Maryam Soleymani

Towards Improving Workers' Safety and Progress Monitoring of Construction Sites Through Construction Site Understanding

Oct 27, 2022

Abstract:An important component of computer vision research is object detection. In recent years, there has been tremendous progress in the study of construction site images. However, there are obvious problems in construction object detection, including complex backgrounds, varying-sized objects, and poor imaging quality. In the state-of-the-art approaches, elaborate attention mechanisms are developed to handle space-time features, but rarely address the importance of channel-wise feature adjustments. We propose a lightweight Optimized Positioning (OP) module to improve channel relation based on global feature affinity association, which can be used to determine the Optimized weights adaptively for each channel. OP first computes the intermediate optimized position by comparing each channel with the remaining channels for a given set of feature maps. A weighted aggregation of all the channels will then be used to represent each channel. The OP-Net module is a general deep neural network module that can be plugged into any deep neural network. Algorithms that utilize deep learning have demonstrated their ability to identify a wide range of objects from images nearly in real time. Machine intelligence can potentially benefit the construction industry by automatically analyzing productivity and monitoring safety using algorithms that are linked to construction images. The benefits of on-site automatic monitoring are immense when it comes to hazard prevention. Construction monitoring tasks can also be automated once construction objects have been correctly recognized. Object detection task in construction site images is experimented with extensively to demonstrate its efficacy and effectiveness. A benchmark test using SODA demonstrated that our OP-Net was capable of achieving new state-of-the-art performance in accuracy while maintaining a reasonable computational overhead.

Autonomous Resource Management in Construction Companies Using Deep Reinforcement Learning Based on IoT

Aug 17, 2022

Abstract:Resource allocation is one of the most critical issues in planning construction projects, due to its direct impact on cost, time, and quality. There are usually specific allocation methods for autonomous resource management according to the projects objectives. However, integrated planning and optimization of utilizing resources in an entire construction organization are scarce. The purpose of this study is to present an automatic resource allocation structure for construction companies based on Deep Reinforcement Learning (DRL), which can be used in various situations. In this structure, Data Harvesting (DH) gathers resource information from the distributed Internet of Things (IoT) sensor devices all over the companys projects to be employed in the autonomous resource management approach. Then, Coverage Resources Allocation (CRA) is compared to the information obtained from DH in which the Autonomous Resource Management (ARM) determines the project of interest. Likewise, Double Deep Q-Networks (DDQNs) with similar models are trained on two distinct assignment situations based on structured resource information of the company to balance objectives with resource constraints. The suggested technique in this paper can efficiently adjust to large resource management systems by combining portfolio information with adopted individual project information. Also, the effects of important information processing parameters on resource allocation performance are analyzed in detail. Moreover, the results of the generalizability of management approaches are presented, indicating no need for additional training when the variables of situations change.

Construction material classification on imbalanced datasets for construction monitoring automation using Vision Transformer (ViT) architecture

Aug 21, 2021

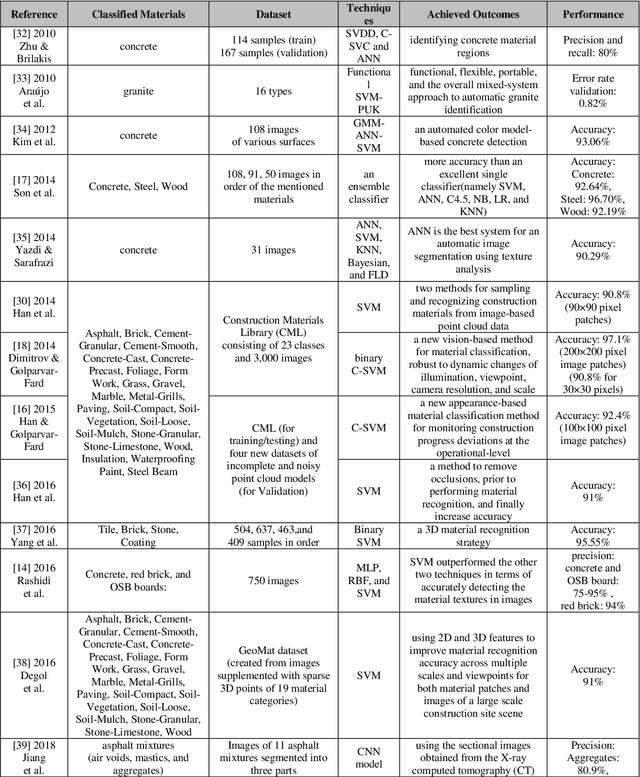

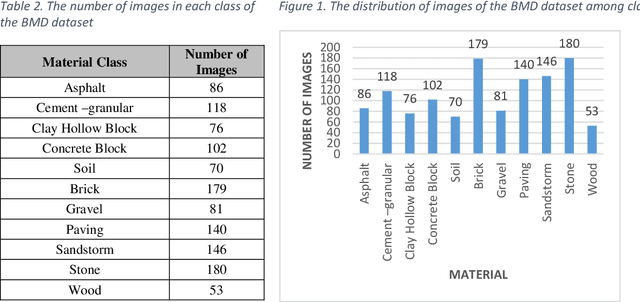

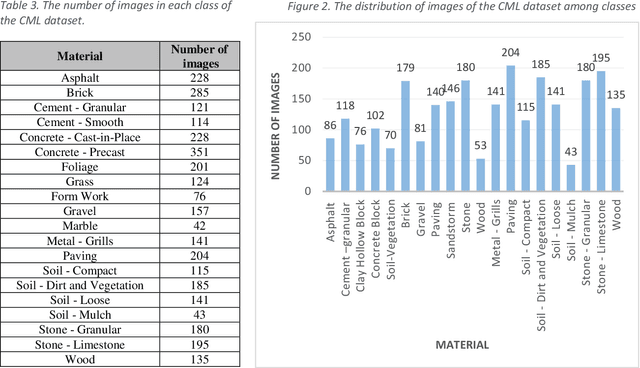

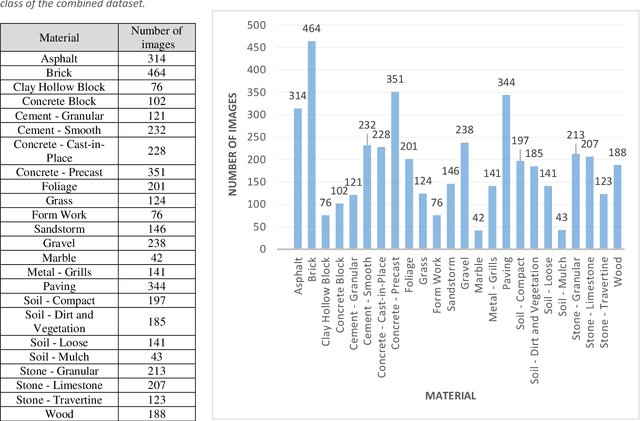

Abstract:Nowadays, automation is a critical topic due to its significant impacts on the productivity of construction projects. Utilizing automation in this industry brings about great results, such as remarkable improvements in the efficiency, quality, and safety of construction activities. The scope of automation in construction includes a wide range of stages, and monitoring construction projects is no exception. Additionally, it is of great importance in project management since an accurate and timely assessment of project progress enables managers to quickly identify deviations from the schedule and take the required actions at the right time. In this stage, one of the most important tasks is to daily keep track of the project progress, which is very time-consuming and labor-intensive, but automation has facilitated and accelerated this task. It also eliminated or at least decreased the risk of many dangerous tasks. In this way, the first step of construction automation is to detect used materials in a project site automatically. In this paper, a novel deep learning architecture is utilized, called Vision Transformer (ViT), for detecting and classifying construction materials. To evaluate the applicability and performance of the proposed method, it is trained and tested on three large imbalanced datasets, namely Construction Material Library (CML) and Building Material Dataset (BMD), used in the previous papers, as well as a new dataset created by combining them. The achieved results revealed an accuracy of 100 percent in all parameters and also in each material category. It is believed that the proposed method provides a novel and robust tool for detecting and classifying different material types.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge