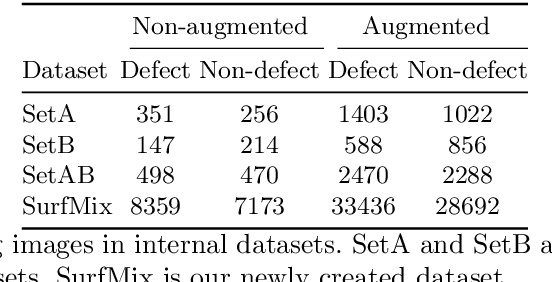

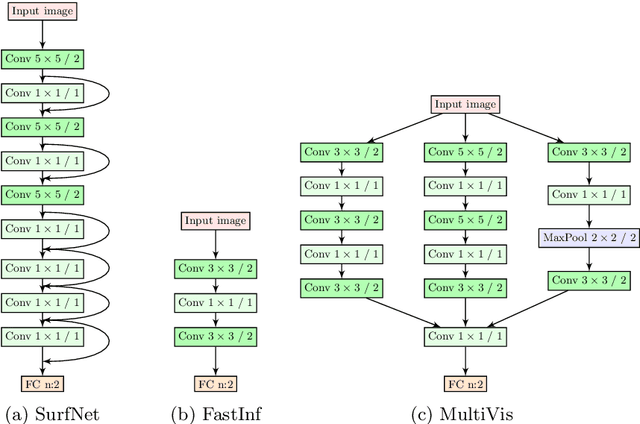

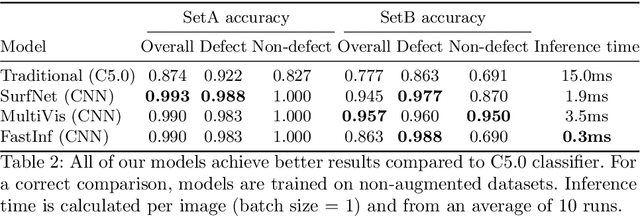

Abstract:Surface inspection systems are an important application domain for computer vision, as they are used for defect detection and classification in the manufacturing industry. Existing systems use hand-crafted features which require extensive domain knowledge to create. Even though Convolutional neural networks (CNNs) have proven successful in many large-scale challenges, industrial inspection systems have yet barely realized their potential due to two significant challenges: real-time processing speed requirements and specialized narrow domain-specific datasets which are sometimes limited in size. In this paper, we propose CNN models that are specifically designed to handle capacity and real-time speed requirements of surface inspection systems. To train and evaluate our network models, we created a surface image dataset containing more than 22000 labeled images with many types of surface materials and achieved 98.0% accuracy in binary defect classification. To solve the class imbalance problem in our datasets, we introduce neural data augmentation methods which are also applicable to similar domains that suffer from the same problem. Our results show that deep learning based methods are feasible to be used in surface inspection systems and outperform traditional methods in accuracy and inference time by considerable margins.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge