Ryan Myers

LTV-YOLO: A Lightweight Thermal Object Detector for Young Pedestrians in Adverse Conditions

Jan 15, 2026Abstract:Detecting vulnerable road users (VRUs), particularly children and adolescents, in low light and adverse weather conditions remains a critical challenge in computer vision, surveillance, and autonomous vehicle systems. This paper presents a purpose-built lightweight object detection model designed to identify young pedestrians in various environmental scenarios. To address these challenges, our approach leverages thermal imaging from long-wave infrared (LWIR) cameras, which enhances detection reliability in conditions where traditional RGB cameras operating in the visible spectrum fail. Based on the YOLO11 architecture and customized for thermal detection, our model, termed LTV-YOLO (Lightweight Thermal Vision YOLO), is optimized for computational efficiency, accuracy and real-time performance on edge devices. By integrating separable convolutions in depth and a feature pyramid network (FPN), LTV-YOLO achieves strong performance in detecting small-scale, partially occluded, and thermally distinct VRUs while maintaining a compact architecture. This work contributes a practical and scalable solution to improve pedestrian safety in intelligent transportation systems, particularly in school zones, autonomous navigation, and smart city infrastructure. Unlike prior thermal detectors, our contribution is task-specific: a thermally only edge-capable design designed for young and small VRUs (children and distant adults). Although FPN and depthwise separable convolutions are standard components, their integration into a thermal-only pipeline optimized for short/occluded VRUs under adverse conditions is, to the best of our knowledge, novel.

Similarity-Based Predictive Maintenance Framework for Rotating Machinery

Dec 30, 2022

Abstract:Within smart manufacturing, data driven techniques are commonly adopted for condition monitoring and fault diagnosis of rotating machinery. Classical approaches use supervised learning where a classifier is trained on labeled data to predict or classify different operational states of the machine. However, in most industrial applications, labeled data is limited in terms of its size and type. Hence, it cannot serve the training purpose. In this paper, this problem is tackled by addressing the classification task as a similarity measure to a reference sample rather than a supervised classification task. Similarity-based approaches require a limited amount of labeled data and hence, meet the requirements of real-world industrial applications. Accordingly, the paper introduces a similarity-based framework for predictive maintenance (PdM) of rotating machinery. For each operational state of the machine, a reference vibration signal is generated and labeled according to the machine's operational condition. Consequentially, statistical time analysis, fast Fourier transform (FFT), and short-time Fourier transform (STFT) are used to extract features from the captured vibration signals. For each feature type, three similarity metrics, namely structural similarity measure (SSM), cosine similarity, and Euclidean distance are used to measure the similarity between test signals and reference signals in the feature space. Hence, nine settings in terms of feature type-similarity measure combinations are evaluated. Experimental results confirm the effectiveness of similarity-based approaches in achieving very high accuracy with moderate computational requirements compared to machine learning (ML)-based methods. Further, the results indicate that using FFT features with cosine similarity would lead to better performance compared to the other settings.

A Hybrid Method for Condition Monitoring and Fault Diagnosis of Rolling Bearings With Low System Delay

Aug 11, 2022

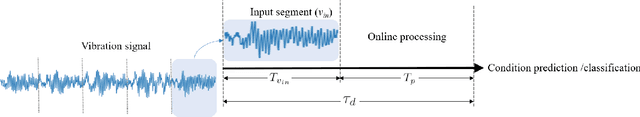

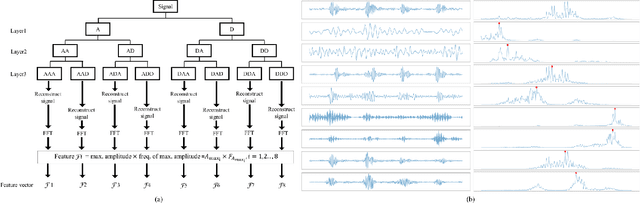

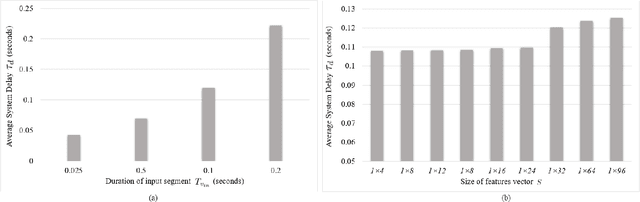

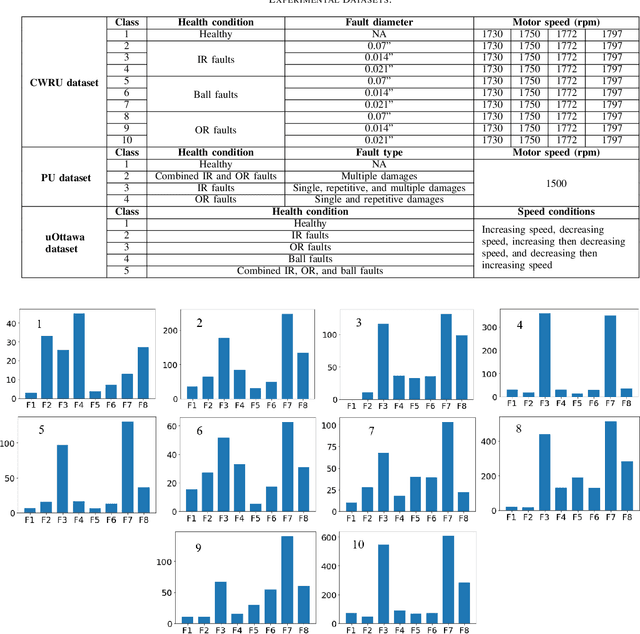

Abstract:Vibration-based condition monitoring techniques are commonly used to detect and diagnose failures of rolling bearings. Accuracy and delay in detecting and diagnosing different types of failures are the main performance measures in condition monitoring. Achieving high accuracy with low delay improves system reliability and prevents catastrophic equipment failure. Further, delay is crucial to remote condition monitoring and time-sensitive industrial applications. While most of the proposed methods focus on accuracy, slight attention has been paid to addressing the delay introduced in the condition monitoring process. In this paper, we attempt to bridge this gap and propose a hybrid method for vibration-based condition monitoring and fault diagnosis of rolling bearings that outperforms previous methods in terms of accuracy and delay. Specifically, we address the overall delay in vibration-based condition monitoring systems and introduce the concept of system delay to assess it. Then, we present the proposed method for condition monitoring. It uses Wavelet Packet Transform (WPT) and Fourier analysis to decompose short-duration input segments of the vibration signal into elementary waveforms and obtain their spectral contents. Accordingly, energy concentration in the spectral components-caused by defect induced transient vibrations-is utilized to extract a small number of features with high discriminative capabilities. Consequently, Bayesian optimization-based Random Forest (RF) algorithm is used to classify healthy and faulty operating conditions under varying motor speeds. The experimental results show that the proposed method can achieve high accuracy with low system delay.

An Attention-based ConvLSTM Autoencoder with Dynamic Thresholding for Unsupervised Anomaly Detection in Multivariate Time Series

Jan 23, 2022

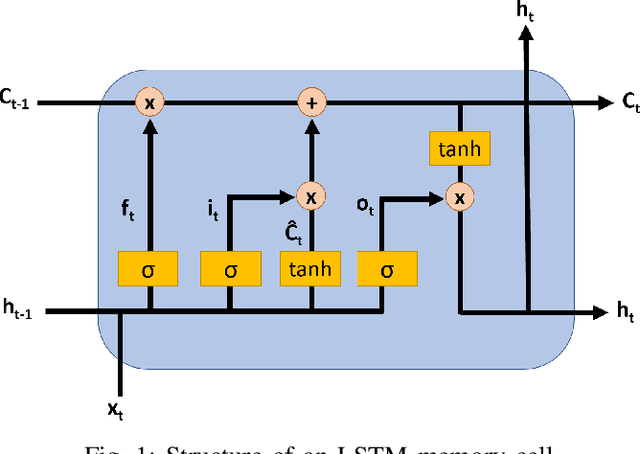

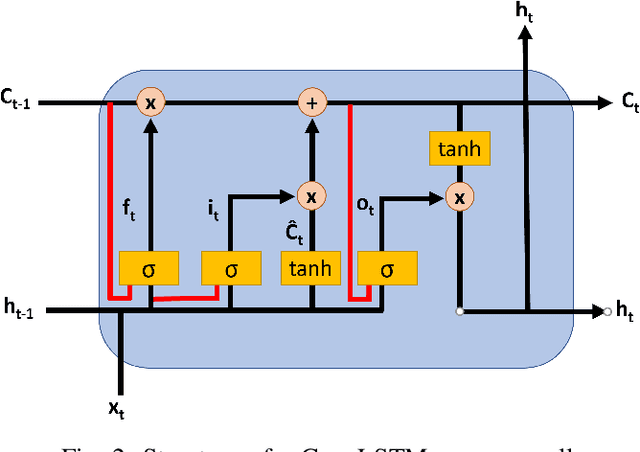

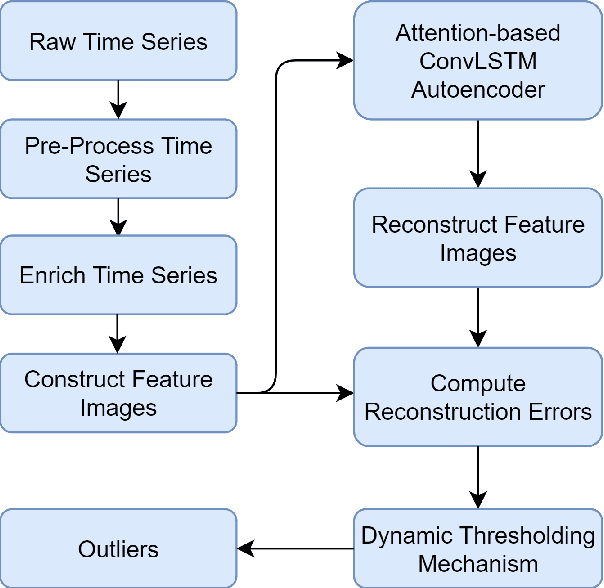

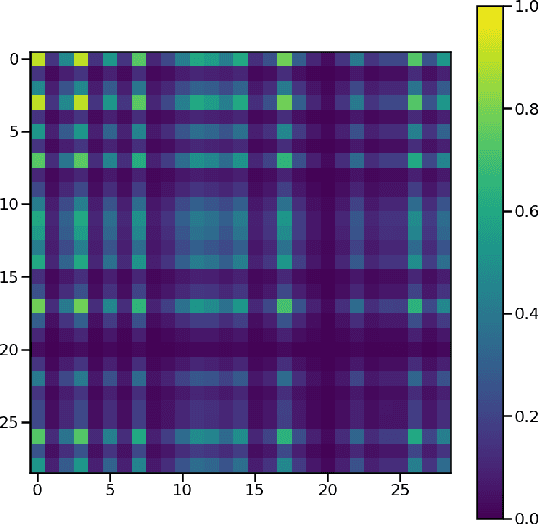

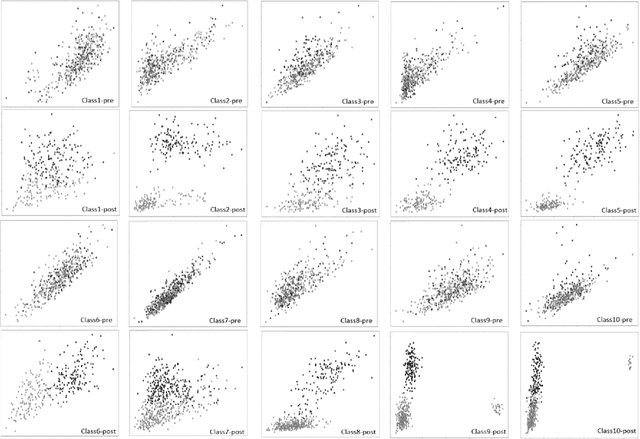

Abstract:As a substantial amount of multivariate time series data is being produced by the complex systems in Smart Manufacturing, improved anomaly detection frameworks are needed to reduce the operational risks and the monitoring burden placed on the system operators. However, building such frameworks is challenging, as a sufficiently large amount of defective training data is often not available and frameworks are required to capture both the temporal and contextual dependencies across different time steps while being robust to noise. In this paper, we propose an unsupervised Attention-based Convolutional Long Short-Term Memory (ConvLSTM) Autoencoder with Dynamic Thresholding (ACLAE-DT) framework for anomaly detection and diagnosis in multivariate time series. The framework starts by pre-processing and enriching the data, before constructing feature images to characterize the system statuses across different time steps by capturing the inter-correlations between pairs of time series. Afterwards, the constructed feature images are fed into an attention-based ConvLSTM autoencoder, which aims to encode the constructed feature images and capture the temporal behavior, followed by decoding the compressed knowledge representation to reconstruct the feature images input. The reconstruction errors are then computed and subjected to a statistical-based, dynamic thresholding mechanism to detect and diagnose the anomalies. Evaluation results conducted on real-life manufacturing data demonstrate the performance strengths of the proposed approach over state-of-the-art methods under different experimental settings.

A Transfer Learning Framework for Anomaly Detection Using Model of Normality

Nov 12, 2020

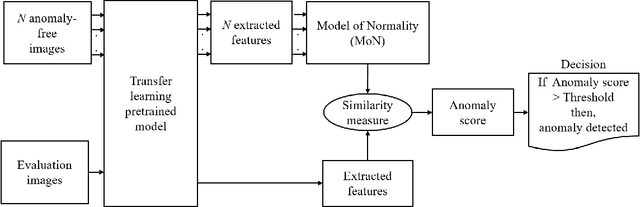

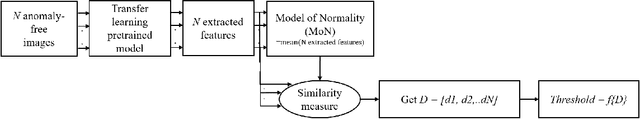

Abstract:Convolutional Neural Network (CNN) techniques have proven to be very useful in image-based anomaly detection applications. CNN can be used as deep features extractor where other anomaly detection techniques are applied on these features. For this scenario, using transfer learning is common since pretrained models provide deep feature representations that are useful for anomaly detection tasks. Consequentially, anomaly can be detected by applying similarly measure between extracted features and a defined model of normality. A key factor in such approaches is the decision threshold used for detecting anomaly. While most of the proposed methods focus on the approach itself, slight attention has been paid to address decision threshold settings. In this paper, we tackle this problem and propose a welldefined method to set the working-point decision threshold that improves detection accuracy. We introduce a transfer learning framework for anomaly detection based on similarity measure with a Model of Normality (MoN) and show that with the proposed threshold settings, a significant performance improvement can be achieved. Moreover, the framework has low complexity with relaxed computational requirements.

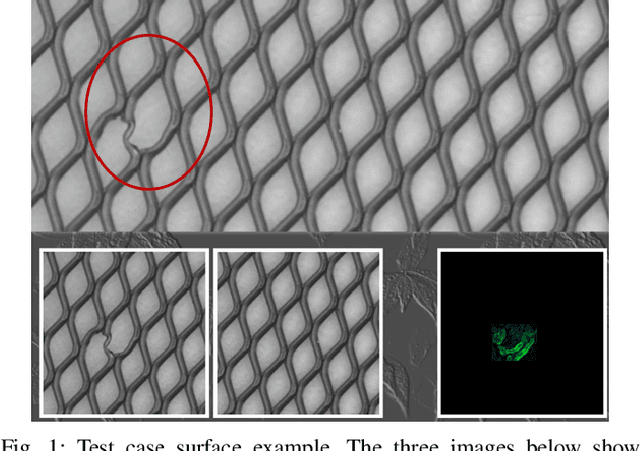

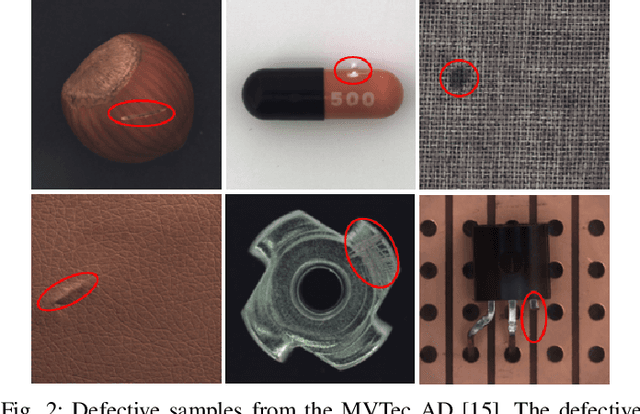

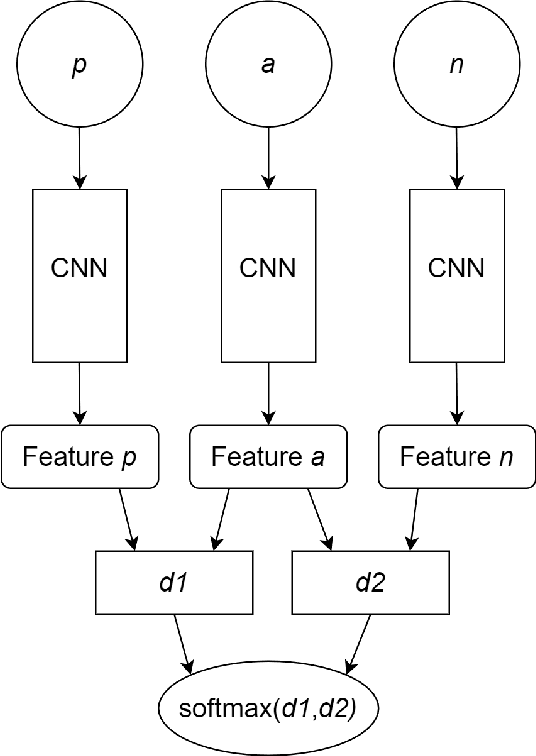

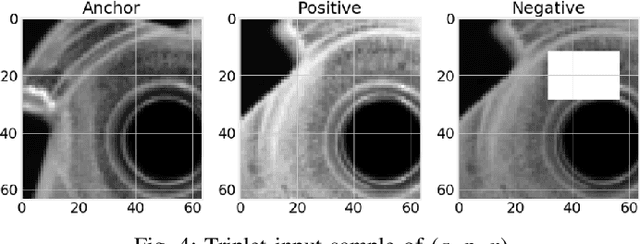

Distance-Based Anomaly Detection for Industrial Surfaces Using Triplet Networks

Nov 10, 2020

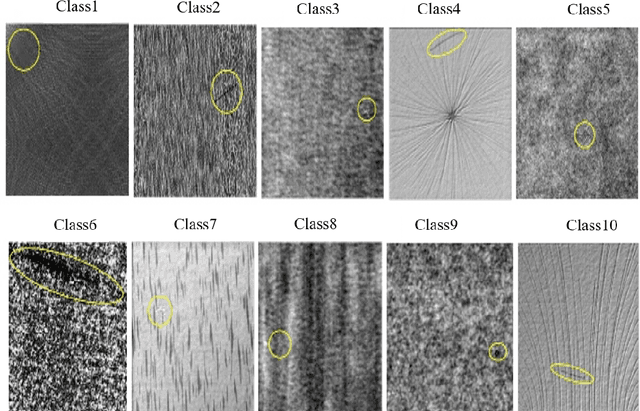

Abstract:Surface anomaly detection plays an important quality control role in many manufacturing industries to reduce scrap production. Machine-based visual inspections have been utilized in recent years to conduct this task instead of human experts. In particular, deep learning Convolutional Neural Networks (CNNs) have been at the forefront of these image processing-based solutions due to their predictive accuracy and efficiency. Training a CNN on a classification objective requires a sufficiently large amount of defective data, which is often not available. In this paper, we address that challenge by training the CNN on surface texture patches with a distance-based anomaly detection objective instead. A deep residual-based triplet network model is utilized, and defective training samples are synthesized exclusively from non-defective samples via random erasing techniques to directly learn a similarity metric between the same-class samples and out-of-class samples. Evaluation results demonstrate the approach's strength in detecting different types of anomalies, such as bent, broken, or cracked surfaces, for known surfaces that are part of the training data and unseen novel surfaces.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge