María Jesús Gómez García

Transformer Vibration Forecasting for Advancing Rail Safety and Maintenance 4.0

Jan 20, 2025

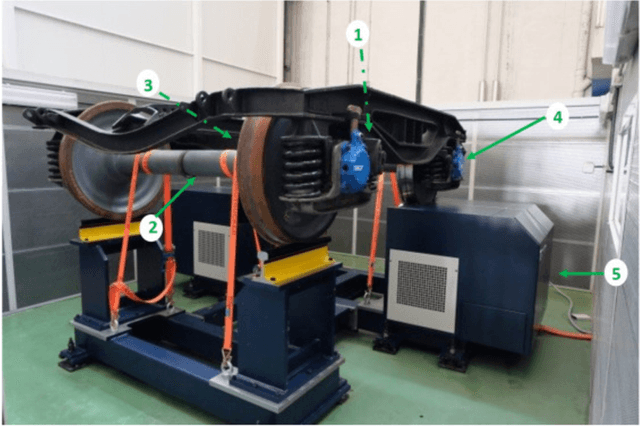

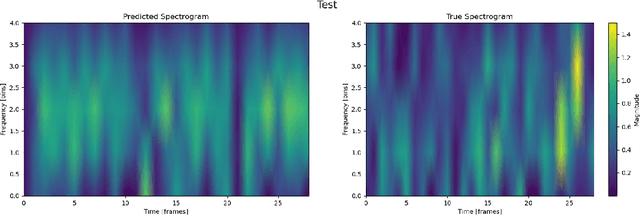

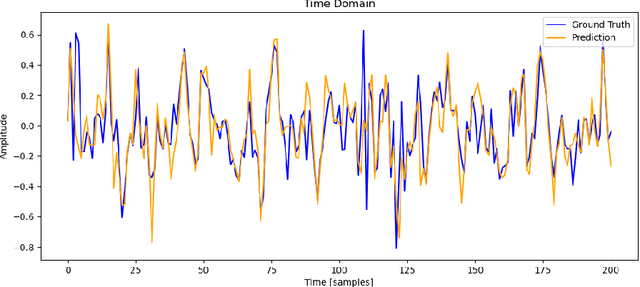

Abstract:Maintaining railway axles is critical to preventing severe accidents and financial losses. The railway industry is increasingly interested in advanced condition monitoring techniques to enhance safety and efficiency, moving beyond traditional periodic inspections toward Maintenance 4.0. This study introduces a robust Deep Autoregressive solution that integrates seamlessly with existing systems to avert mechanical failures. Our approach simulates and predicts vibration signals under various conditions and fault scenarios, improving dataset robustness for more effective detection systems. These systems can alert maintenance needs, preventing accidents preemptively. We use experimental vibration signals from accelerometers on train axles. Our primary contributions include a transformer model, ShaftFormer, designed for processing time series data, and an alternative model incorporating spectral methods and enhanced observation models. Simulating vibration signals under diverse conditions mitigates the high cost of obtaining experimental signals for all scenarios. Given the non-stationary nature of railway vibration signals, influenced by speed and load changes, our models address these complexities, offering a powerful tool for predictive maintenance in the rail industry.

Detecting train driveshaft damages using accelerometer signals and Differential Convolutional Neural Networks

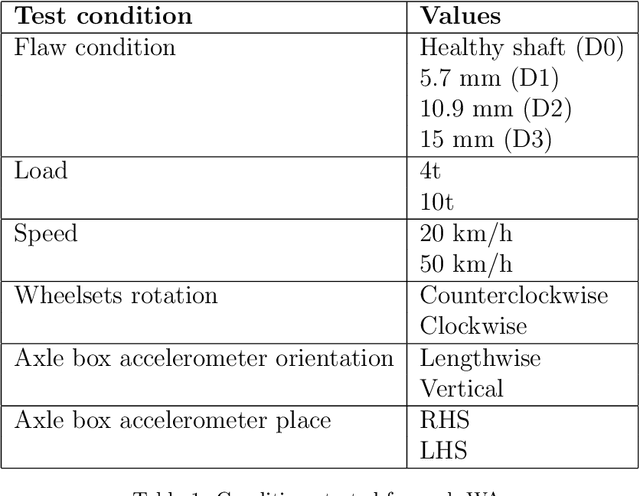

Nov 15, 2022Abstract:Railway axle maintenance is critical to avoid catastrophic failures. Nowadays, condition monitoring techniques are becoming more prominent in the industry to prevent enormous costs and damage to human lives. This paper proposes the development of a railway axle condition monitoring system based on advanced 2D-Convolutional Neural Network (CNN) architectures applied to time-frequency representations of vibration signals. For this purpose, several preprocessing steps and different types of Deep Learning (DL) and Machine Learning (ML) architectures are discussed to design an accurate classification system. The resultant system converts the railway axle vibration signals into time-frequency domain representations, i.e., spectrograms, and, thus, trains a two-dimensional CNN to classify them depending on their cracks. The results showed that the proposed approach outperforms several alternative methods tested. The CNN architecture has been tested in 3 different wheelset assemblies, achieving AUC scores of 0.93, 0.86, and 0.75 outperforming any other architecture and showing a high level of reliability when classifying 4 different levels of defects.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge