Mauricio Jacobo-Romero

Analysis of business process automation as linear time-invariant system network

Feb 09, 2023

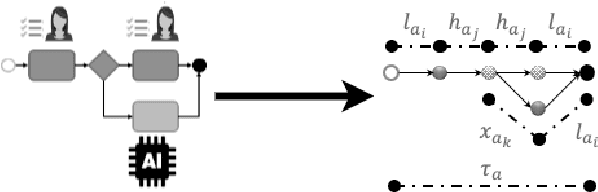

Abstract:In this work, we examined Business Process (BP) production as a signal; this novel approach explores a BP workflow as a linear time-invariant (LTI) system. We analysed BP productivity in the frequency domain; this standpoint examines how labour and capital act as BP input signals and how their fundamental frequencies affect BP production. Our research also proposes a simulation framework of a BP in the frequency domain for estimating productivity gains due to the introduction of automation steps. Our ultimate goal was to supply evidence to address Solow's Paradox.

Estimating productivity gains in digital automation

Oct 08, 2022

Abstract:This paper proposes a novel productivity estimation model to evaluate the effects of adopting Artificial Intelligence (AI) components in a production chain. Our model provides evidence to address the "AI's" Solow's Paradox. We provide (i) theoretical and empirical evidence to explain Solow's dichotomy; (ii) a data-driven model to estimate and asses productivity variations; (iii) a methodology underpinned on process mining datasets to determine the business process, BP, and productivity; (iv) a set of computer simulation parameters; (v) and empirical analysis on labour-distribution. These provide data on why we consider AI Solow's paradox a consequence of metric mismeasurement.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge