Marcus Ritt

Exact and Heuristic Methods for the Assembly Line Worker Assignment and Balancing Problem

Aug 01, 2013

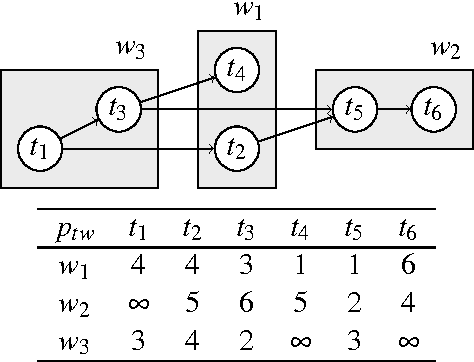

Abstract:In traditional assembly lines, it is reasonable to assume that task execution times are the same for each worker. However, in sheltered work centres for disabled this assumption is not valid: some workers may execute some tasks considerably slower or even be incapable of executing them. Worker heterogeneity leads to a problem called the assembly line worker assignment and balancing problem (ALWABP). For a fixed number of workers the problem is to maximize the production rate of an assembly line by assigning workers to stations and tasks to workers, while satisfying precedence constraints between the tasks. This paper introduces new heuristic and exact methods to solve this problem. We present a new MIP model, propose a novel heuristic algorithm based on beam search, as well as a task-oriented branch-and-bound procedure which uses new reduction rules and lower bounds for solving the problem. Extensive computational tests on a large set of instances show that these methods are effective and improve over existing ones.

Simple heuristics for the assembly line worker assignment and balancing problem

Feb 22, 2012

Abstract:We propose simple heuristics for the assembly line worker assignment and balancing problem. This problem typically occurs in assembly lines in sheltered work centers for the disabled. Different from the classical simple assembly line balancing problem, the task execution times vary according to the assigned worker. We develop a constructive heuristic framework based on task and worker priority rules defining the order in which the tasks and workers should be assigned to the workstations. We present a number of such rules and compare their performance across three possible uses: as a stand-alone method, as an initial solution generator for meta-heuristics, and as a decoder for a hybrid genetic algorithm. Our results show that the heuristics are fast, they obtain good results as a stand-alone method and are efficient when used as a initial solution generator or as a solution decoder within more elaborate approaches.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge