Sebastian R. Bader

The Semantic Asset Administration Shell

Sep 02, 2019

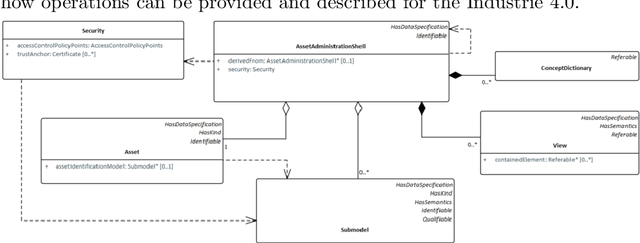

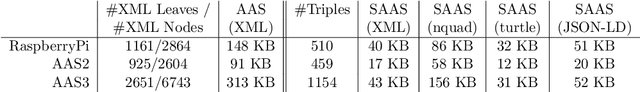

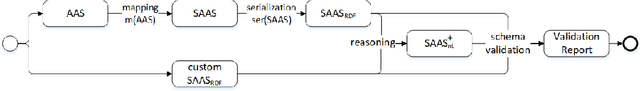

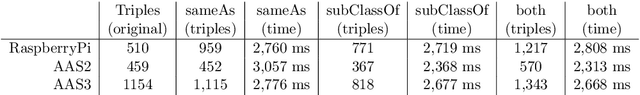

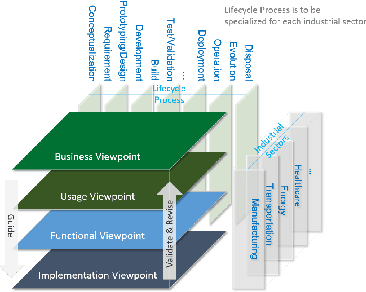

Abstract:The disruptive potential of the upcoming digital transformations for the industrial manufacturing domain have led to several reference frameworks and numerous standardization approaches. On the other hand, the Semantic Web community has made significant contributions in the field, for instance on data and service description, integration of heterogeneous sources and devices, and AI techniques in distributed systems. These two streams of work are, however, mostly unrelated and only briefly regard each others requirements, practices and terminology. We contribute to closing this gap by providing the Semantic Asset Administration Shell, an RDF-based representation of the Industrie 4.0 Component. We provide an ontology for the latest data model specification, created a RML mapping, supply resources to validate the RDF entities and introduce basic reasoning on the Asset Administration Shell data model. Furthermore, we discuss the different assumptions and presentation patterns, and analyze the implications of a semantic representation on the original data. We evaluate the thereby created overheads, and conclude that the semantic lifting is manageable, also for restricted or embedded devices, and therefore meets the needs of Industrie 4.0 scenarios.

Virtual Representations for Iterative IoT Deployment

Mar 02, 2019

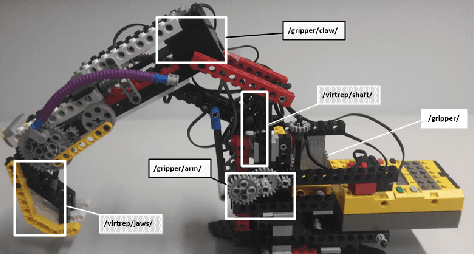

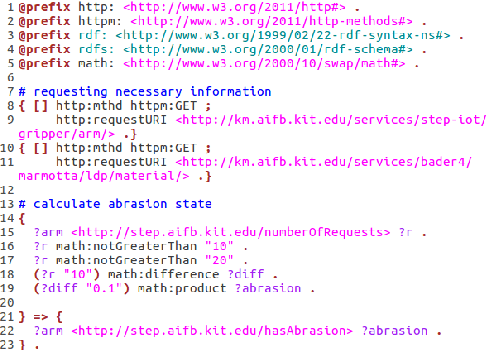

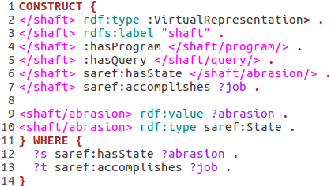

Abstract:A central vision of the Internet of Things is the representation of the physical world in a consistent virtual environment. Especially in the context of smart factories the connection of the different, heterogeneous production modules through a digital shop floor promises faster conversion rates, data-driven maintenance or automated machine configurations for use cases, which have not been known at design time. Nevertheless, these scenarios demand IoT representations of all participating machines and components, which requires high installation efforts and hardware adjustments. We propose an incremental process for bringing the shop floor closer to the IoT vision. Currently the majority of systems, components or parts are not yet connected with the internet and might not even provide the possibility to be technically equipped with sensors. However, those could be essential parts for a realistic digital shop floor representation. We, therefore, propose Virtual Representations, which are capable of independently calculating a physical object's condition by dynamically collecting and interpreting already available data through RESTful Web APIs. The internal logic of such Virtual Representations are further adjustable at runtime, since changes to its respective physical object, its environment or updates to the resource itself should not cause any downtime.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge