Mohammad Al-Sa'd

Semi-Supervised Co-Training of Time and Time-Frequency Models: Application to Bearing Fault Diagnosis

Mar 14, 2025

Abstract:Neural networks require massive amounts of annotated data to train intelligent solutions. Acquiring many labeled data in industrial applications is often difficult; therefore, semi-supervised approaches are preferred. We propose a new semi-supervised co-training method, which combines time and time-frequency (TF) machine learning models to improve performance and reliability. The developed framework collaboratively co-trains fast time-domain models by utilizing high-performing TF techniques without increasing the inference complexity. Besides, it operates in cloud-edge networks and offers holistic support for many applications covering edge-real-time monitoring and cloud-based updates and corrections. Experimental results on bearing fault diagnosis verify the superiority of our technique compared to a competing self-training method. The results from two case studies show that our method outperforms self-training for different noise levels and amounts of available data with accuracy gains reaching from 10.6% to 33.9%. They demonstrate that fusing time-domain and TF-based models offers opportunities for developing high-performance industrial solutions.

Quadratic Time-Frequency Analysis of Vibration Signals for Diagnosing Bearing Faults

Jan 02, 2024

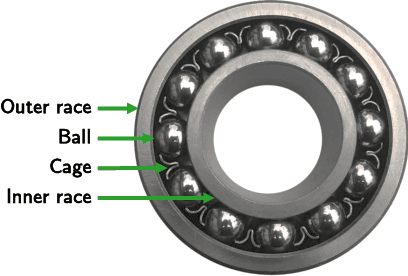

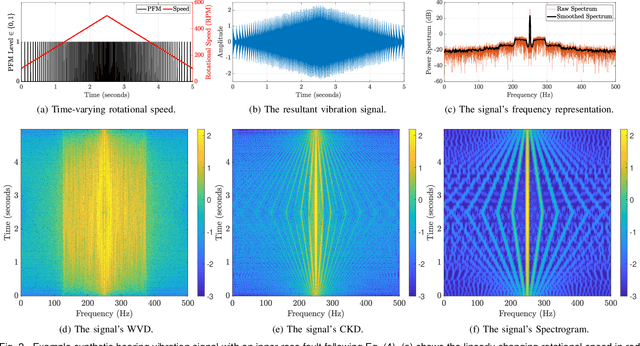

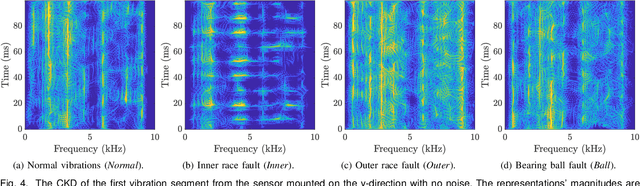

Abstract:Diagnosis of bearing faults is paramount to reducing maintenance costs and operational breakdowns. Bearing faults are primary contributors to machine vibrations, and analyzing their signal morphology offers insights into their health status. Unfortunately, existing approaches are optimized for controlled environments, neglecting realistic conditions such as time-varying rotational speeds and the vibration's non-stationary nature. This paper presents a fusion of time-frequency analysis and deep learning techniques to diagnose bearing faults under time-varying speeds and varying noise levels. First, we formulate the bearing fault-induced vibrations and discuss the link between their non-stationarity and the bearing's inherent and operational parameters. We also elucidate quadratic time-frequency distributions and validate their effectiveness in resolving distinctive dynamic patterns associated with different bearing faults. Based on this, we design a time-frequency convolutional neural network (TF-CNN) to diagnose various faults in rolling-element bearings. Our experimental findings undeniably demonstrate the superior performance of TF-CNN in comparison to recently developed techniques. They also assert its versatility in capturing fault-relevant non-stationary features that couple with speed changes and show its exceptional resilience to noise, consistently surpassing competing methods across various signal-to-noise ratios and performance metrics. Altogether, the TF-CNN achieves substantial accuracy improvements up to 15%, in severe noise conditions.

Real-Time Vibration-Based Bearing Fault Diagnosis Under Time-Varying Speed Conditions

Nov 30, 2023

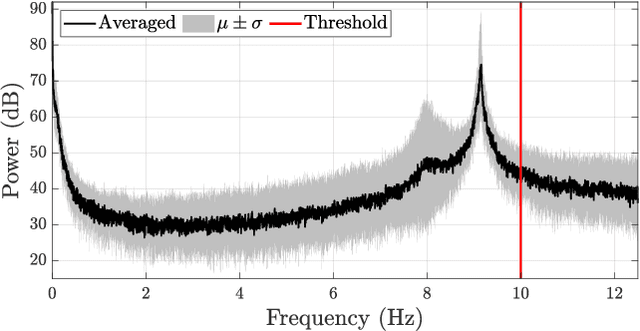

Abstract:Detection of rolling-element bearing faults is crucial for implementing proactive maintenance strategies and for minimizing the economic and operational consequences of unexpected failures. However, many existing techniques are developed and tested under strictly controlled conditions, limiting their adaptability to the diverse and dynamic settings encountered in practical applications. This paper presents an efficient real-time convolutional neural network (CNN) for diagnosing multiple bearing faults under various noise levels and time-varying rotational speeds. Additionally, we propose a novel Fisher-based spectral separability analysis (SSA) method to elucidate the effectiveness of the designed CNN model. We conducted experiments on both healthy bearings and bearings afflicted with inner race, outer race, and roller ball faults. The experimental results show the superiority of our model over the current state-of-the-art approach in three folds: it achieves substantial accuracy gains of up to 15.8%, it is robust to noise with high performance across various signal-to-noise ratios, and it runs in real-time with processing durations five times less than acquisition. Additionally, by using the proposed SSA technique, we offer insights into the model's performance and underscore its effectiveness in tackling real-world challenges.

Real-Time Damage Detection in Fiber Lifting Ropes Using Convolutional Neural Networks

Feb 23, 2023Abstract:The health and safety hazards posed by worn crane lifting ropes mandate periodic inspection for damage. This task is time-consuming, prone to human error, halts operation, and may result in the premature disposal of ropes. Therefore, we propose using deep learning and computer vision methods to automate the process of detecting damaged ropes. Specifically, we present a novel vision-based system for detecting damage in synthetic fiber rope images using convolutional neural networks (CNN). We use a camera-based apparatus to photograph the lifting rope's surface, while in operation, and capture the progressive wear-and-tear as well as the more significant degradation in the rope's health state. Experts from Konecranes annotate the collected images in accordance with the rope's condition; normal or damaged. Then, we pre-process the images, design a CNN model in a systematic manner, evaluate its detection and prediction performance, analyze its computational complexity, and compare it with various other models. Experimental results show the proposed model outperforms other techniques with 96.4% accuracy, 95.8% precision, 97.2% recall, 96.5% F1-score, and 99.2% AUC. Besides, they demonstrate the model's real-time operation, low memory footprint, robustness to various environmental and operational conditions, and adequacy for deployment in industrial systems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge